Fuel battery and its assembly method

A fuel cell stack and fuel cell technology, used in fuel cells, fuel cell components, solid electrolyte fuel cells, etc., can solve problems such as prolonged working hours, excessive internal current impedance of fuel cells, and increased fuel cell volume and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be described by specific specific examples below, so that those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

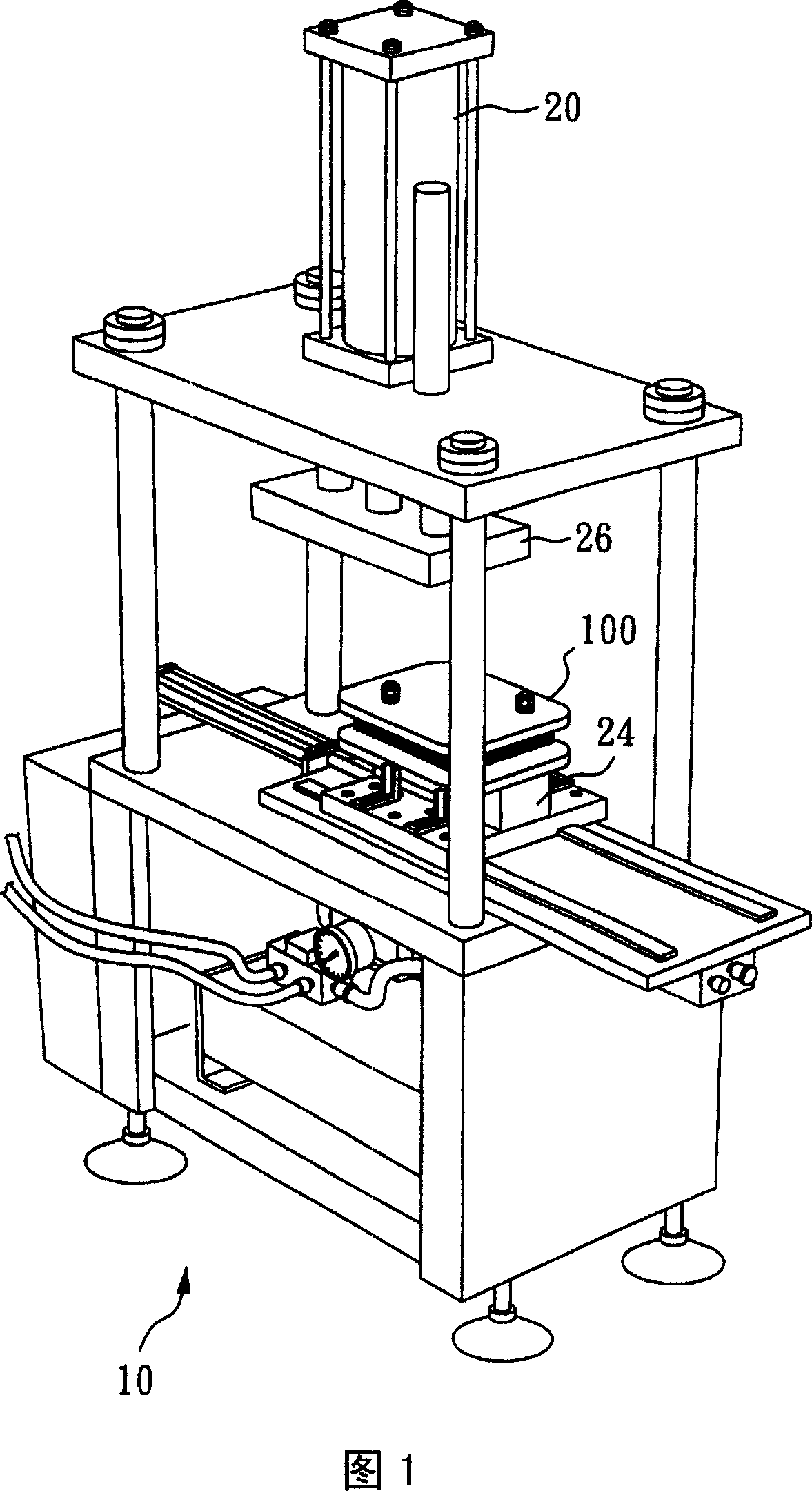

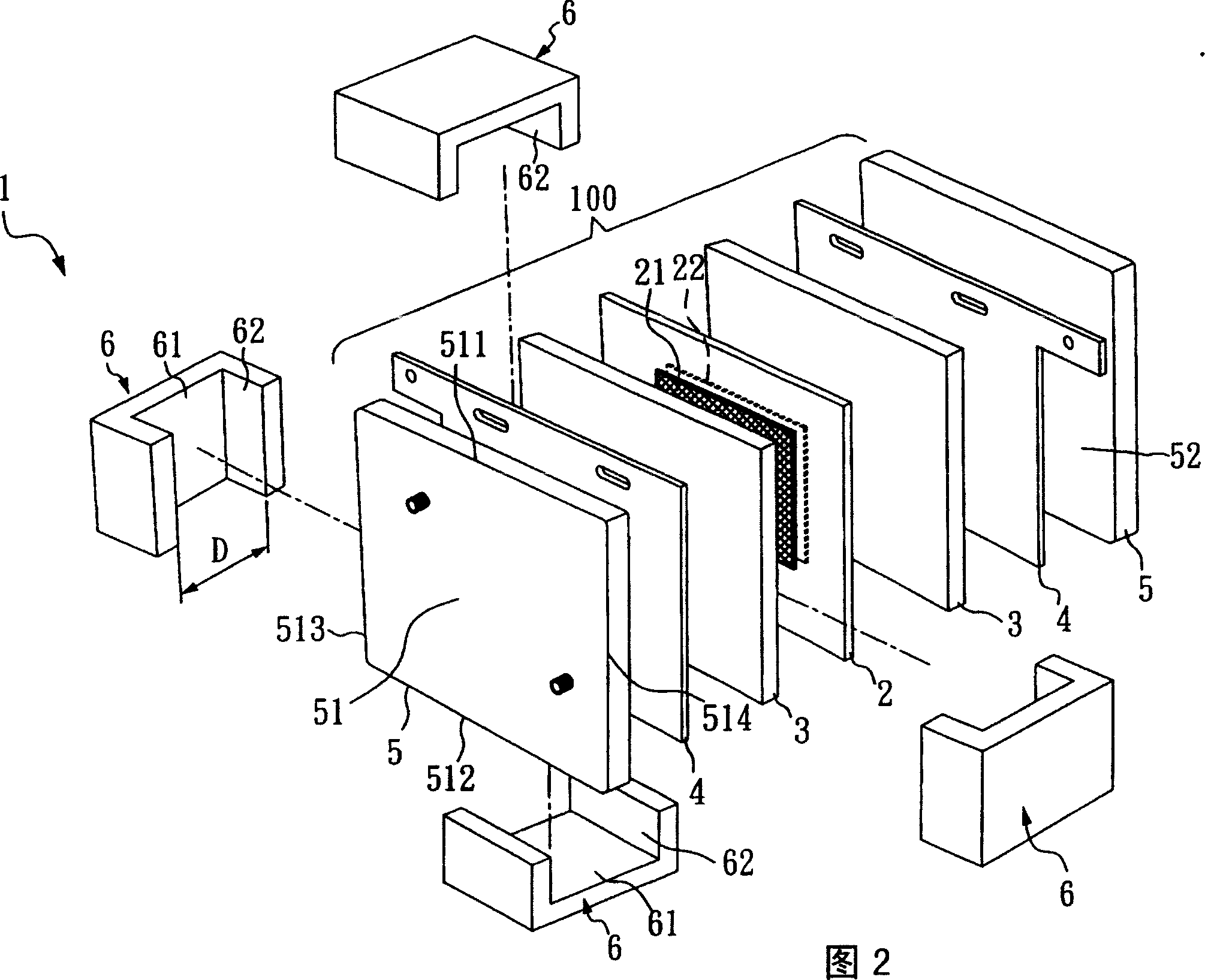

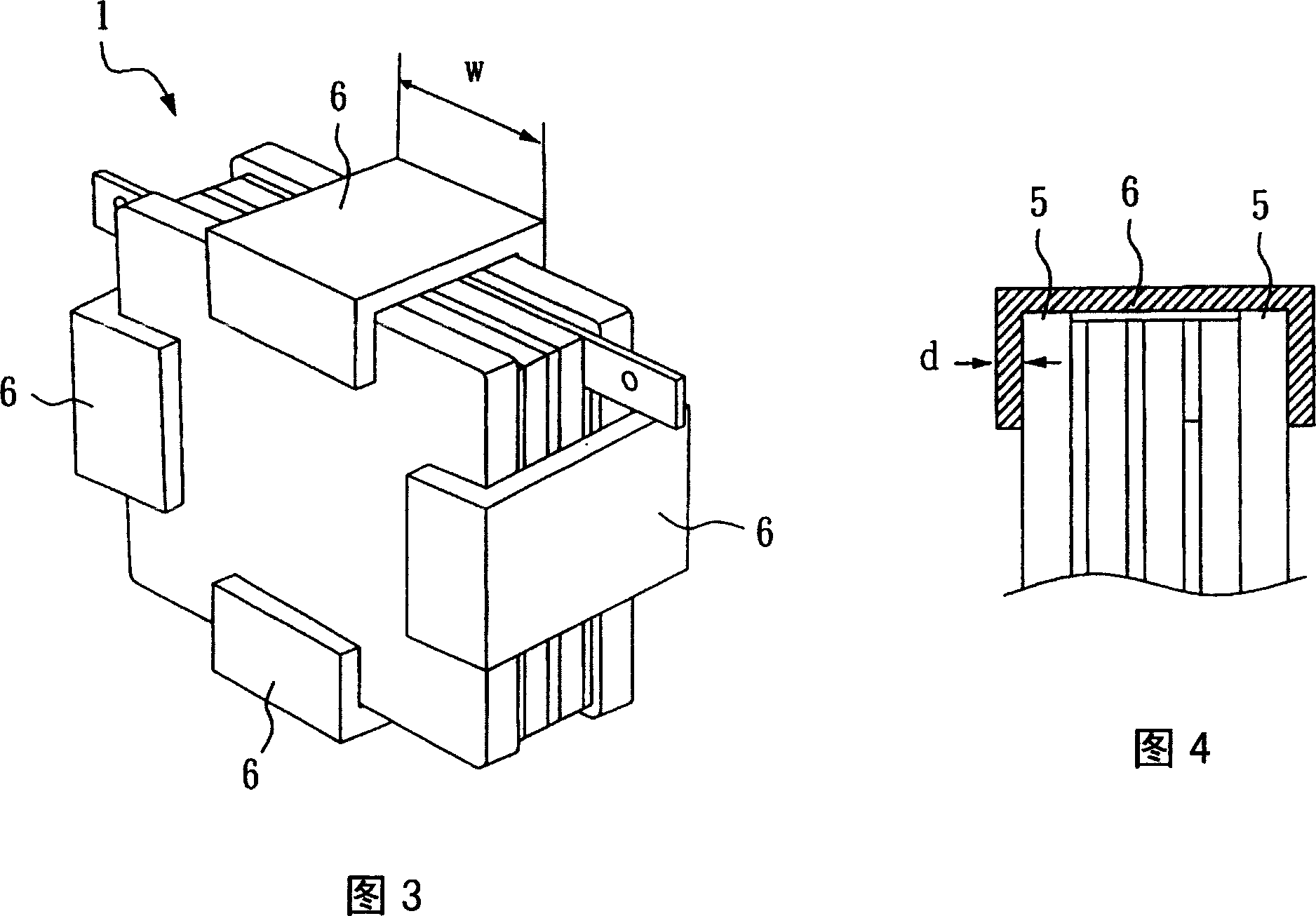

[0033] Regarding the fuel cell 1 of the present invention, please refer to FIG. 2 and FIG. 3 , the fuel cell stack 100 is mainly composed of a membrane electrode set 2, two flow field plates 3, two collector plates 4 and two end plates 5, The membrane electrode group 2 mainly provides the core of the reaction of the fuel cell 1; the flow field plate 3 mainly provides the reaction gas channel and the conduction of electrons; the collector plate 4 mainly provides the electricity generated by the export battery to supply the external load; in addition, the end plate 5 mainly provides clamping of all layers and gas inlet and outlet, and stabilizes the fuel cell 1 .

[0034] In the structure of the fuel cell 1 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com