Composite absorption heat pump

An absorption heat pump and heat pump technology, applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems that absorption heat pumps cannot have a wide heating range and high waste heat utilization rate at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

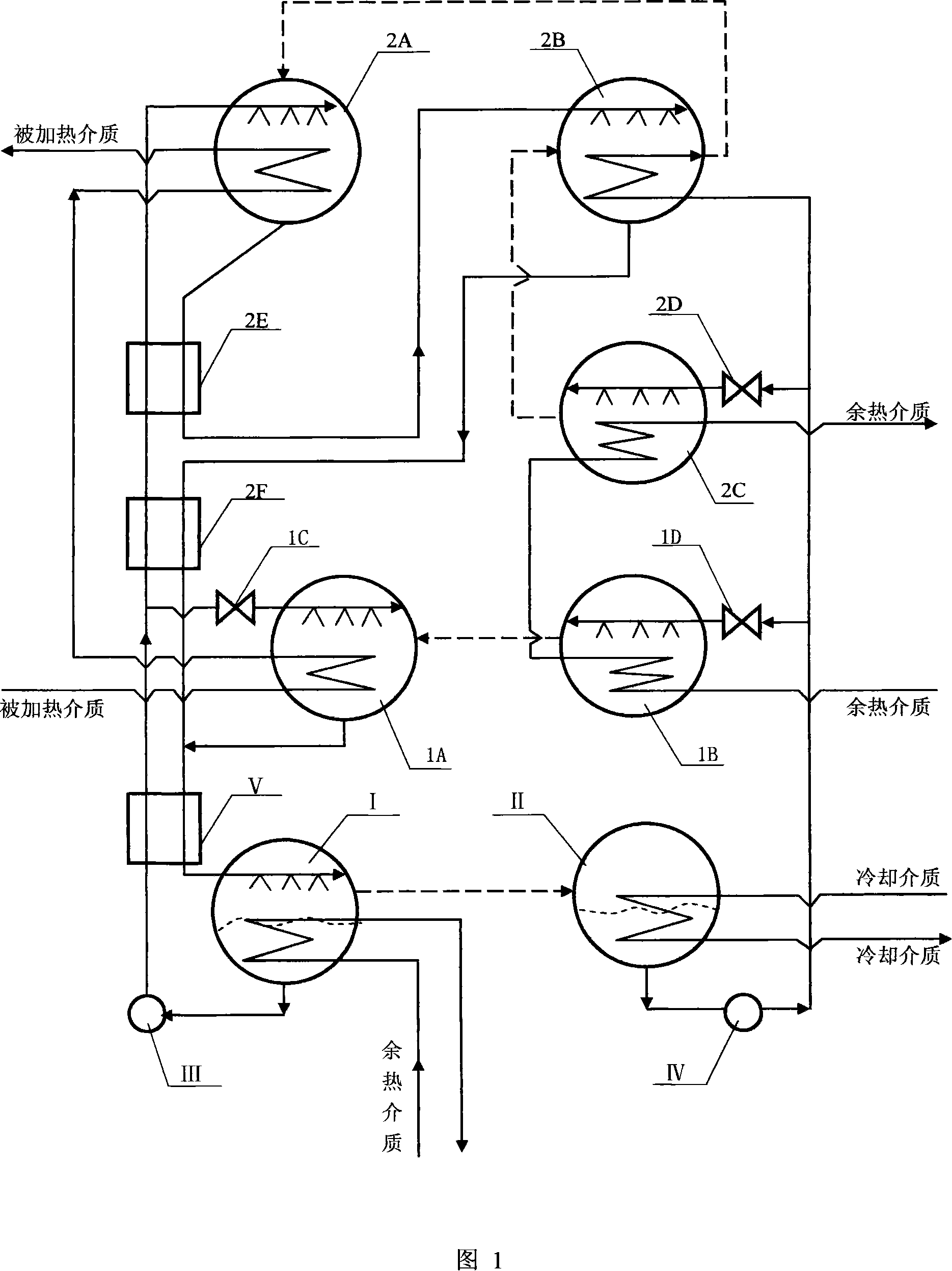

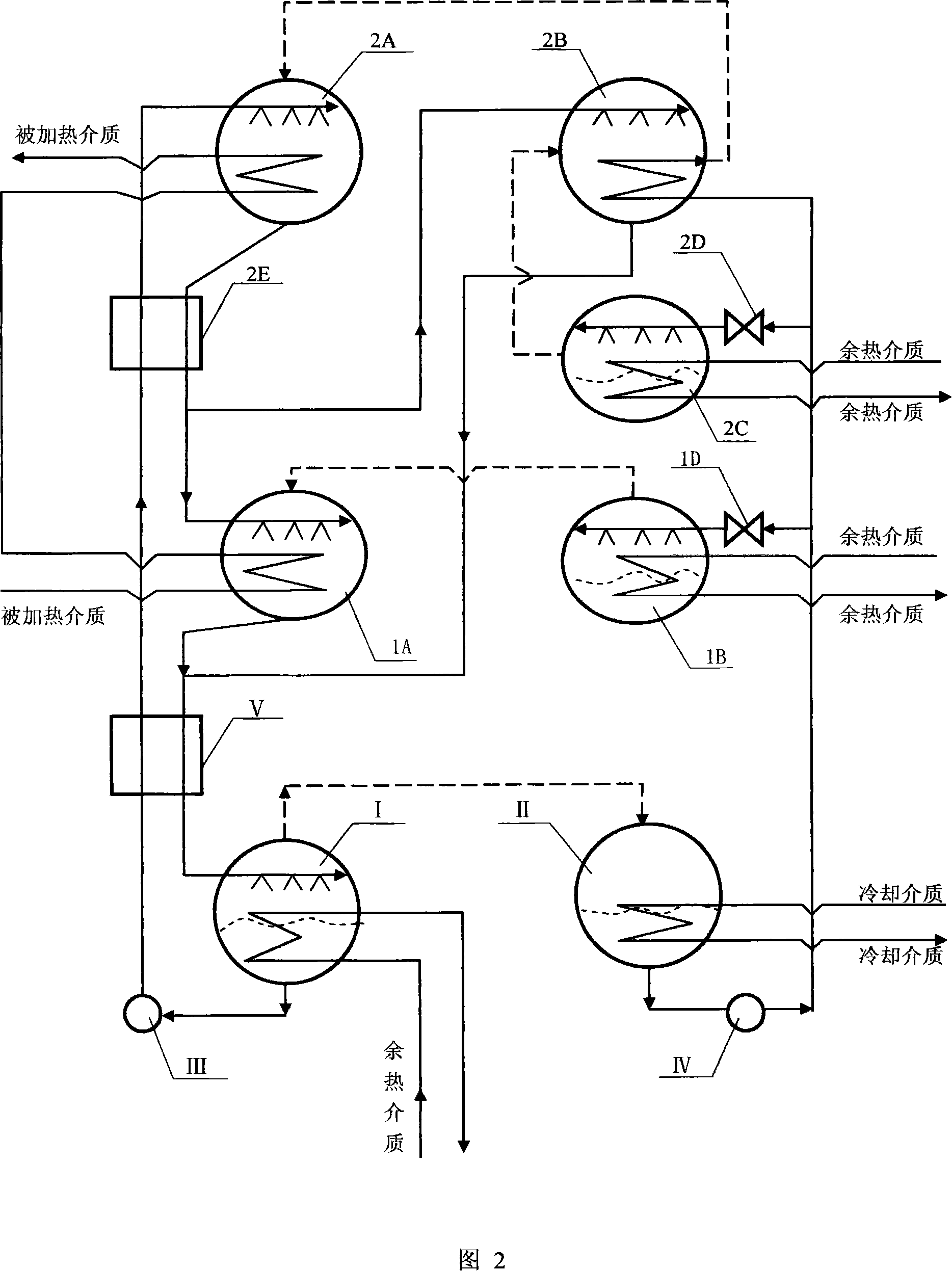

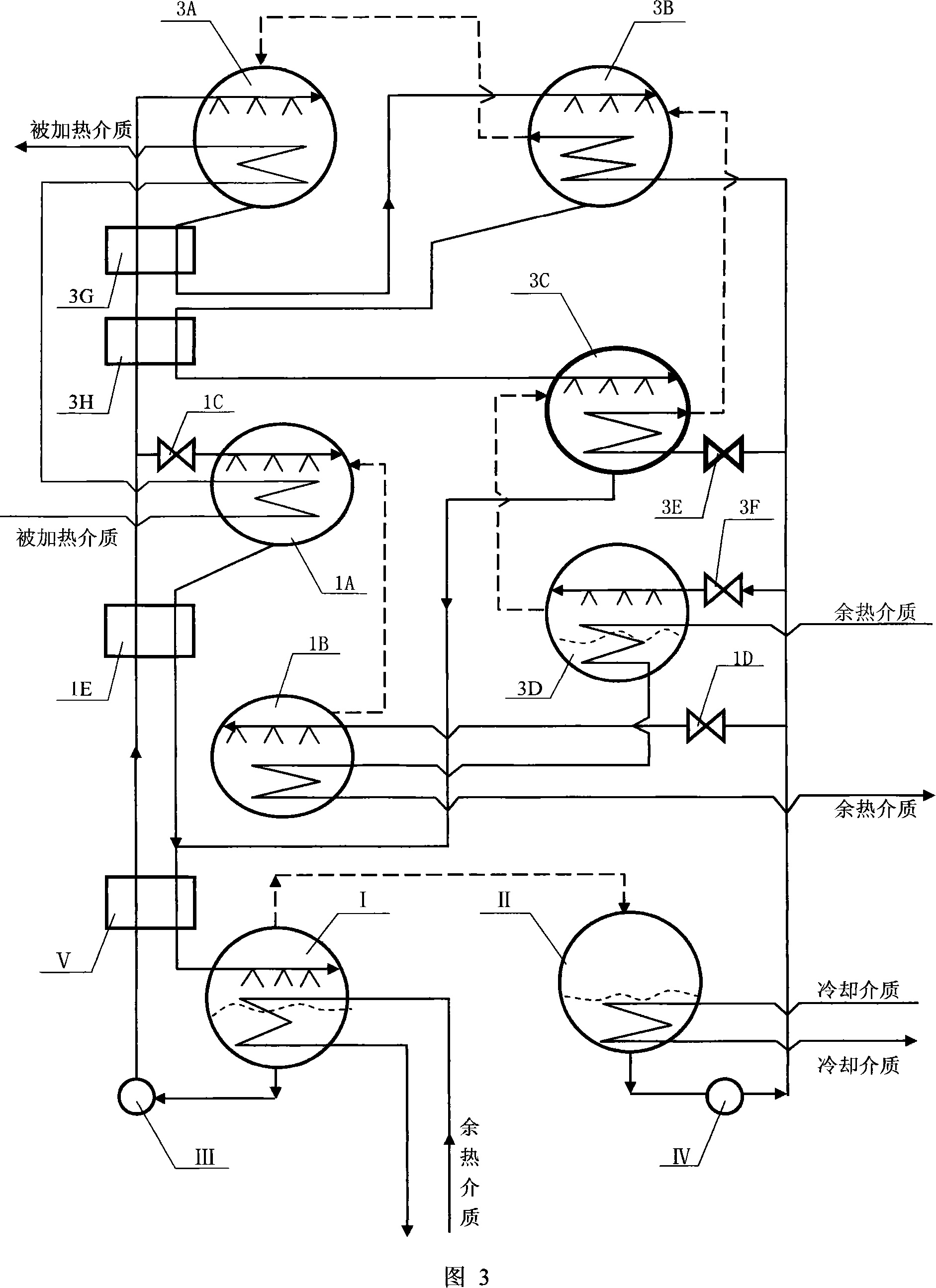

[0025] Take the second type of absorption heat pump provided by the present invention as an example, as shown in Figure 1, the object of the present invention is achieved in this way:

[0026] 1. In terms of structure, the composite heat pump is mainly composed of a common generator I, a common condenser II, a common solution pump III, a common condensate pump IV, a common solution heat exchanger V, a primary absorber 1A, a primary evaporator 1B, Primary pressure regulating valve 1C, primary throttle valve 1D, secondary absorber 2A, secondary absorption-evaporator 2B, secondary evaporator 2C, secondary throttle valve 2D, secondary solution heat exchangers 2E and 2F Composed of; wherein, the common parts and the secondary absorber 2A, the secondary absorption-evaporator 2B, the secondary evaporator 2C, the secondary throttle valve 2D, and the secondary so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com