Centrifugal pump mouth ring sealing device

A ring seal and pump port technology, applied in the field of centrifugal pump port ring seal structure, can solve the problems of limited application range, short service life, large radial size, etc., and achieve long service life, small overall radial size, and reliable sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

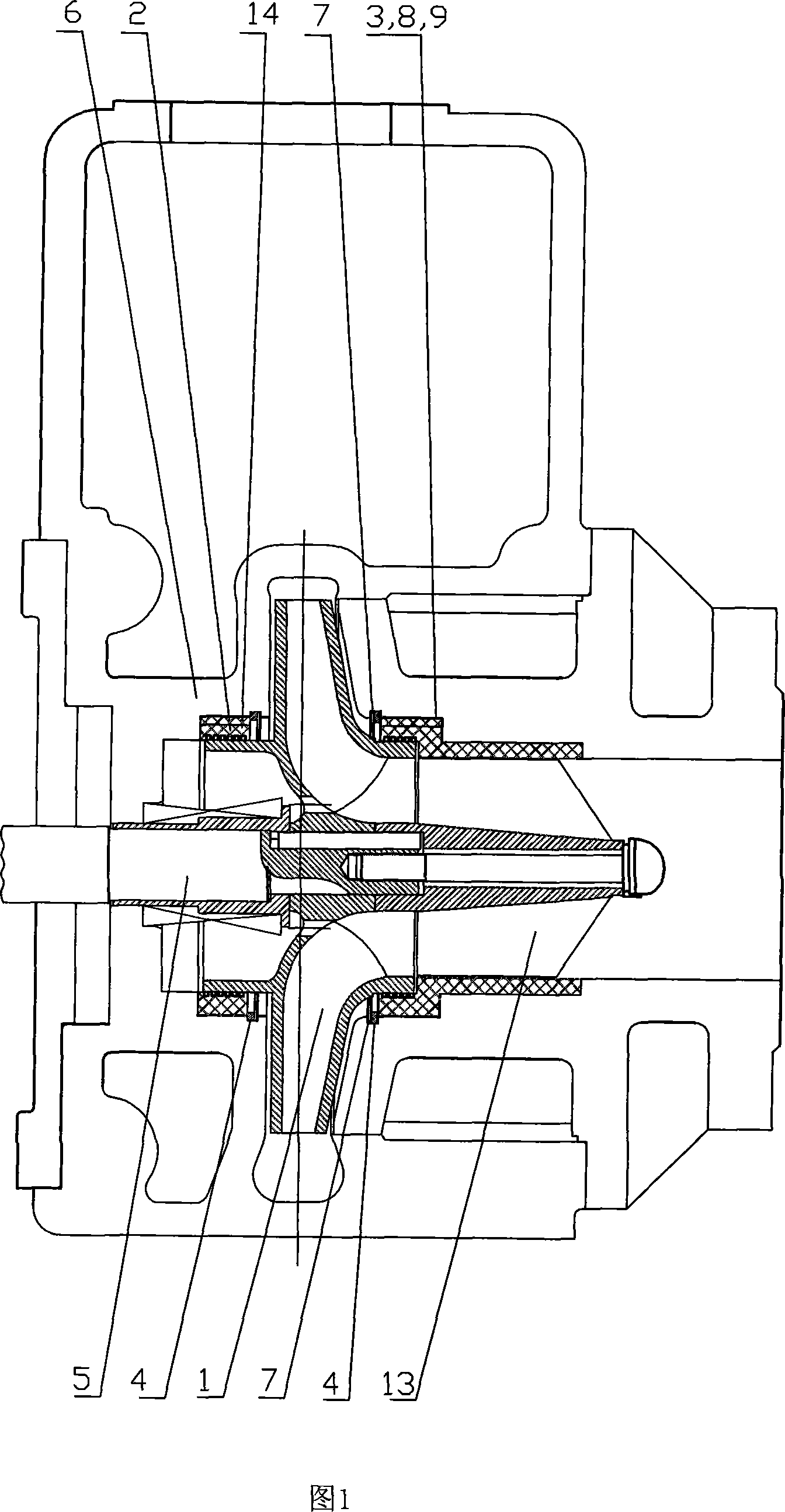

[0018] The structure of the first sealing device of the present invention is shown in Figure 1. It includes the impeller 1, the sealing ring 2, the retaining ring 4, the retaining ring groove 7, and the fastening device; the retaining ring groove 7 is arranged on the inner side of the pump housing 6, and the retaining ring 4 It is arranged in the retaining ring groove 7 to prevent the sealing ring 2 from loosening in the axial direction; the fastening device is arranged between the pump casing and the impeller to fix the sealing ring in the direction of rotation. It includes a fixed key 3 and an axial arrangement The outer groove 8 on the inner side of the pump housing 6 and the inner groove 9 axially arranged on the outer side of the sealing ring 2, and the fixed key 3 is arranged between the outer groove 8 and the inner groove 9. The pump shaft 5 and the gearbox output shaft are one shaft. The gearbox obtains power from the outside through a coupling. After speed change, the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com