Tyre with integral curtain cloth reinforced layer

A carcass ply and reinforcing layer technology, which is applied in tire parts, reinforcing layers of pneumatic tires, transportation and packaging, etc., can solve the problems of inconsistent positions, inconsistencies, displacement of ply reinforcing layers, etc., to reduce foaming, The effect of increasing the impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

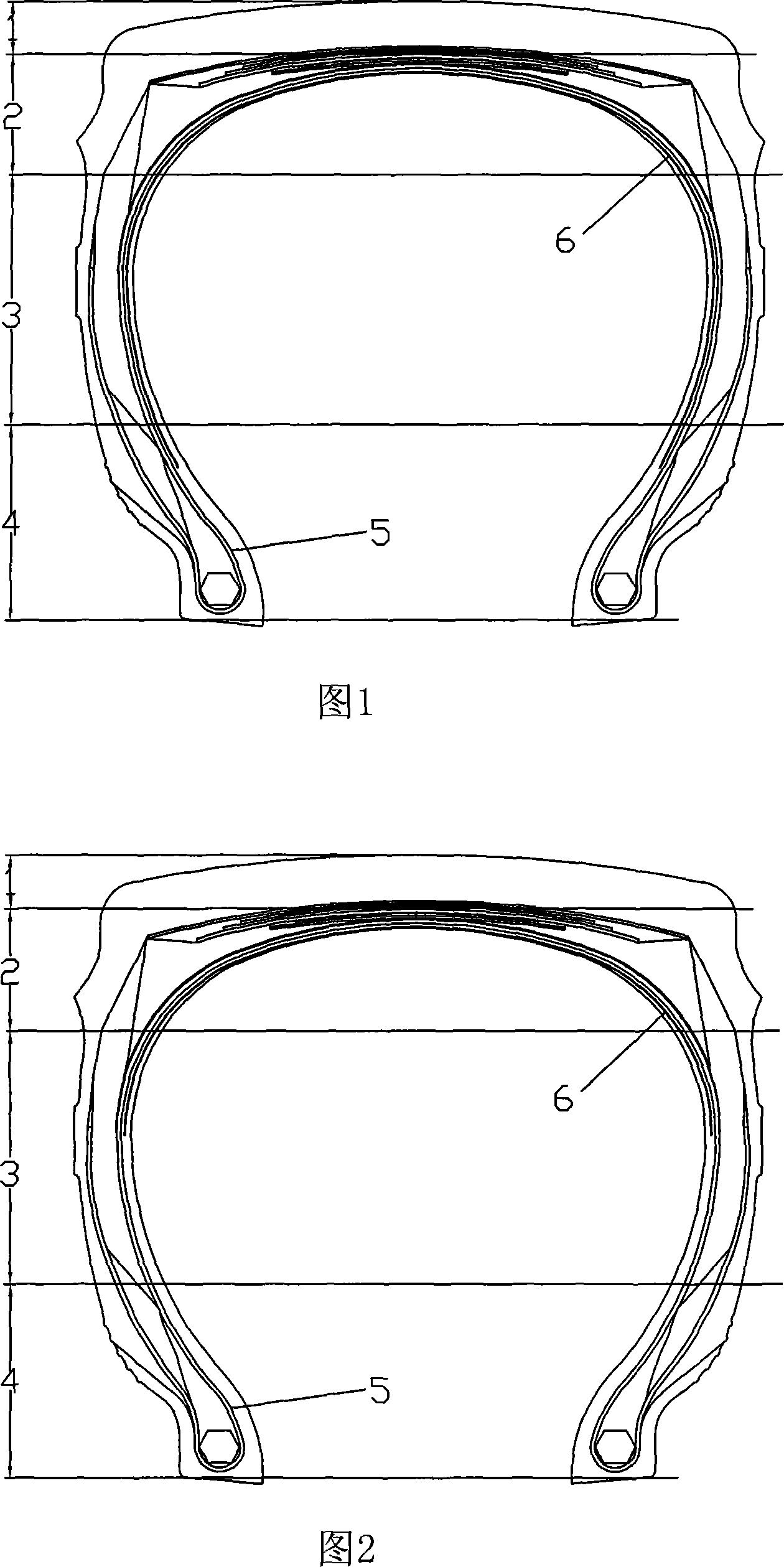

[0016] In the embodiment shown in Fig. 1, the tire with integral ply reinforcement of the present invention includes a carcass, and the carcass is divided into a crown area 4, a shoulder area 3, a sidewall flexing area 2 and a bead area 1; There is a carcass ply 5 in the body, and the radial inner side of the carcass ply 5 extends from the bead area 1 on the side of the carcass across the sidewall flexing area 2, the shoulder area 3 and the crown area 4 to the tire tire. The bead area 1 on the other side of the body is provided with a nylon ply reinforcing layer 6 of an integral structure.

