Ear inserting comb-stripping machine

A technology for combing off and cutting ears, which is applied in the field of high-efficiency cutting and combing offline, can solve the problems of many broken ears and poor performance at low speed, and achieves the uniformity of ear heads and rows. , the effect of less ear breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

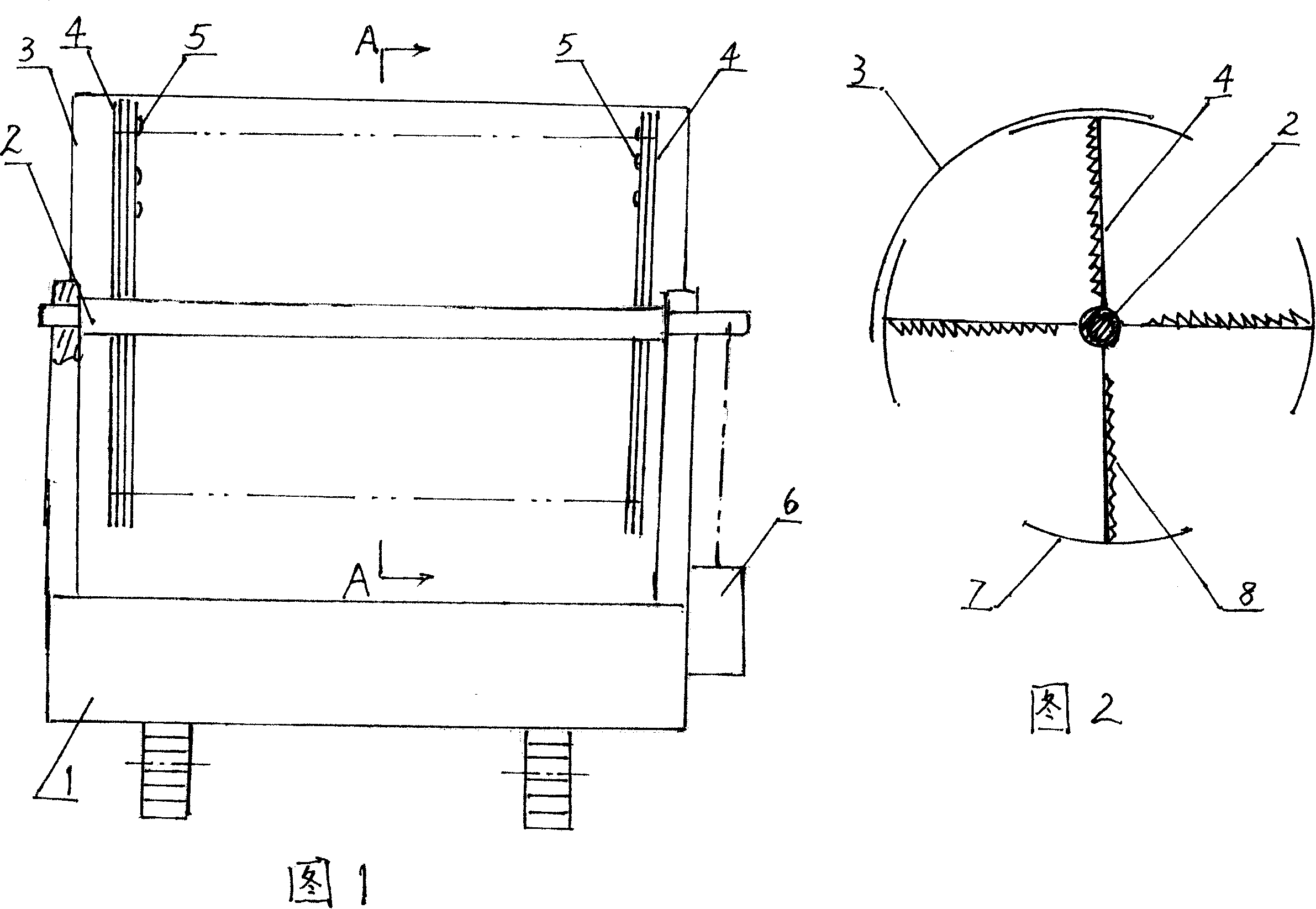

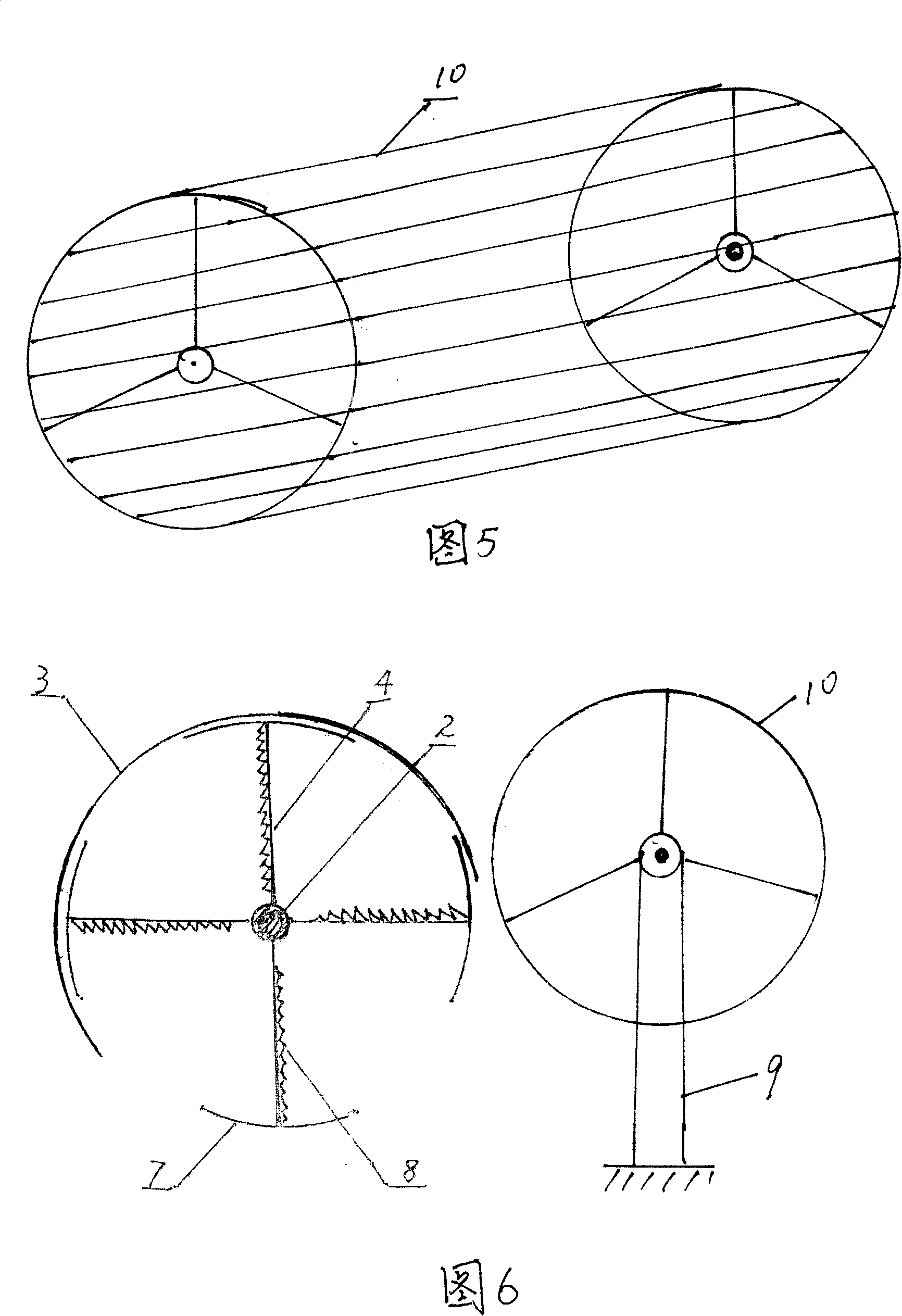

[0021] Example 1: referring to Fig. 1, Fig. 2, one of structure of the present invention, it has the basic structure of common comb threshing machine, mainly by walking frame 1, combing device that is contained on the walking frame 1, transmission device 6 And comb off cover 3 to form. Especially the improvements in the present invention, its combing device is quite different from the prior art, it has a rotating shaft 2, four rows (at least one row gets final product) are welded on the rotating shaft 2 and one end extends outwards The elongated comb takes off the teeth 4 (can adopt No. 8 steel wire to make), and the spacing of the combs takes off the teeth is 2.5mm. In order to facilitate combing off the rice grains at the bottom of the ears of grain, in the present invention, three small protrusions 5 are formed on the two side walls of the ears of grain held by the combing teeth 2, and sawtooths are formed on the upper surface of the combing teeth 2. 8. In addition, an ar...

