Power battery testing and sorting method

A power electric and sorting technology, which is applied in sorting and other directions, can solve the problems of mixed storage, many internal resistance meters, equipment investment cost and low cost performance of production capacity, and achieve the effect of preventing dumping and good position limiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

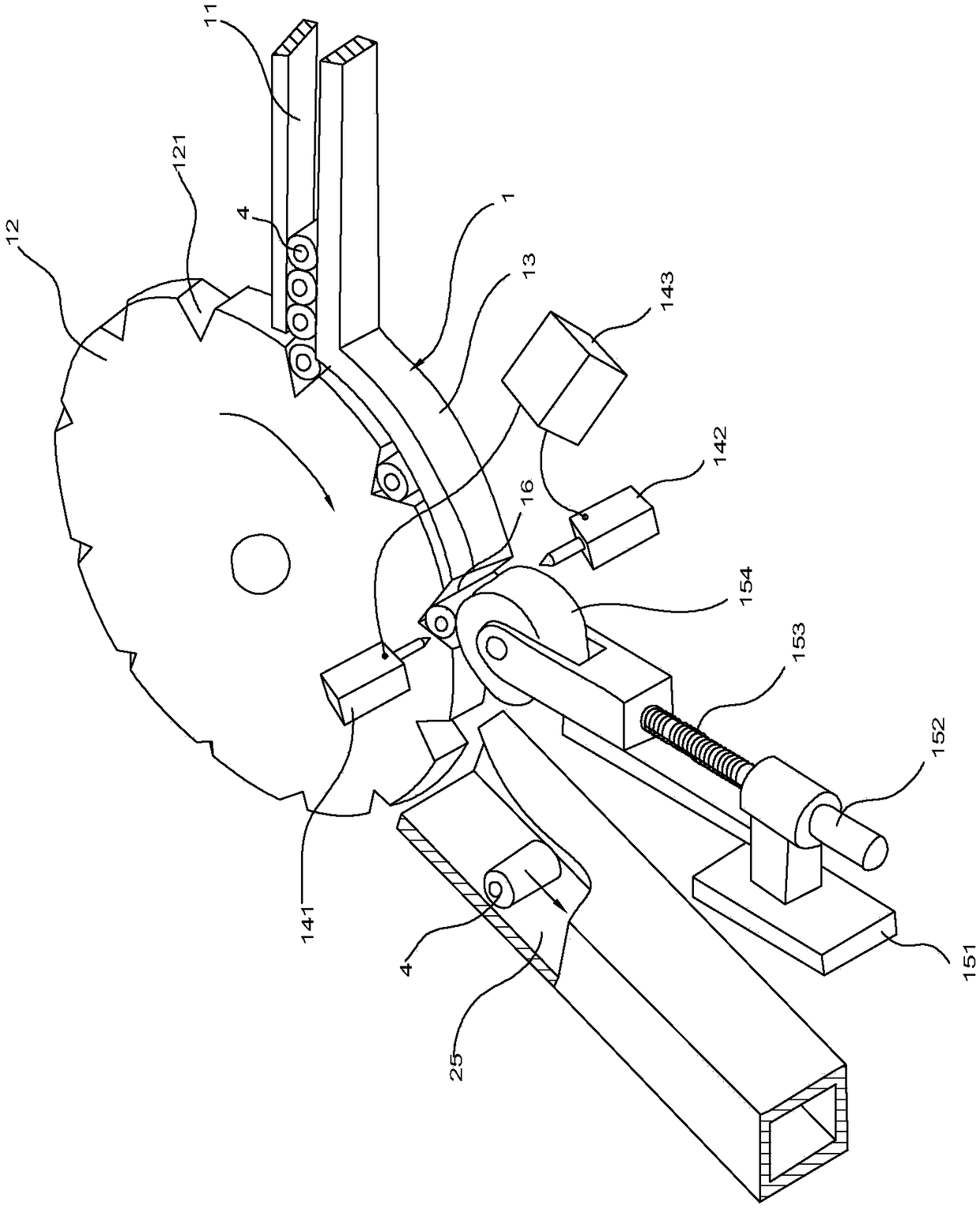

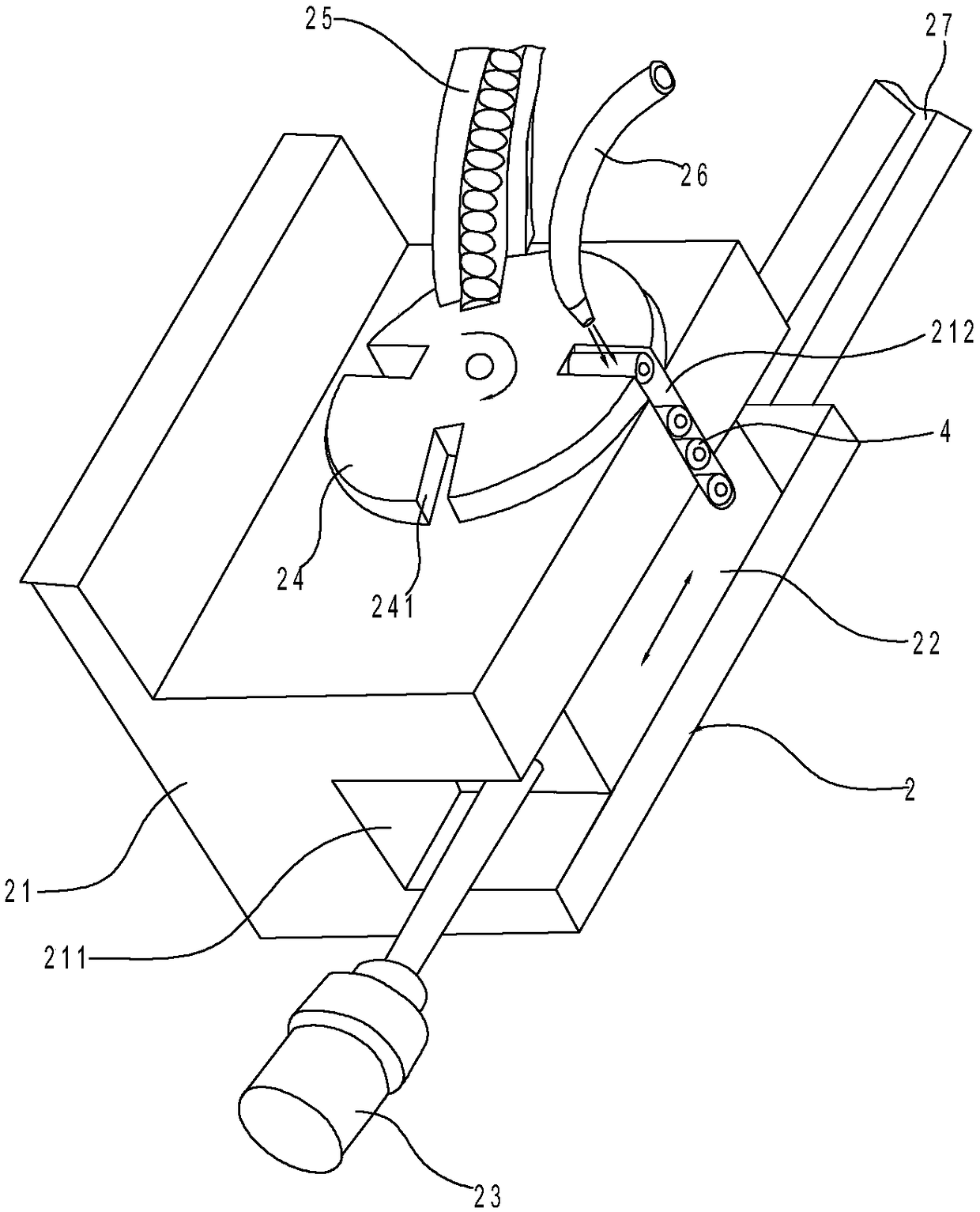

