Towel automatic sorter

An automatic sorting and towel technology, which is applied in the direction of pile separation, object separation, and object supply, can solve problems such as automatic towel sorting, towel fluff sticking to each other, and increased labor costs, so as to achieve a wide range of applications and avoid secondary problems. Secondary pollution, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

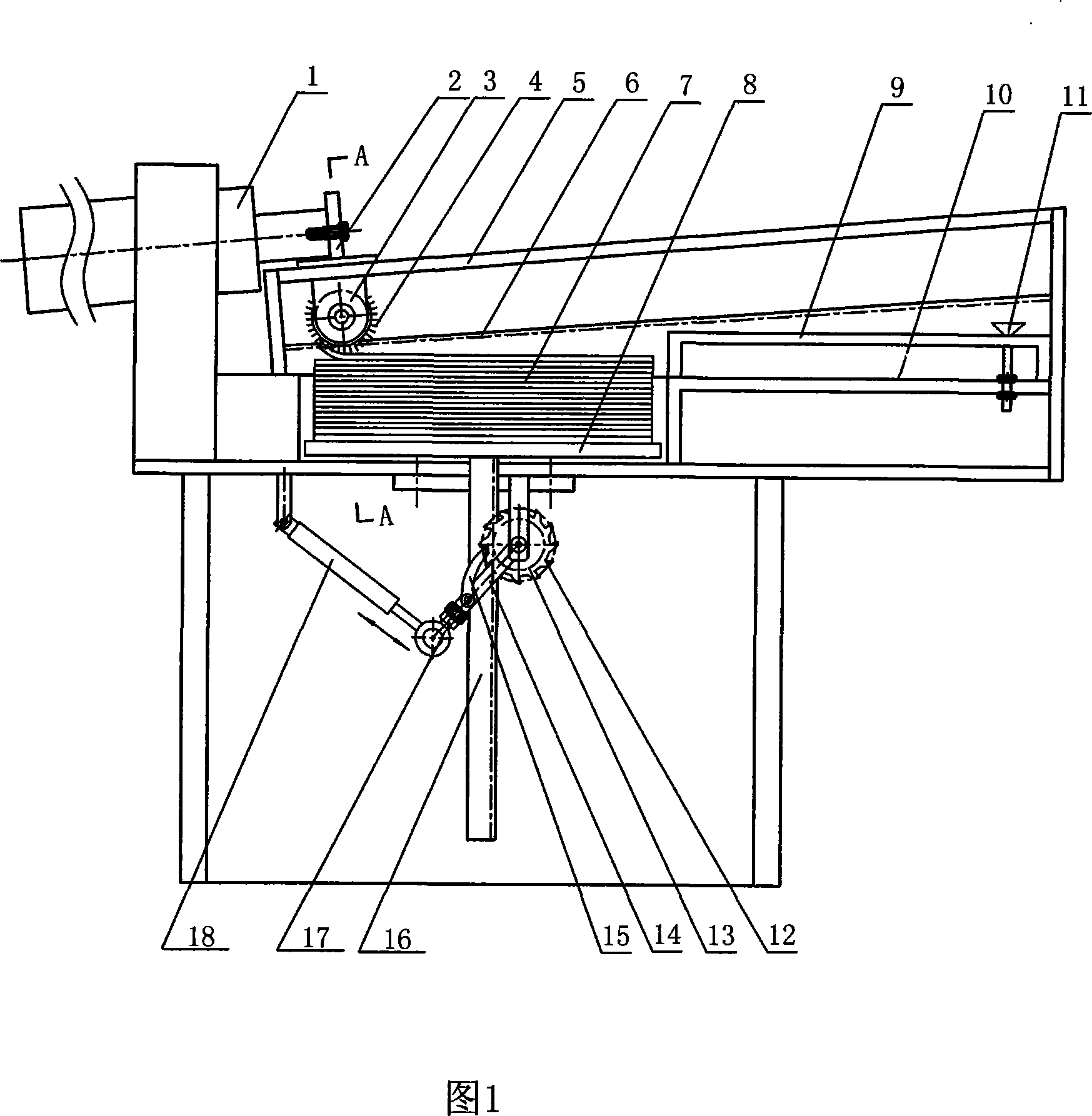

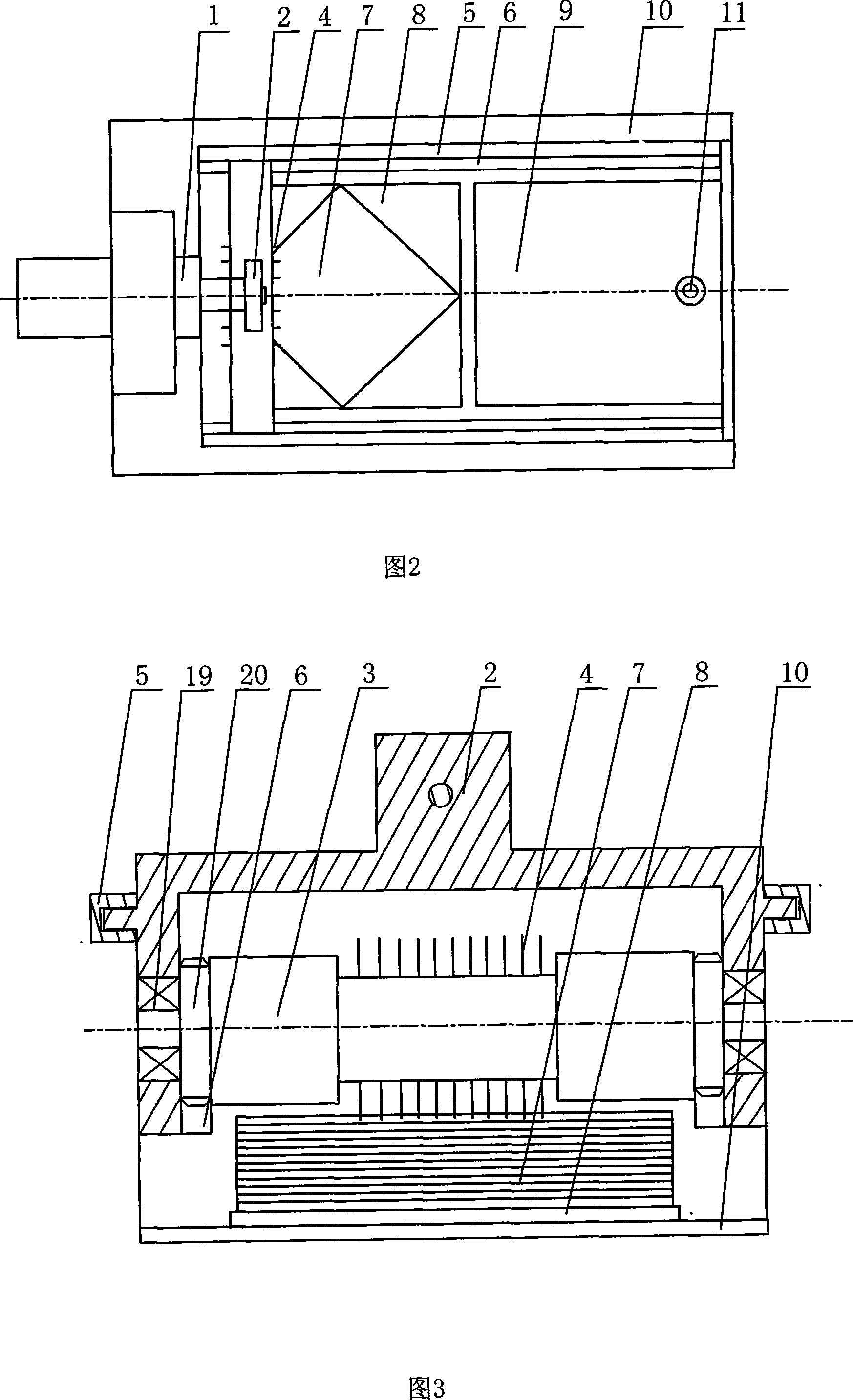

[0022] The towel automatic sorter has an overall structure consisting of a frame 10, a winding mechanism, a feeding mechanism, and a receiving tray 9, wherein:

[0023] winding mechanism

[0024] The winding mechanism is installed above the frame and consists of winding cylinder 1, transverse guide rail 5, transverse rack 6, licker-in roller 3 and licker-in roller frame 2. The horizontal guide rails and the horizontal racks of the winding mechanism are a pair of parallel ones and are installed on the machine frame with an upward inclination. , the inclination angle between it and the horizontal plane is 3-15°, in this embodiment, the inclination angle of its installation is 5°, of course, it can also be installed at any angle between 3-15°. The licker-in roller frame is installed on the transverse guide rail, and the top of the licker-in roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com