Screen printer and screen printing method

A technology of screen printing device and printing table, which is applied in the direction of screen printing machine, printing, printing machine, etc., can solve the problems of cost increase, complex transmission system, process complexity, etc., and achieve the effect of preventing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

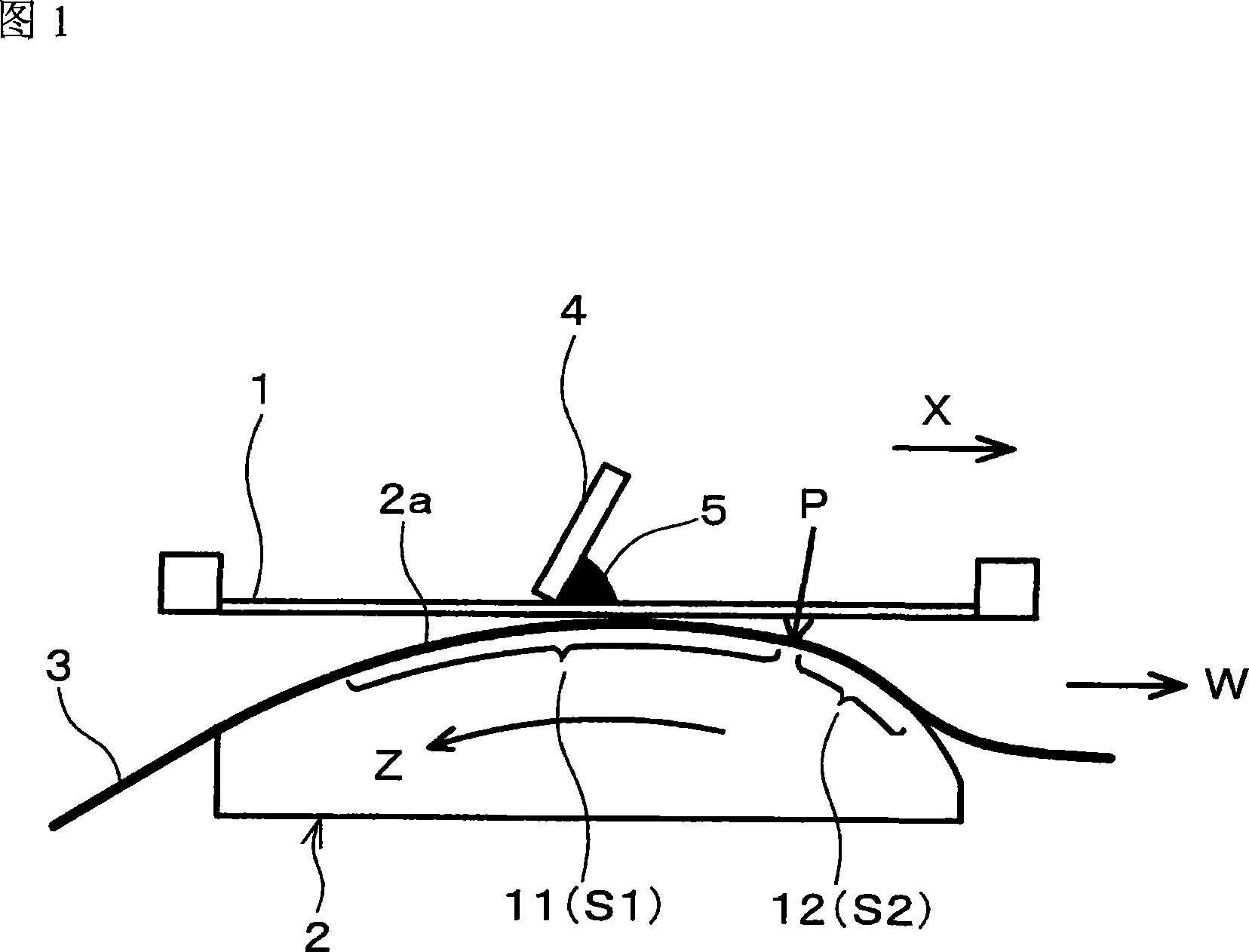

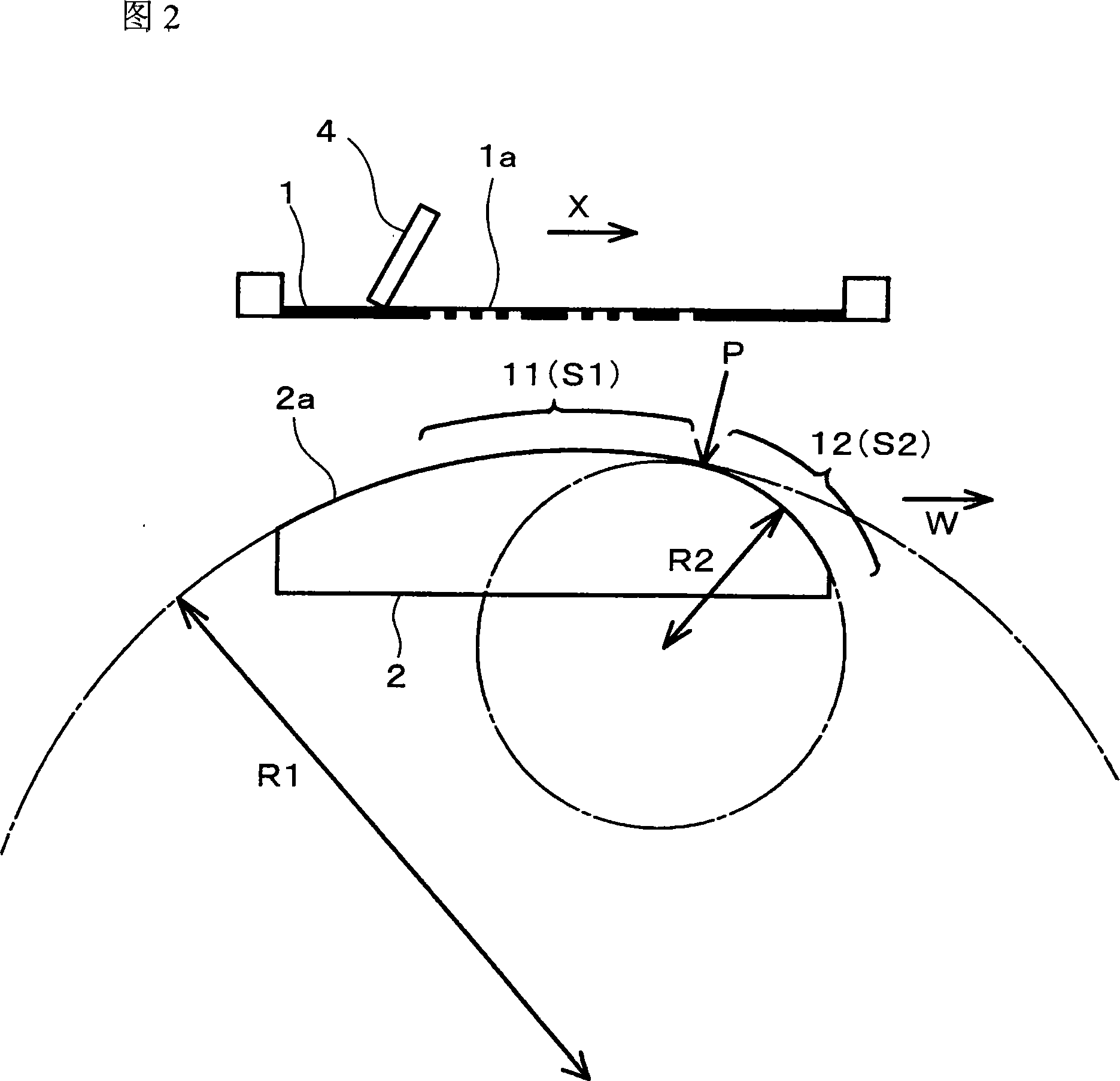

[0079] FIG. 1 is a diagram showing a screen printing apparatus of one embodiment of the present invention. This screen printing device is provided with printing mask 1, printing table 2 and squeegee 4; The surface (upper surface) 2a of printing table 2 opposite to printing mask 1 has convex curved surface shape, and printing table 2 is rotatable, So that its predetermined area can face the printing mask 1; the squeegee 4 presses the printing mask 1 on the printed matter 3 placed on the upper surface (opposite surface) 2a of the printing table 2, and simultaneously prints Slide on Mask 1.

[0080] In this screen printing device, when the squeegee 4 slides on the printing mask 1, the printing table 2 rotates, and the printing area of the elongated object 3 to be printed on the upper surface 2a of the printing table 2 is abutted against In the area corresponding to the sliding position of the squeegee 4 of the printing mask 1 , the pushing force of the squeegee 4 presses the p...