example 2

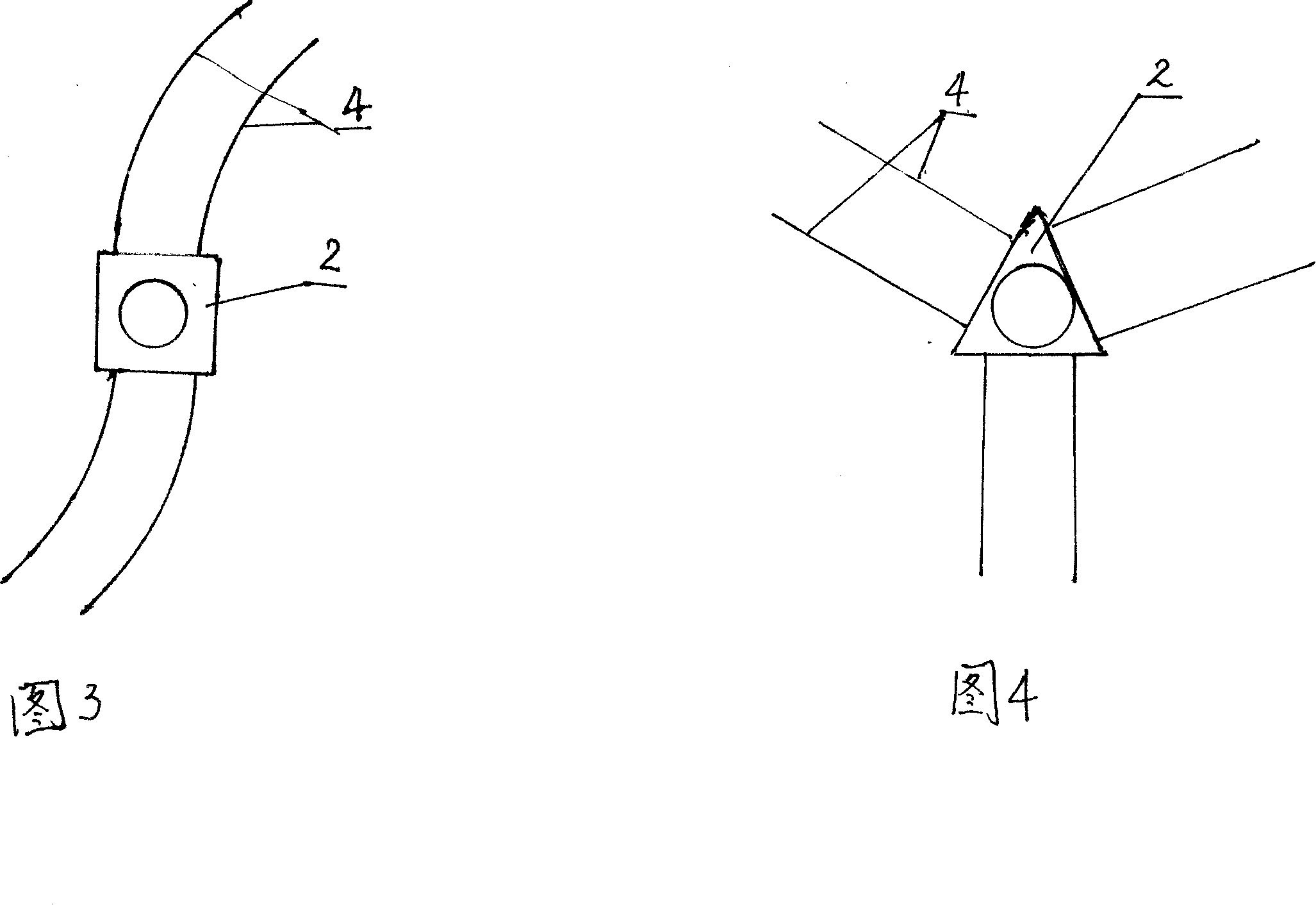

[0022] Example 2: the second structure of the present invention is basically the same as the example 1 structure, and the difference is that the rotating shaft 2 section of the combing device is square, and two rows of one end are respectively welded on two opposite sides of the rotating shaft 2 to extend outwards. The elongated comb takes off the teeth 4 (can adopt No. 10 steel wire to make), and the spacing of the combs takes off the teeth in each row can be arranged by 3.5mm, and the combs take off the teeth and bend to make an arc shape better, see Fig. 3.

example 3

[0023] Example 3: structure three of the present invention, basically the same example 1 structure, difference is: the rotating shaft 2 cross-sections of its combing device are triangular, on three planes of the triangular rotating shaft 2 (also can be on 1-2 planes ) Each welding is equipped with two rows of strip-shaped comb strips 4 (can adopt No. 10 steel wire to make) that one end extends outwards, and the spacing of the comb strips in each row can be arranged by 5mm, see Fig. 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com