Motorcycle engine vibration damping device

A vibration damping mechanism and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as failure to reduce vibration, inability to install crankcases, and increase in cost, and improve output power and torque, The effect of improving user comfort and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments:

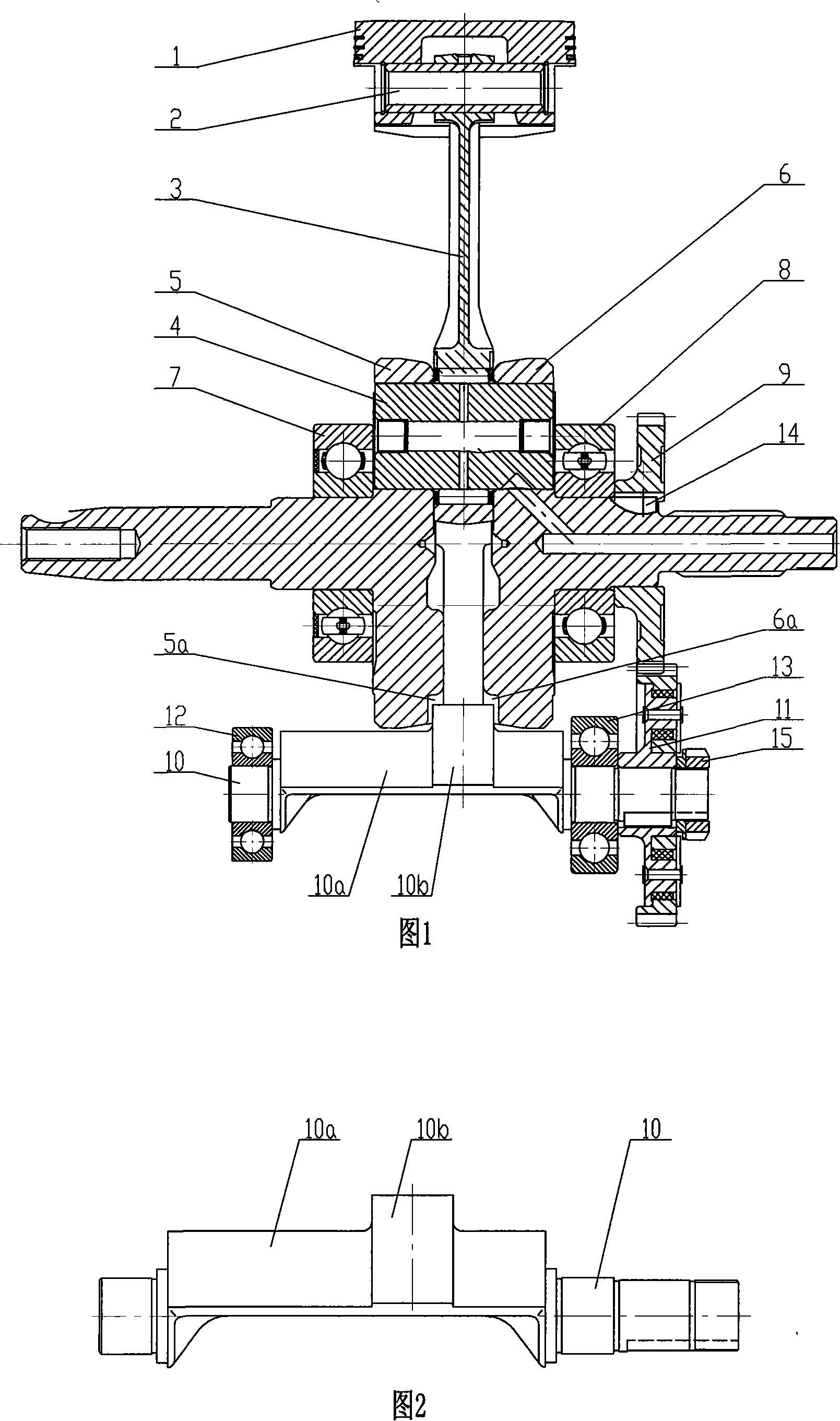

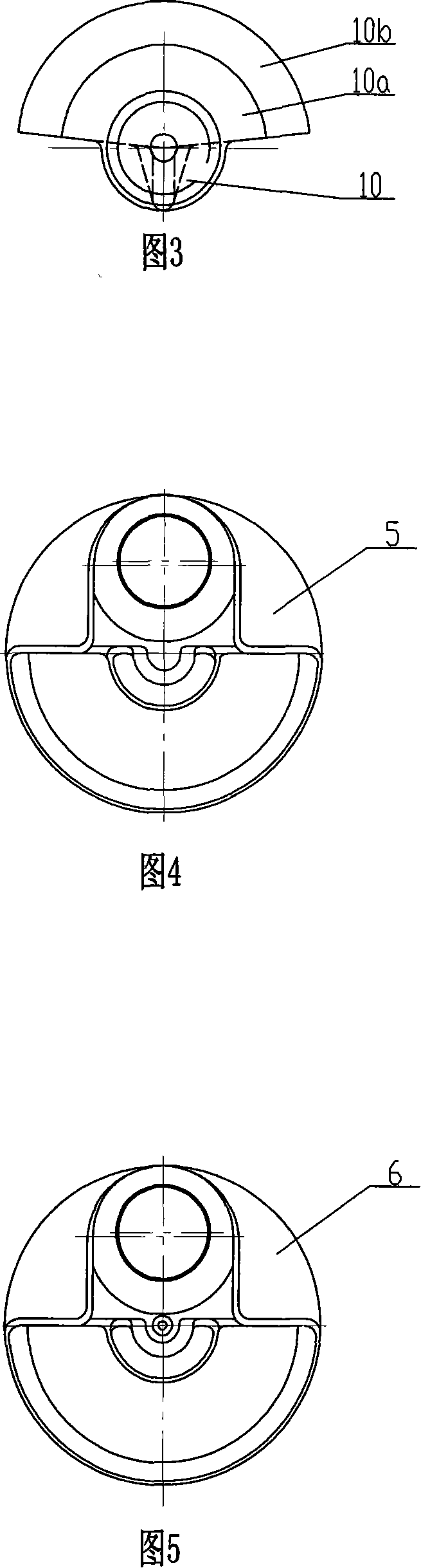

[0018] As shown in Fig. 1, Fig. 4 and Fig. 5, in order to reduce the weight of the piston 1 and reduce the reciprocating inertia force during the operation of the crank connecting rod mechanism, the cross section of the piston 1 along its axis is "T" shaped. The piston 1 is connected with the small end of the connecting rod 3 through the piston pin 2, and the large end of the connecting rod 3 is installed between the symmetrically arranged left and right cranks 5 and 6 through the crank pin 4. The opposite surfaces of the left and right cranks 5 and 6 are symmetrically provided with notches 5a, 6a, wherein the notches 5a on the left crank 5 are arc-shaped, distributed along the edge of the lower half of the left crank 5 (see Figure 1 and Figure 4); the notches 6a on the right crank 6 are also arc-shaped, distributed along the edge of the lower half of the handle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com