Method for repairing light mask image

A photomask and graphics technology, which is applied to the photoplate-making process of the pattern surface, the original for photomechanical processing, optics, etc., can solve the problems of increased cost of the photomask, unusable photomask, inaccurate positioning, etc., to achieve Increased repair probability, reduced production costs, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

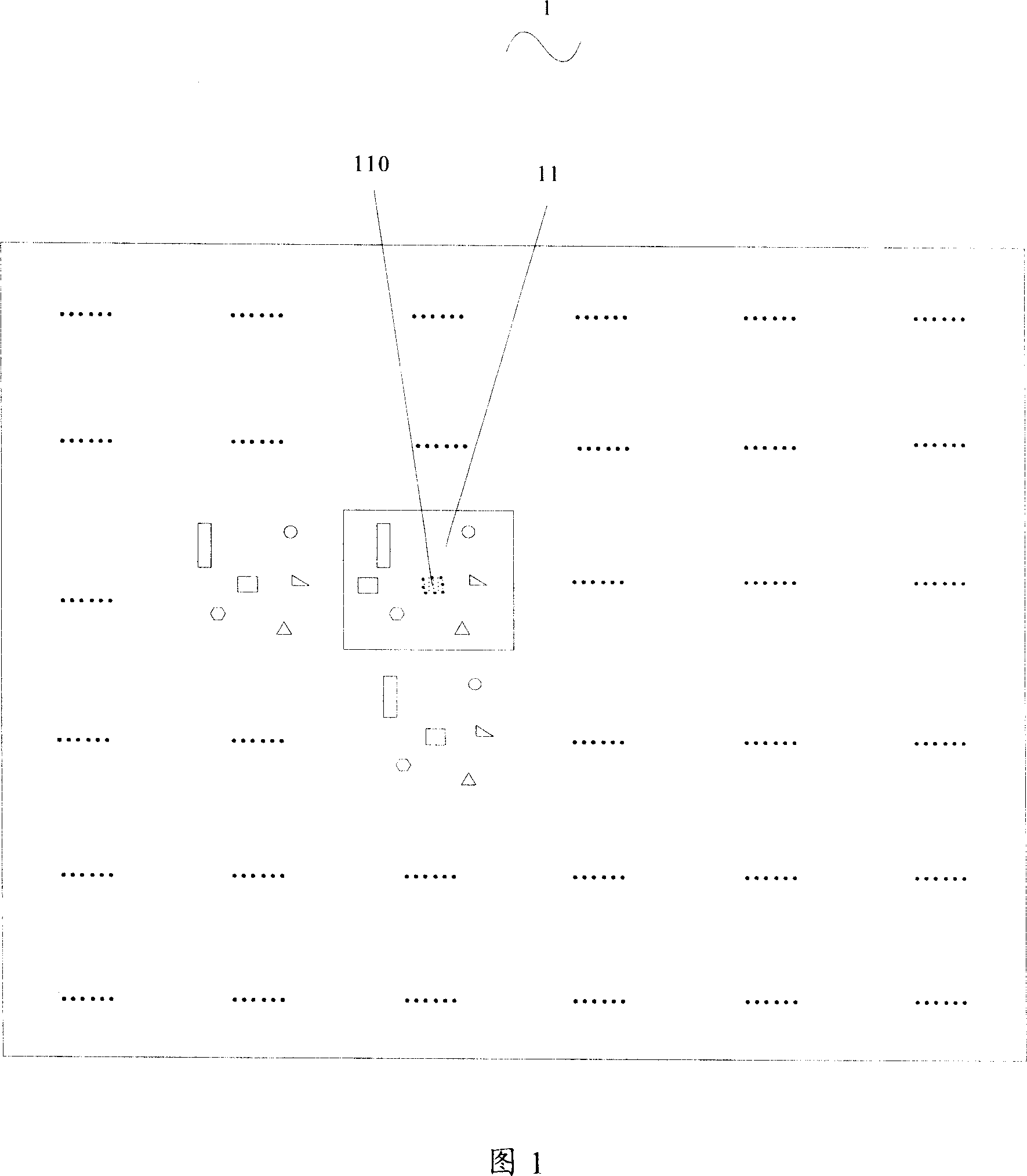

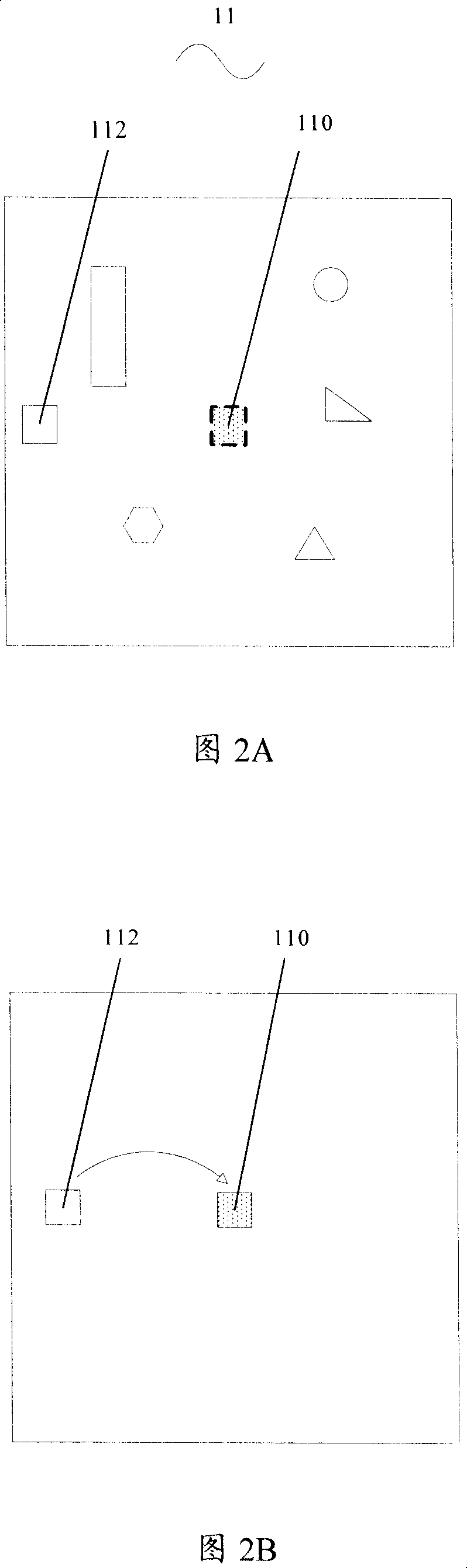

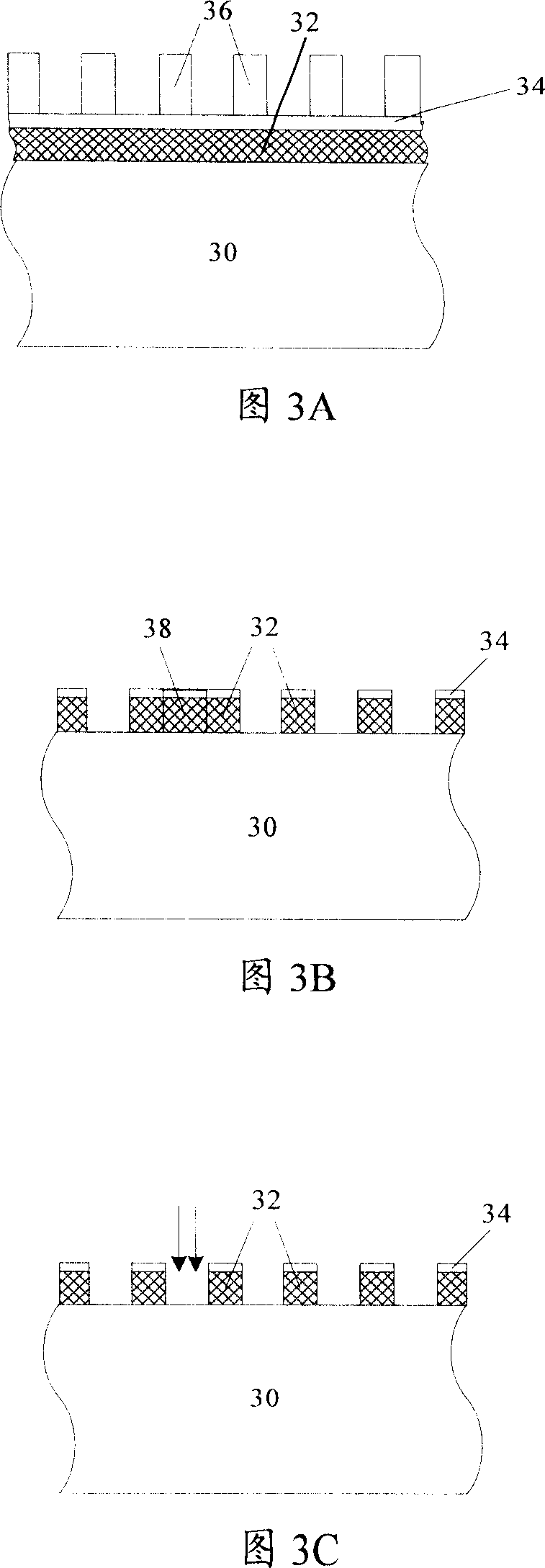

[0031] During the production process of the photomask, because the photomask is contaminated with a little particle in the environment, the uneven exposure energy or the problem of the resist material are easy to produce defect patterns. In the prior art, the positioning is not accurate when repairing the defect pattern, and because no suitable defect-free pattern can not be found within the window range as a reference pattern to repair the defect pattern, the fabricated photomask is unusable and must be remade, causing the photomask Increased costs. The invention repairs the defective pattern on the photomask by enlarging the range of finding the non-defective pattern with the same shape and size as the defective pattern and gradually outputting the reference pattern to the direction of the defective pattern by the repairing instrument. The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com