Embodiment 2

[0018] In the embodiment shown in Fig. 2, the tire with integral ply reinforcement of the present invention includes a carcass, and the carcass is divided into a crown area 4, a shoulder area 3, a sidewall flexing area 2 and a bead area 1; There is a carcass ply 5 in the body, and the radial inner side of the carcass ply 5 extends from the sidewall flex zone 2 on one side of the carcass across the shoulder zone 3 and the crown zone 4 to the sidewall on the other side of the carcass. The flexing zone 2 is provided with a nylon cord reinforcing layer 6 of an integral structure.

Embodiment 3

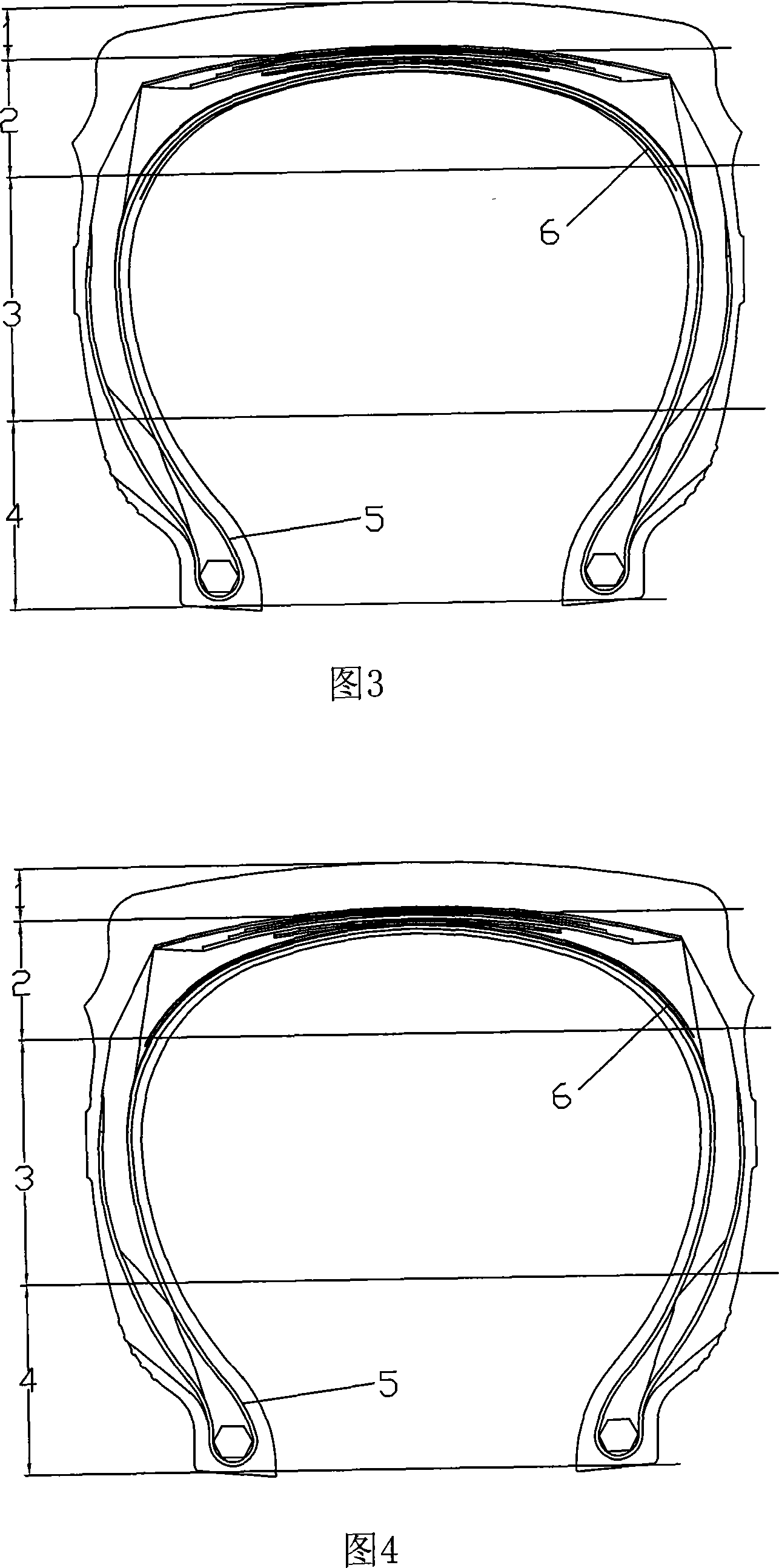

[0020] In the embodiment shown in Fig. 3, the tire with integral ply reinforcement of the present invention includes a carcass, and the carcass is divided into a crown area 4, a shoulder area 3, a sidewall flexing area 2 and a bead area 1; There is a carcass ply 5 in the body, and the radial inner side of the carcass ply 5 extends from the shoulder area 3 on one side of the carcass across the crown area 4 to the shoulder area 3 on the other side of the carcass. Nylon ply reinforcement 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com