Air-float filter pool

An air flotation filter and air flotation technology, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of uneven water distribution, manual cleaning, and the depth of the air flotation pool, so as to improve the effective filtration area and simplify the Production management process, optimize the effect of water purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

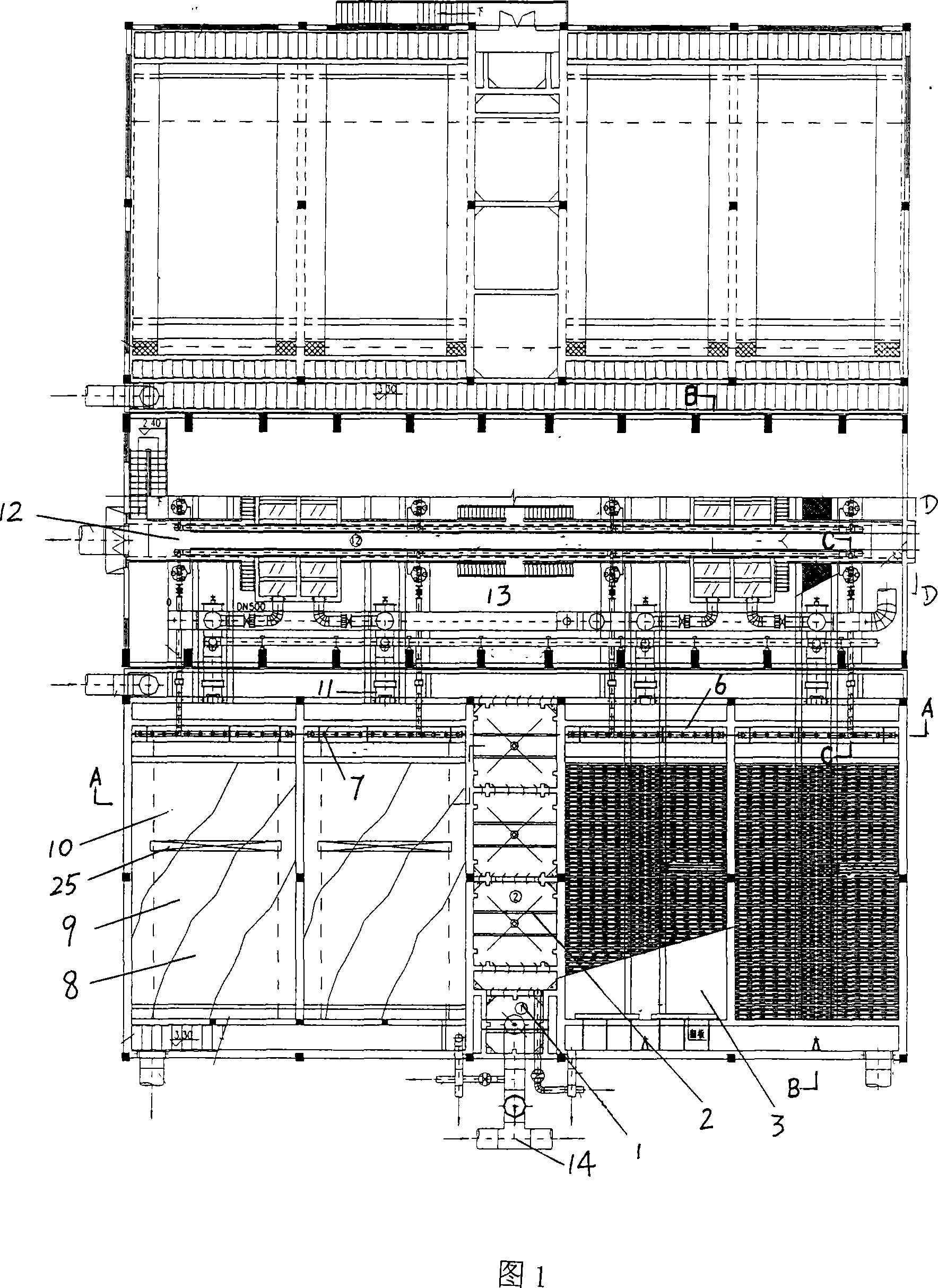

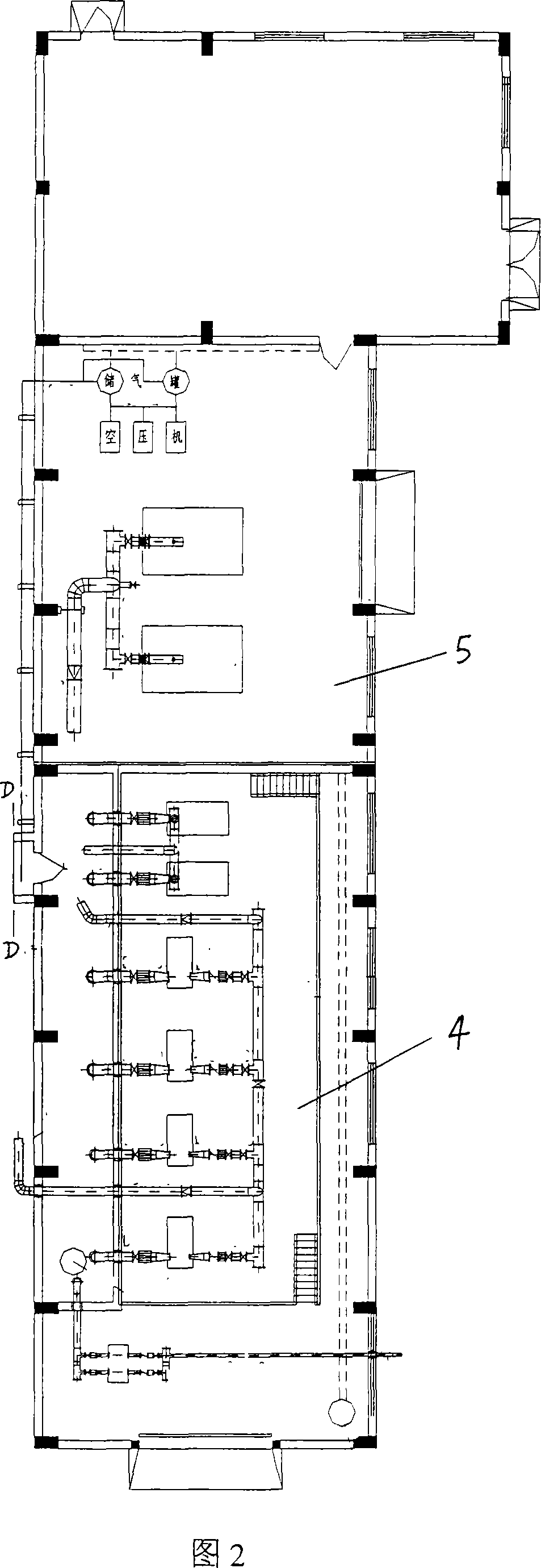

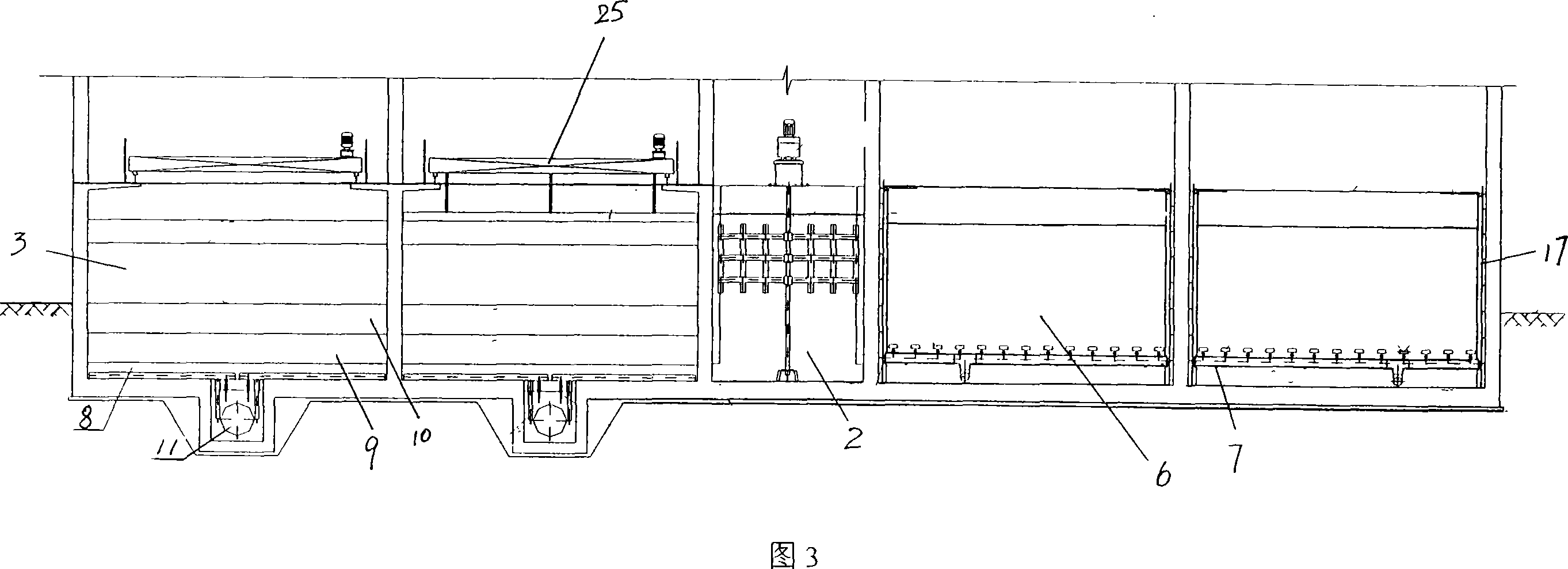

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] The embodiment shown in the figure is a design scale of 120,000 m 3 The / d air flotation filter has a total of 8 grid flap filter tanks 3, arranged in double rows, with 4 grids in each row. A mechanical mixing tank 1 and a group of mechanical flocculation tanks 2 are arranged in the middle of each row of filters, and a comprehensive pump room 4 and blower room 5 are arranged on the side of the flap filter 3. The single filter area of the flap filter 3 is 100m 2 , 12.5m long and 8m wide. The filtered water is used as air flotation dissolved air water, and the reflux ratio is adjustable within the range of 5% to 10%. The design ascending velocity of the air flotation tank is 2mm / s, and the design filtration velocity of the filter is 7.2m / h. Figure 2 and Figure 1 are connected at the D-D line.

[0020] The air flotation filter is superimpose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com