Attachment structure

A technology for connecting structures and components, which is applied in the direction of handwheels, steering controls installed on vehicles, handlebars, etc., can solve the problems of collision between the rotary connector device 81 and the combination switch 86, damage to the locking claw, and detachment, so as to promote Operability and fixation reliability, effective connection, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

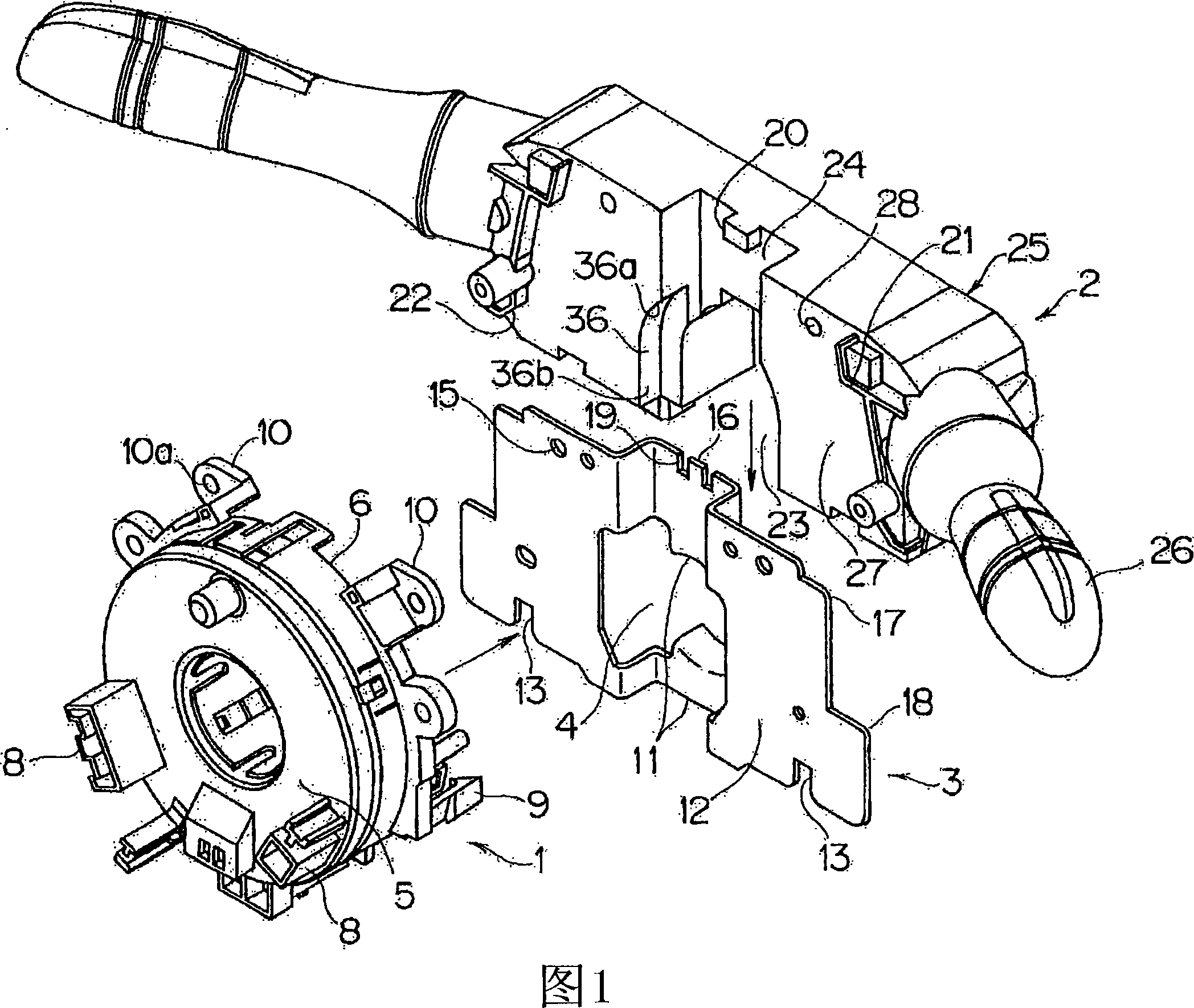

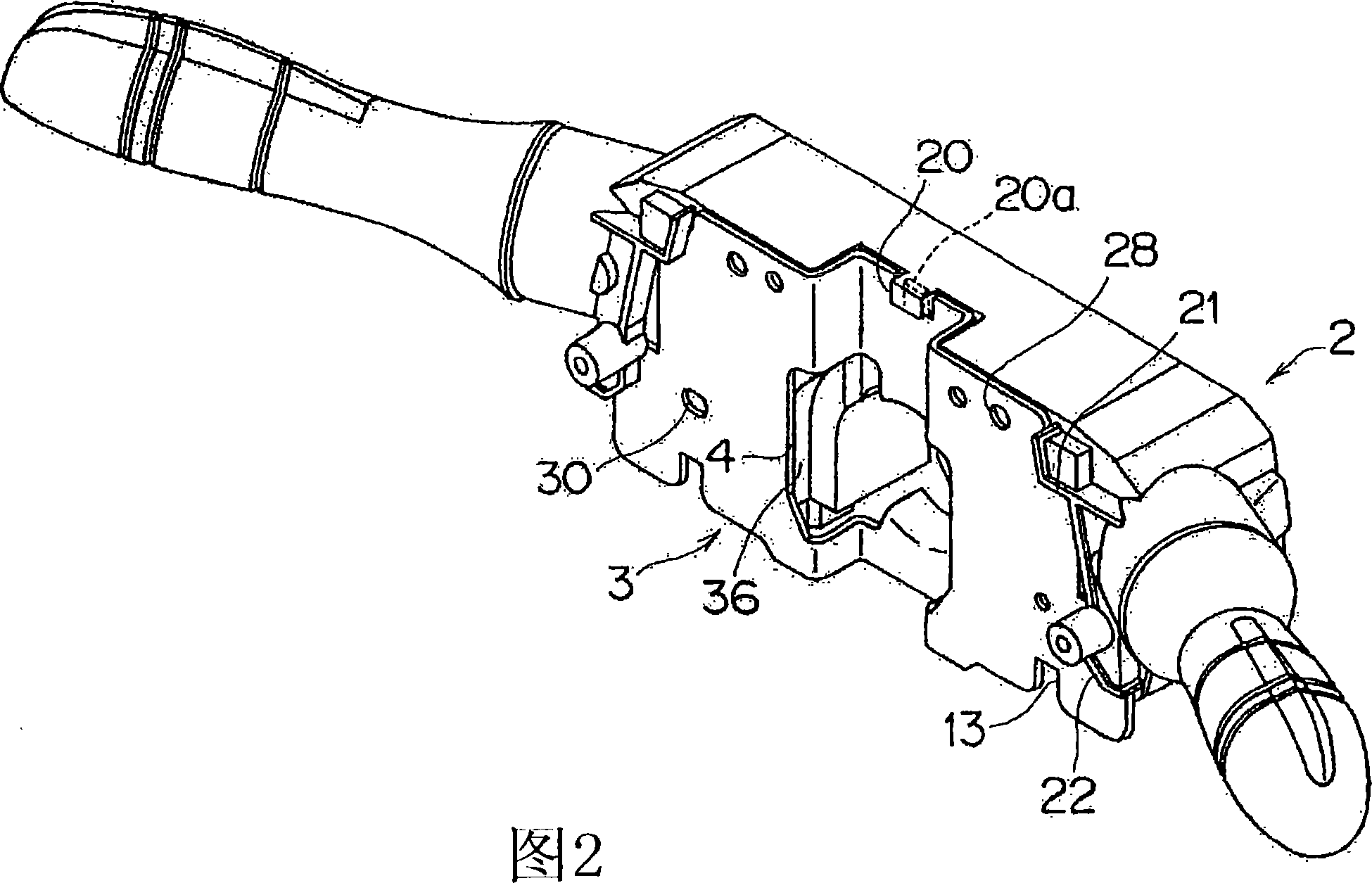

