Joint parts numerically controlled process clamping method and milling tool

A part and clamping technology, which is applied to the CNC machining and clamping method of the main support joint of the aircraft and the field of milling tools, can solve the problems of not opening the processing groove, the milling tool is difficult to design, and is not practical, so as to improve the CNC machining efficiency. , easy to position and fix, simple to design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

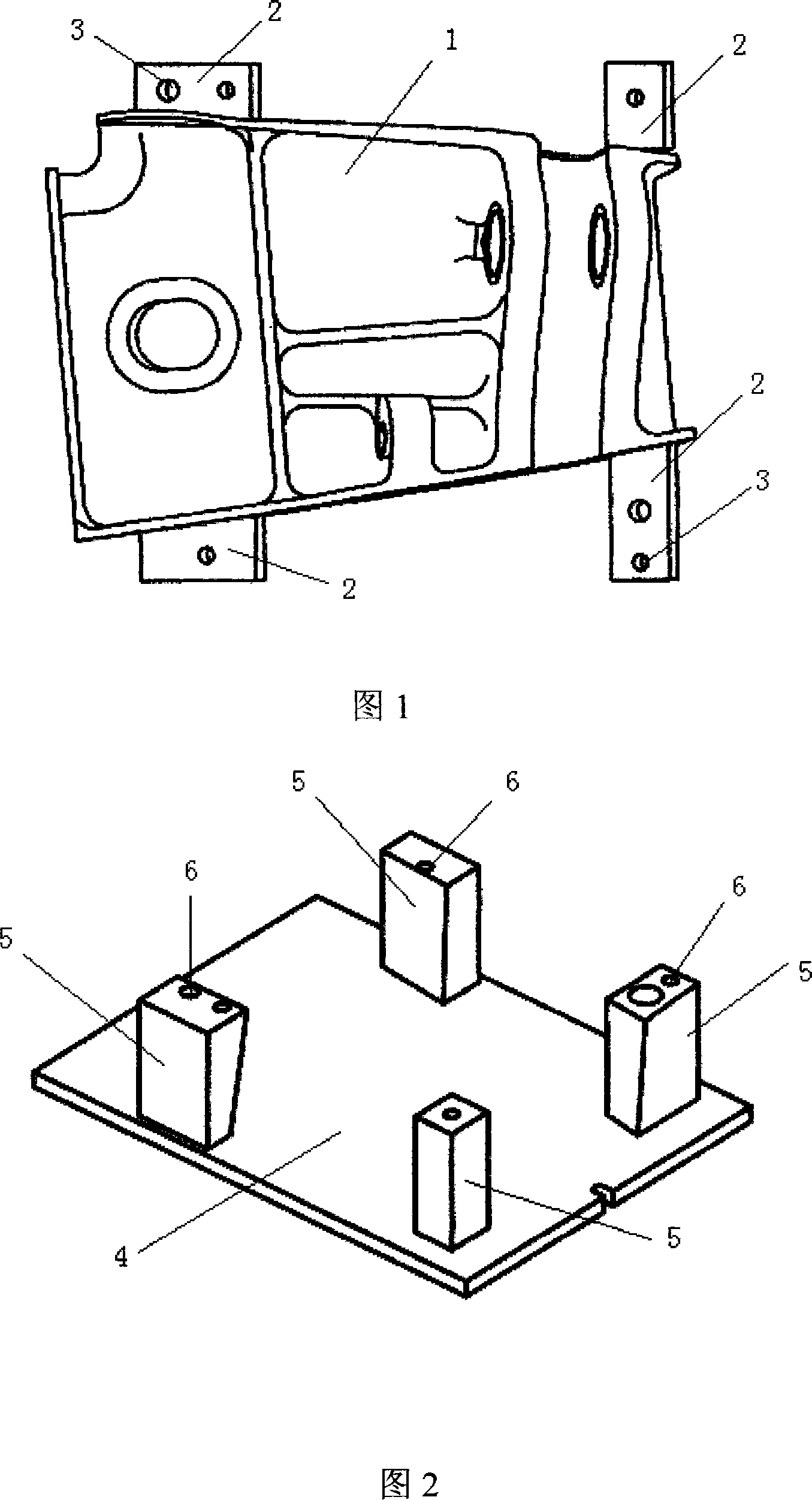

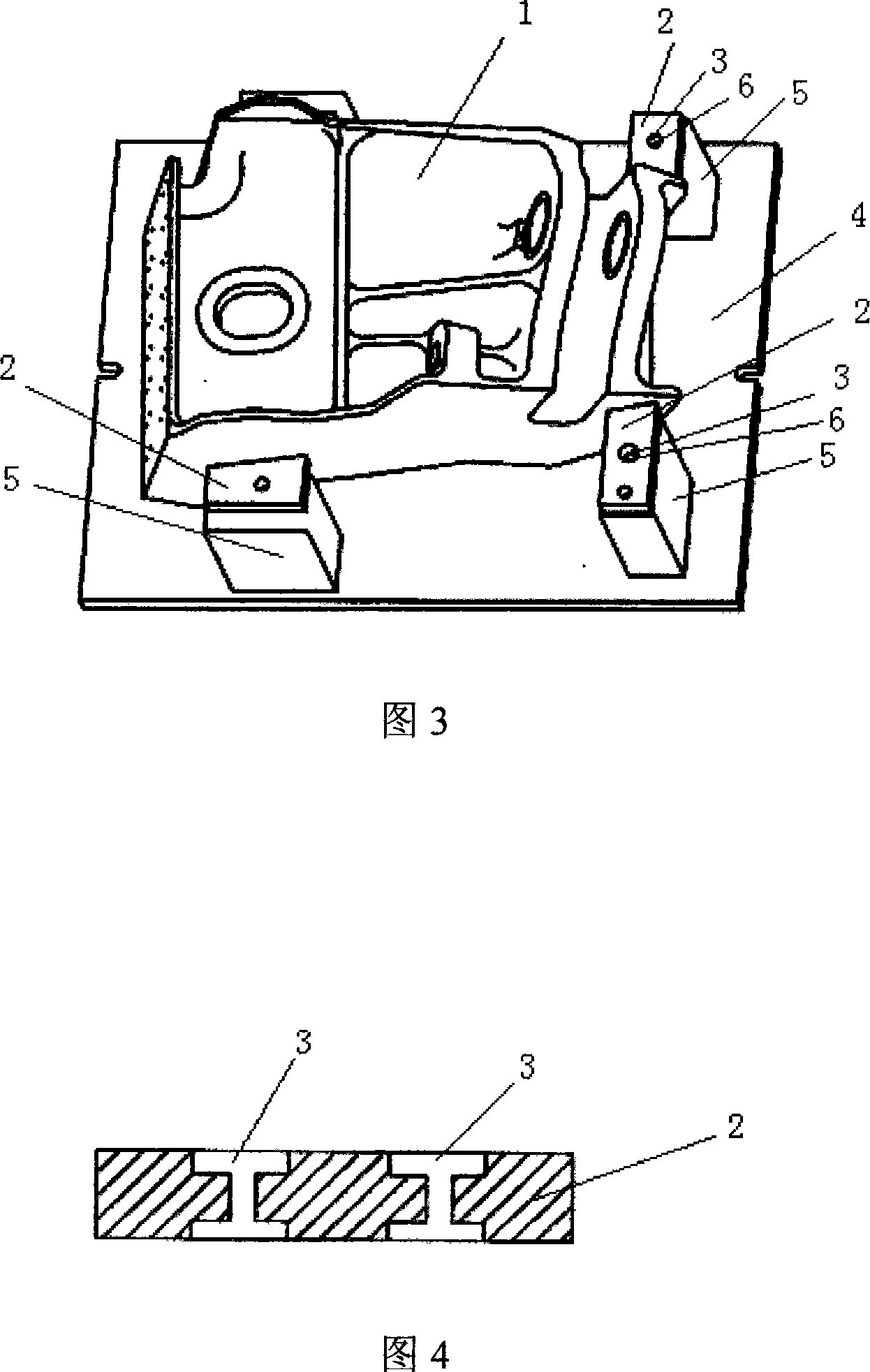

[0014] The joint part 1 shown in FIG. 1 is a complex box-shaped structure, and four process positioning tables 2 are arranged on the theoretical shape of both sides of the part (the process positioning tables are removed after the part is processed). Each process positioning table is provided with a connection positioning hole 3. In practice, the connection positioning hole 3 is an inner hexagonal bolt hole, as shown in FIG. 4, so that the connection bolt is not higher than the surface of the process positioning table. The milling tool of FIG. 2 includes a milling body 4 and four support blocks 5. The milling body 4 is a stable plate-like structure, and the support block 5 is a columnar structure with a support surface. The support blocks are respectively fixed on the periphery of the milling body’s flat plate structure. Position, the connection between the support block and the milling unit is fixed by socket head cap screws and open washers. The support surface of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com