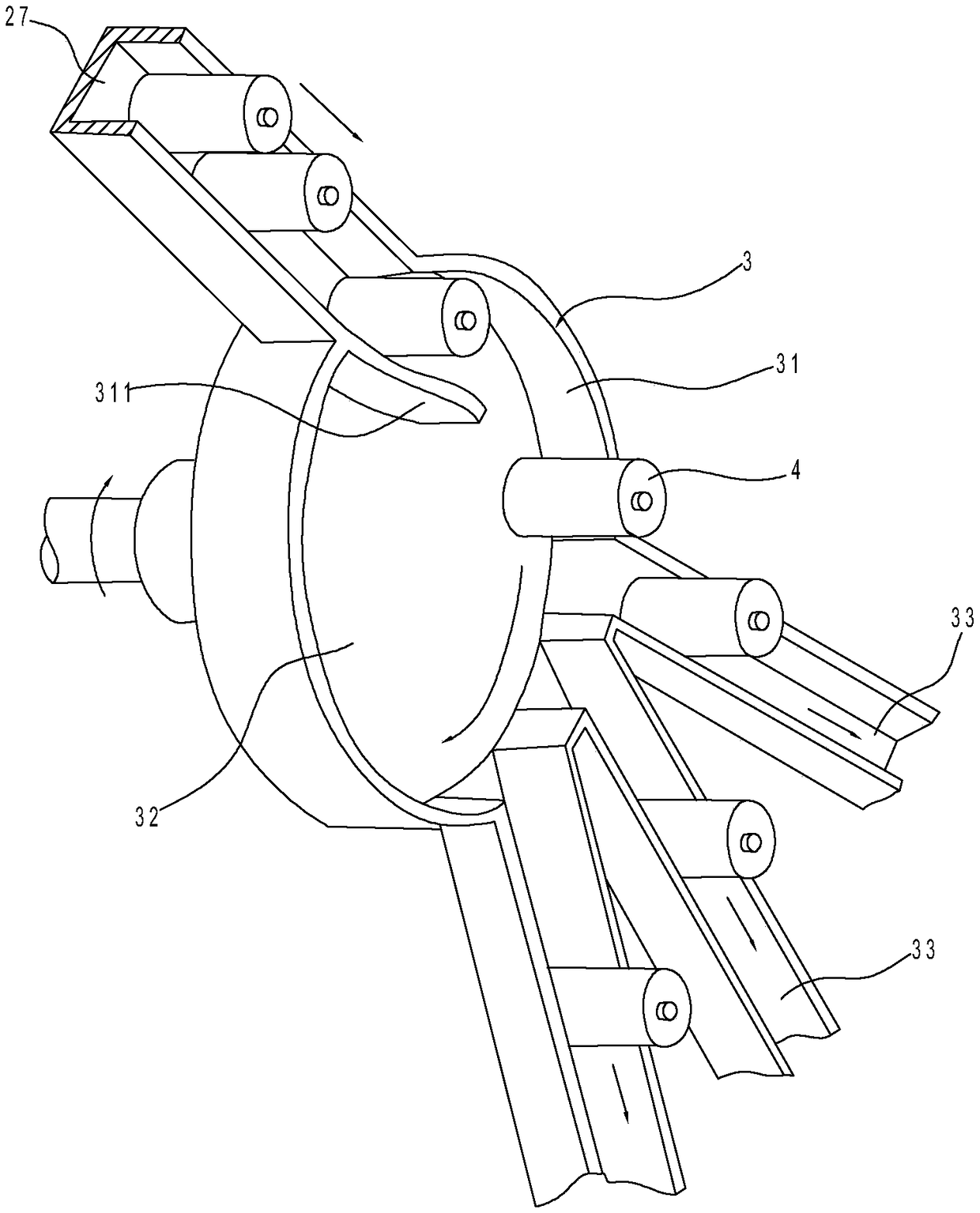

[0022] First, a brief description of the power cell testing and sorting device involved in the present invention is given. like Figures 1 to 3 As shown, the testing and sorting method for power cells in this embodiment includes a testing mechanism 1 , a sorting mechanism 3 and a conversion mechanism 2 , and the conversion mechanism 2 is arranged between the testing mechanism 1 and the sorting mechanism 3 .

[0023] The test mechanism 1 includes a test disk 12 arranged vertically. A plurality of cell slots 121 for horizontally accommodating the power cells 4 are evenly distributed on the outer peripheral wall of the test disk 12. The test disk 12 is controlled to rotate by a sorting motor. , a blanking channel 11 is vertically arranged on the upper part of the test disk 12, the blanking channel 11 can only allow a single lateral passage of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com