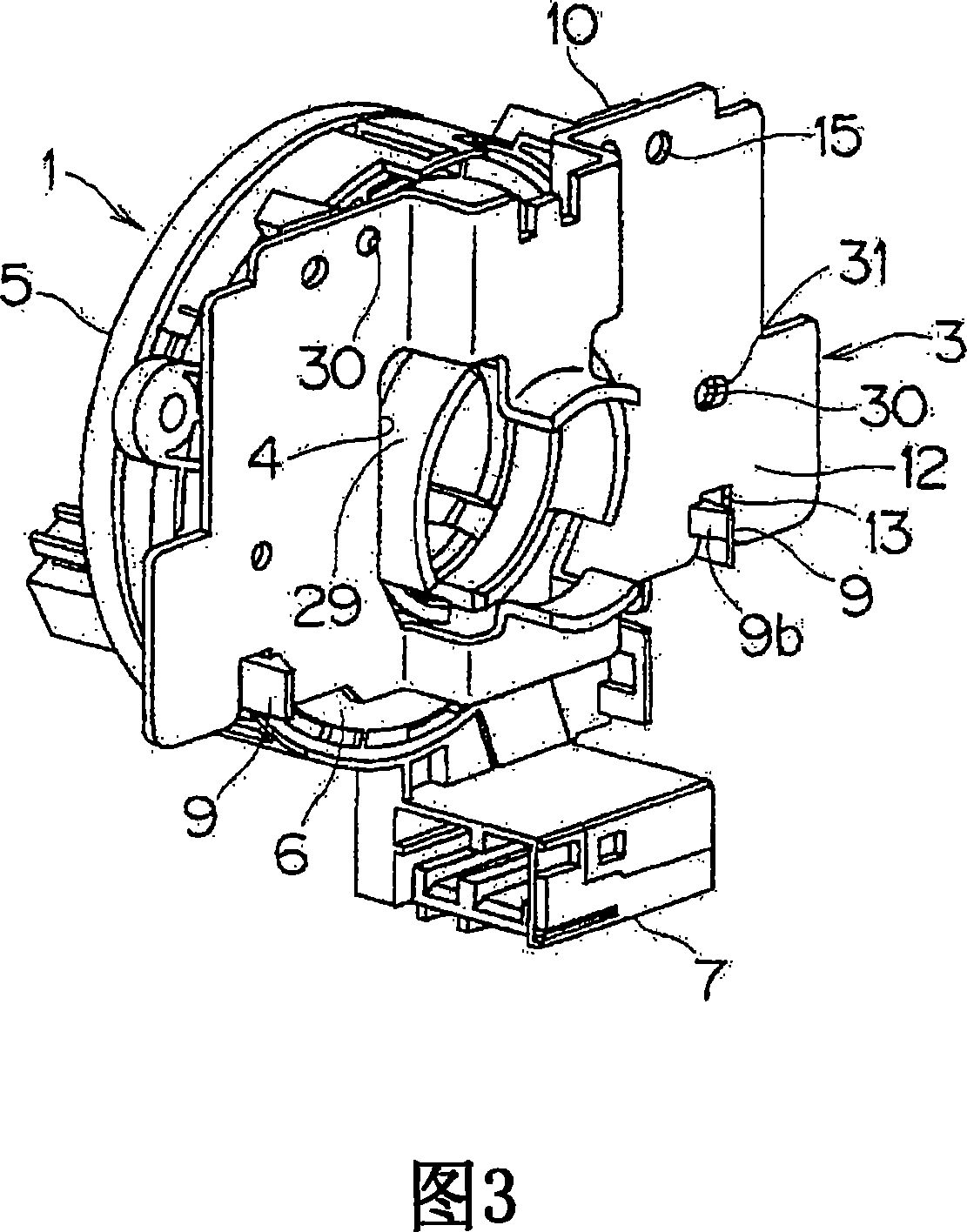

[0050] 1 to 5 show an embodiment of a structure coupling a rotary connector device and a combination switch according to the present invention.

[0051]As shown in FIG. 1 , the rotary connector device 1 and the combination switch 2 are fixed to each other by a bracket 3 . A steering shaft (not shown) is inserted into a hole portion 4 at the center of the bracket 3, and the combination switch 2 is fixed to a resin cover (not shown) which is cylindrical around the steering wheel.

[0052] In the basic structure of the rotary connector device 1, a substantially helical flat wire harness (not shown) is contained in the inner side of a case including a fixed cover 6 and a rotary cover 5, both of which are ring-shaped and made of synthetic resin. production. One end of the flat wire harness is connected to a connector 7 ( FIG. 3 ) on the side of the fixed cover, and the other end of the flat wire harness is connected to a connector 8 on the side of the rotating cover.

[0053] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com