Vertical axis type drilling machine inclined hole boring machine

A vertical shaft type, drilling machine technology, applied in drilling equipment, directional drilling, earthwork drilling, etc., can solve the problems of drilling construction safety and drilling efficiency decline, affecting the mechanical performance of the drilling tower, and high labor intensity. , to achieve the effect of increasing the scope of use, rapid equipment installation and relocation, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

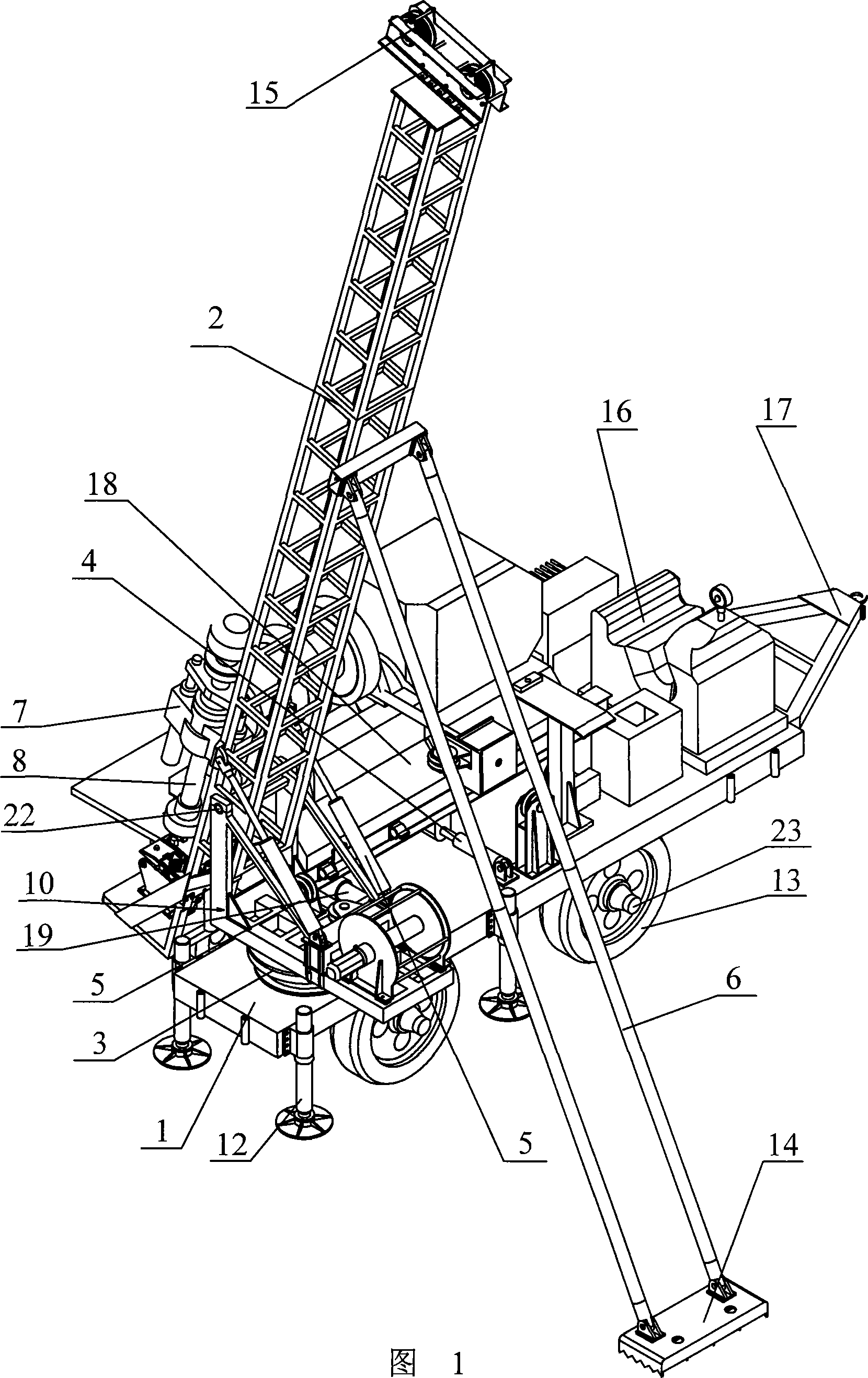

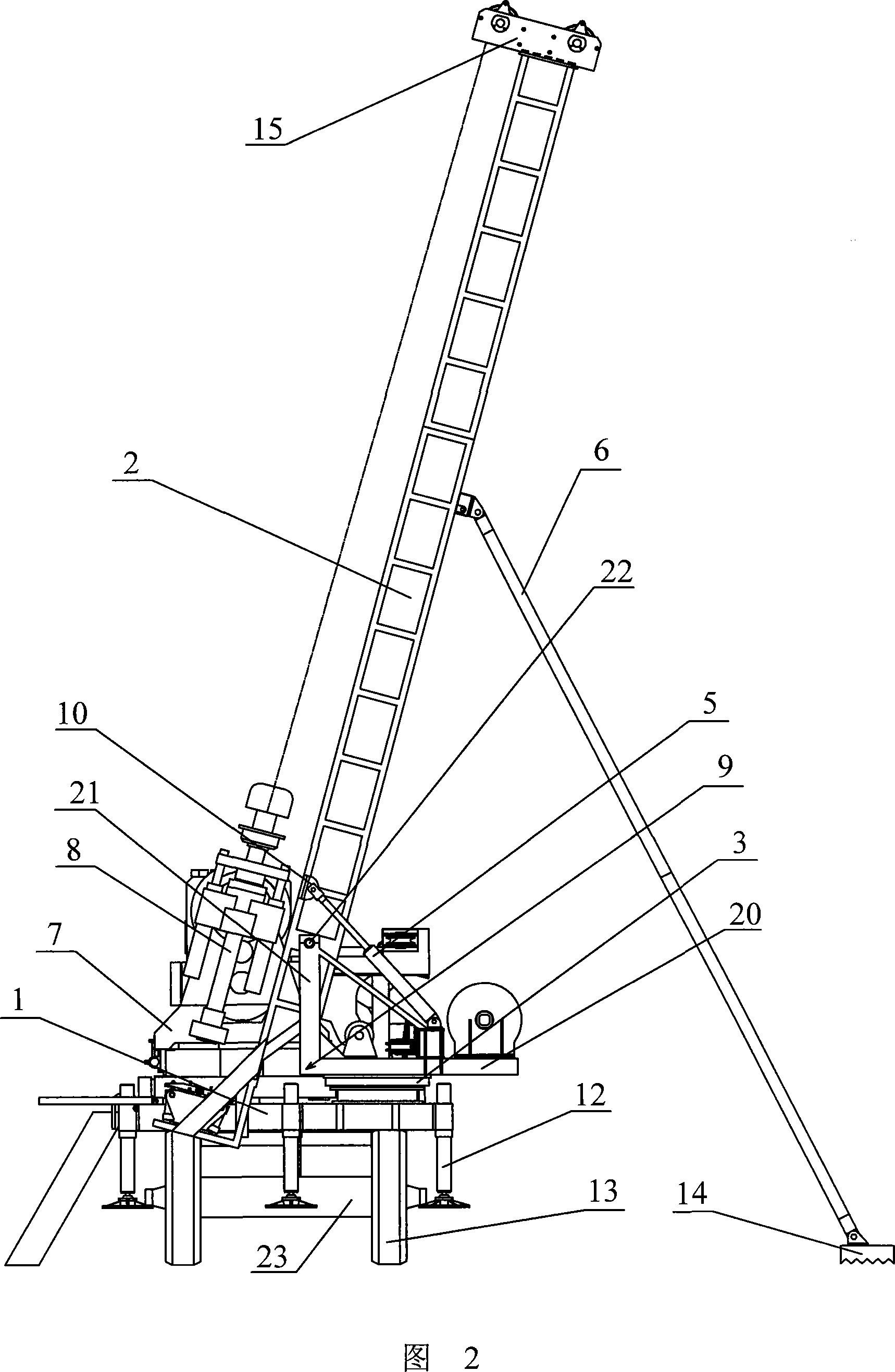

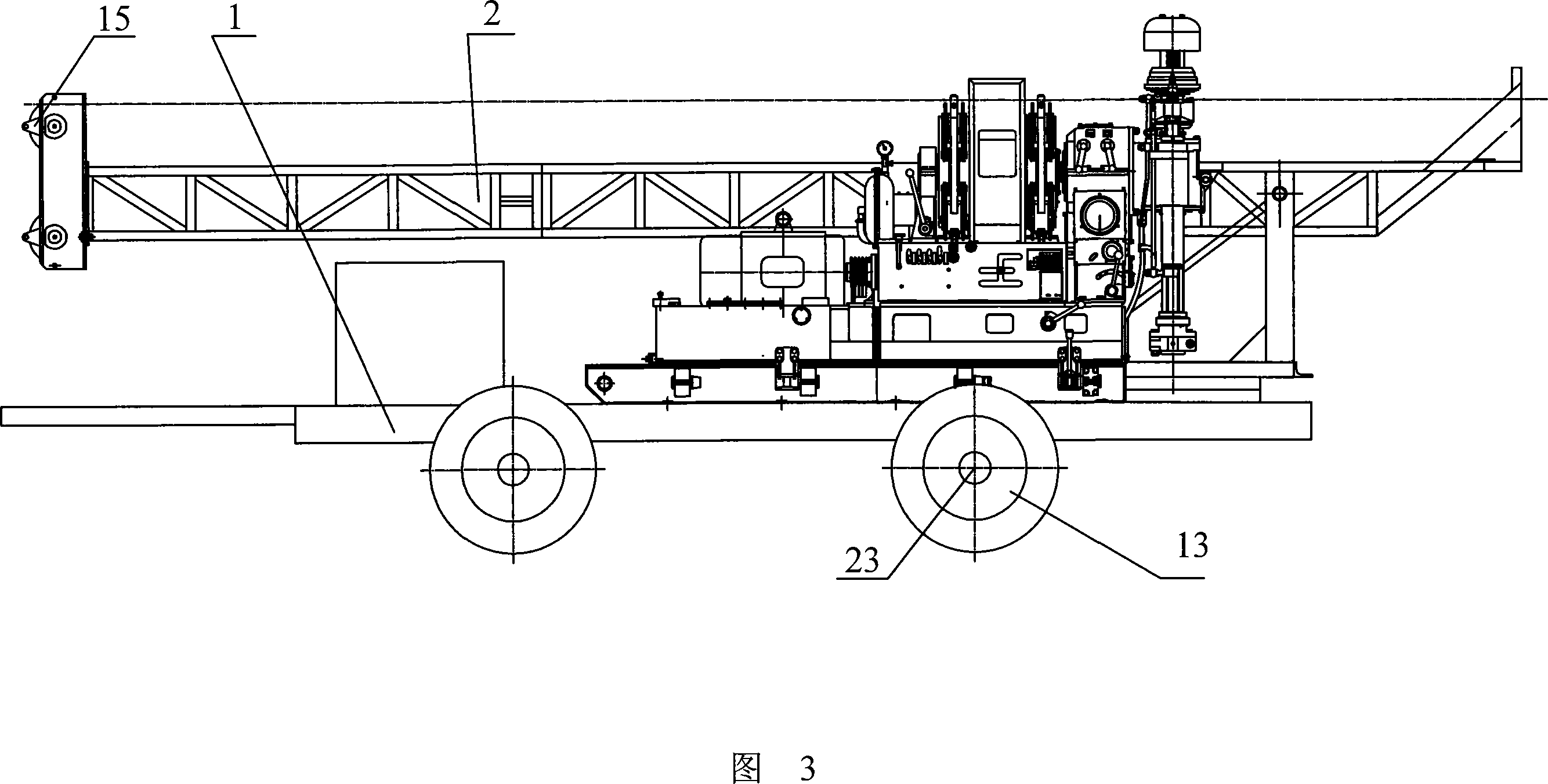

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] As shown in the figure: the vertical shaft drilling machine inclined hole drilling machine of the present invention is provided with a slewing support 3 on the chassis 1, a drilling tower body support 9 is provided on the slewing support 3, and a drill is hinged on the drilling tower body support 9. The tower body 2 is provided with a drilling rig body 7 and its output rotary spindle 8 on the drilling tower body 2 , and an angle adjustment mechanism of the drilling tower body 2 is connected between the drilling tower body support 9 and the drilling tower body 2 .

[0014] The angle adjustment mechanism is a pair of lifting oil cylinders 5 arranged on the drilling tower body support 9. The bottom end of the cylinder block of the lifting tower oil cylinder 5 is connected on the drilling tower body support 9, and the top end of its piston rod is hinged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com