Embodiment 2

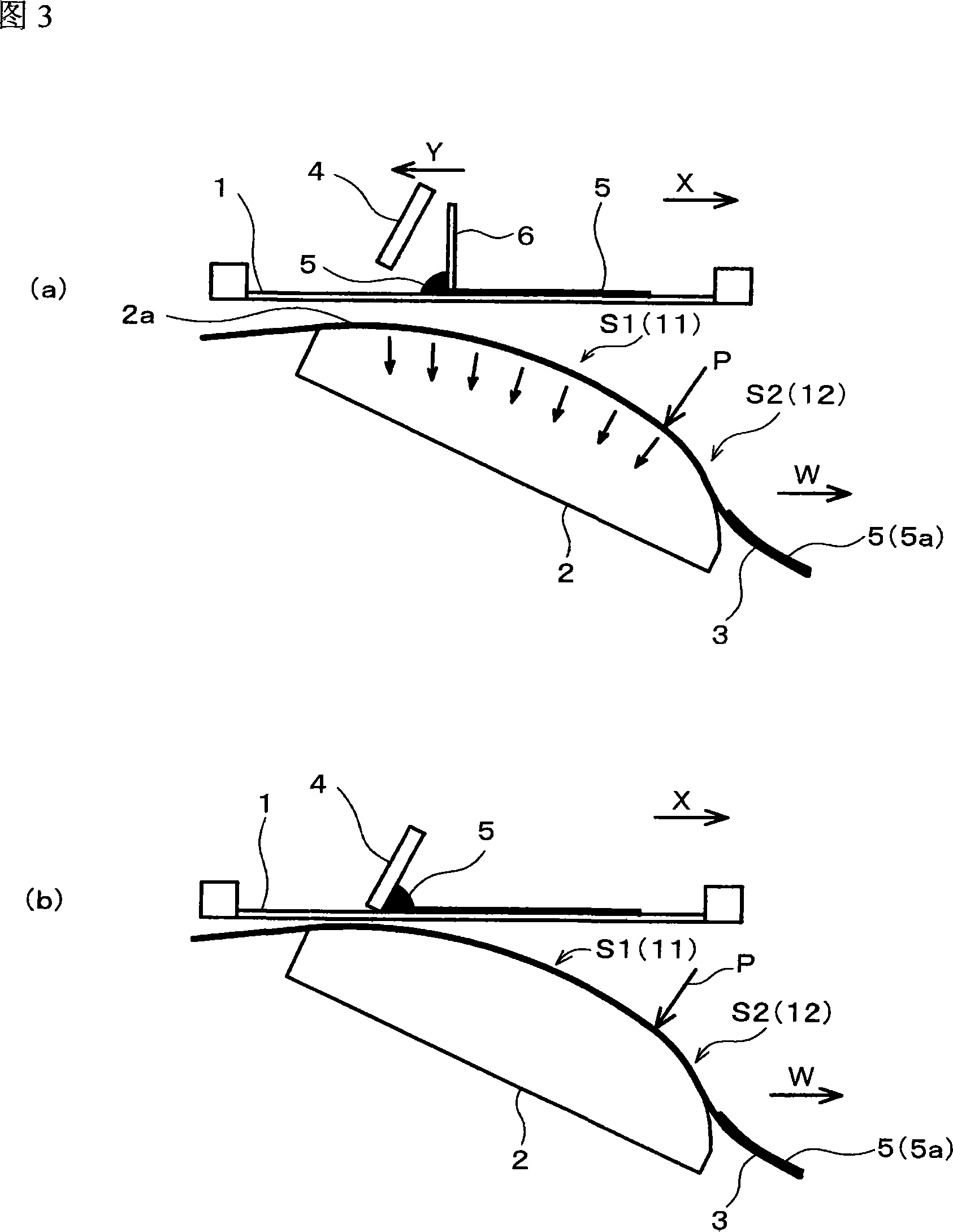

[0098] Fig. 5(a) is a configuration diagram of a main part of a screen printing device according to another embodiment (embodiment 2) of the present invention. As shown in Figure 5 (a), in the screen printing device of this embodiment 2, the surface (upper surface) 2a of the printing table 2 facing the printing mask 1 corresponds to the position of the squeegee 4 on the printing mask. The area S1 of the squeegee sliding portion (squeegee sliding area) 11 that slides on the mold 1 has an arc-shaped cross-sectional shape, but the area of the printing table 2 corresponding to the end of the sliding of the squeegee 4 on the printing mask 1 is In the region S2 of the squeegee non-sliding portion 12 of the printing end portion P (near the squeegee sliding end portion) S2, a notch 13 is formed such that the upper surface 2a of the printing table is cut away.

[0099] Use the screen printing device that has formed the printing table 2 of gap 13 on the upper surface 2a like this, mak...

Embodiment 3

[0103] Fig. 6 is a configuration diagram of main parts of a screen printing device according to another embodiment (embodiment 3) of the present invention. As shown in FIG. 6, in the screen printing device of this embodiment 3, the surface (upper surface) 2a of the printing table 2 facing the printing mask 1 corresponds to the position of the squeegee 4 on the printing mask 1. The cross section of the area S1 of the sliding squeegee sliding portion (squeegee sliding area) 11 has an arc-like shape corresponding to the end portion of the area S1 of the squeegee sliding portion (squeegee sliding area) 11, that is, the scraper. The ink plate sliding terminal portion P is configured as an end portion (terminal portion) of the printing table 2 .

[0104] Using a screen printing device having a printing table 2 whose terminal portion corresponding to the area S1 of the squeegee sliding portion 11 constitutes the terminal portion of the printing table 2, the area S1 corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com