Technique for semi-continuously producing light metal and producing device thereof

A production process and light metal technology, applied in the field of semi-continuous production of light metal production process and its production equipment, can solve problems such as heat loss, achieve the effect of increasing daily production capacity, significant economic benefits, and reducing the time for heating raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

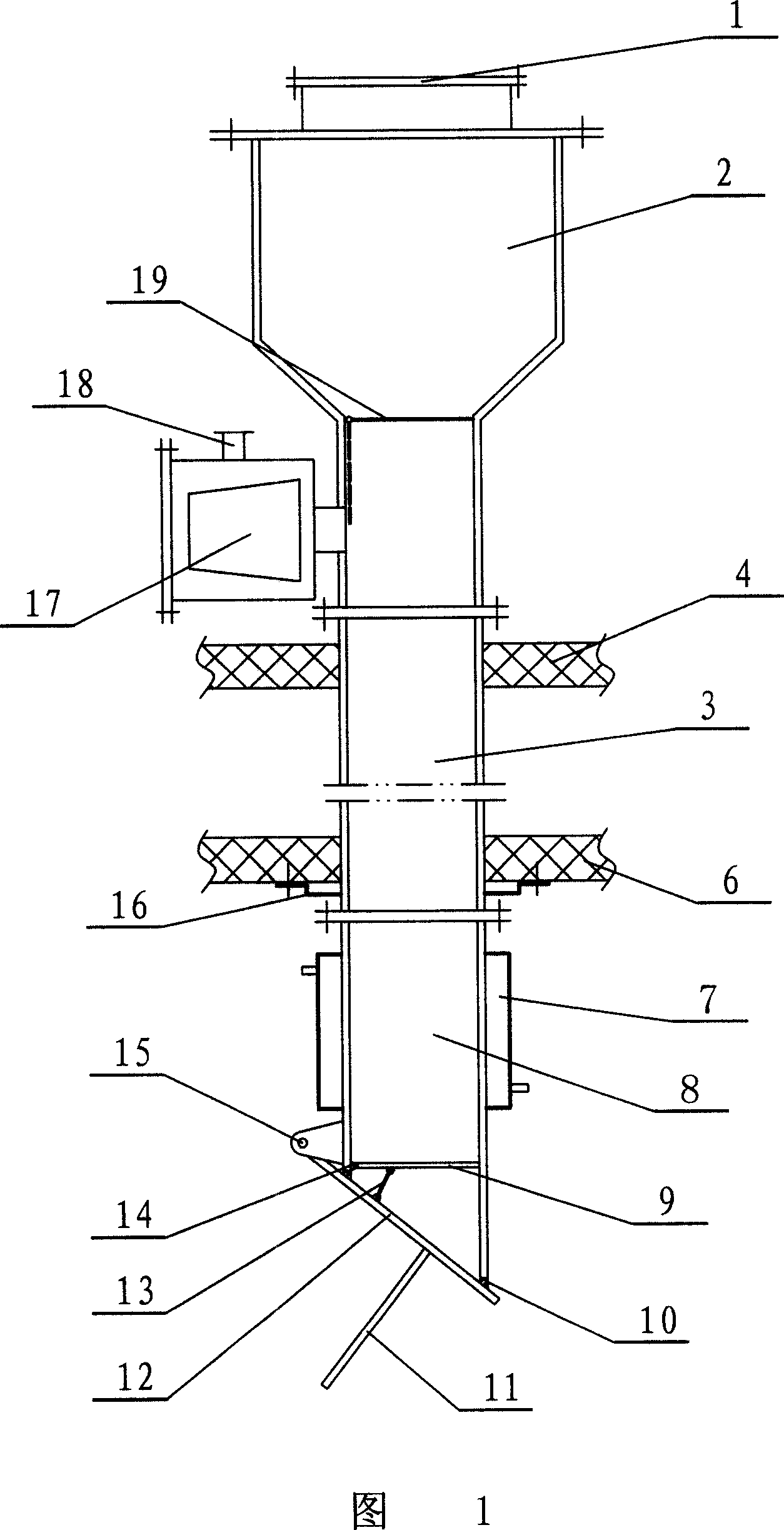

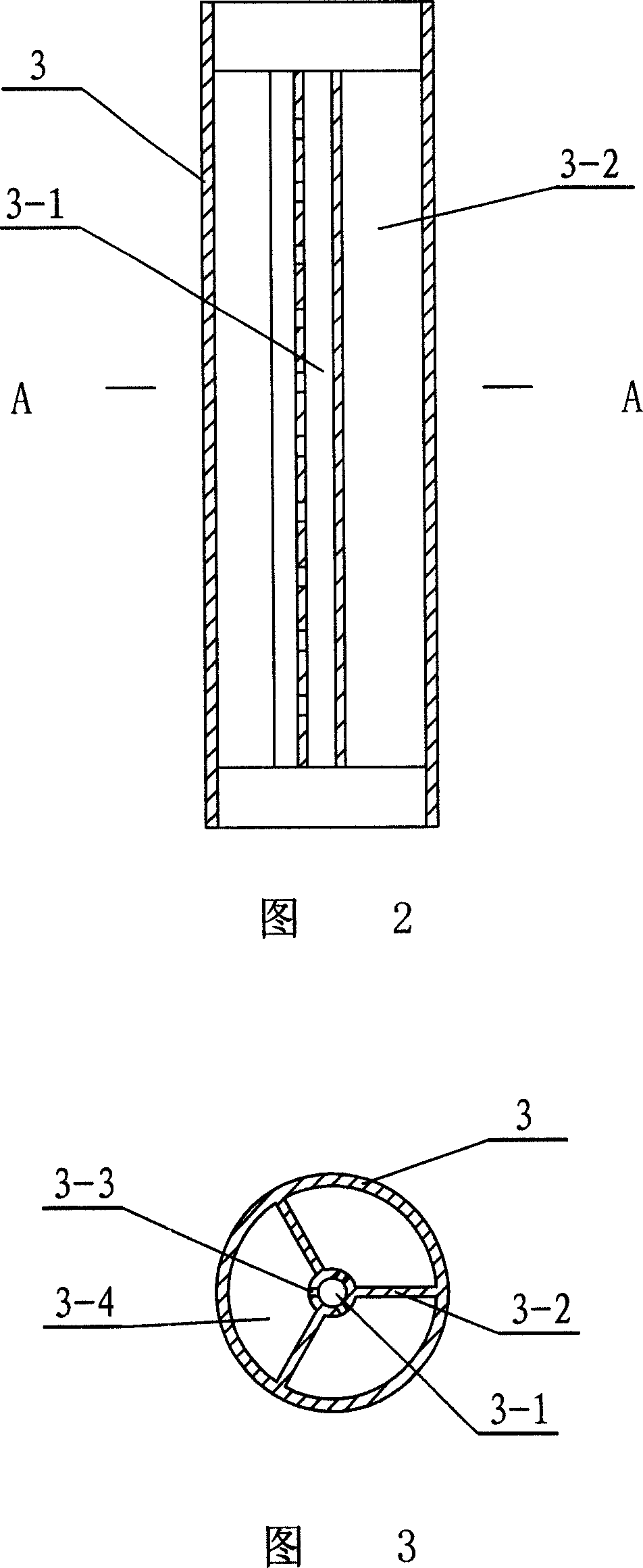

[0019] This embodiment takes the production of magnesium metal as an example for illustration. As shown in Figure 1, the upper and lower parts of the reduction tank 3 vertically installed in the heating furnace protrude from the furnace roof 4 and the furnace bottom 6 of the heating furnace respectively, and the middle part of the reduction tank is heated in the heating furnace. A preheating storage bin 2 is installed at the upper end of the reduction tank 3, and the outlet of the preheating storage bin is sealed and fixedly connected with the upper end of the reduction tank 3, and the gap between the preheating storage bin 2 and the furnace roof 4 is A metal magnesium crystallizer 17 is fixedly installed on the reduction tank, and a connection port 18 connected with vacuum equipment is fixed on the metal magnesium crystallizer 17 . The outside of the protruding part of the lower end of the reduction tank 3 is fixedly equipped with a support frame 16, and the reduction tank is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com