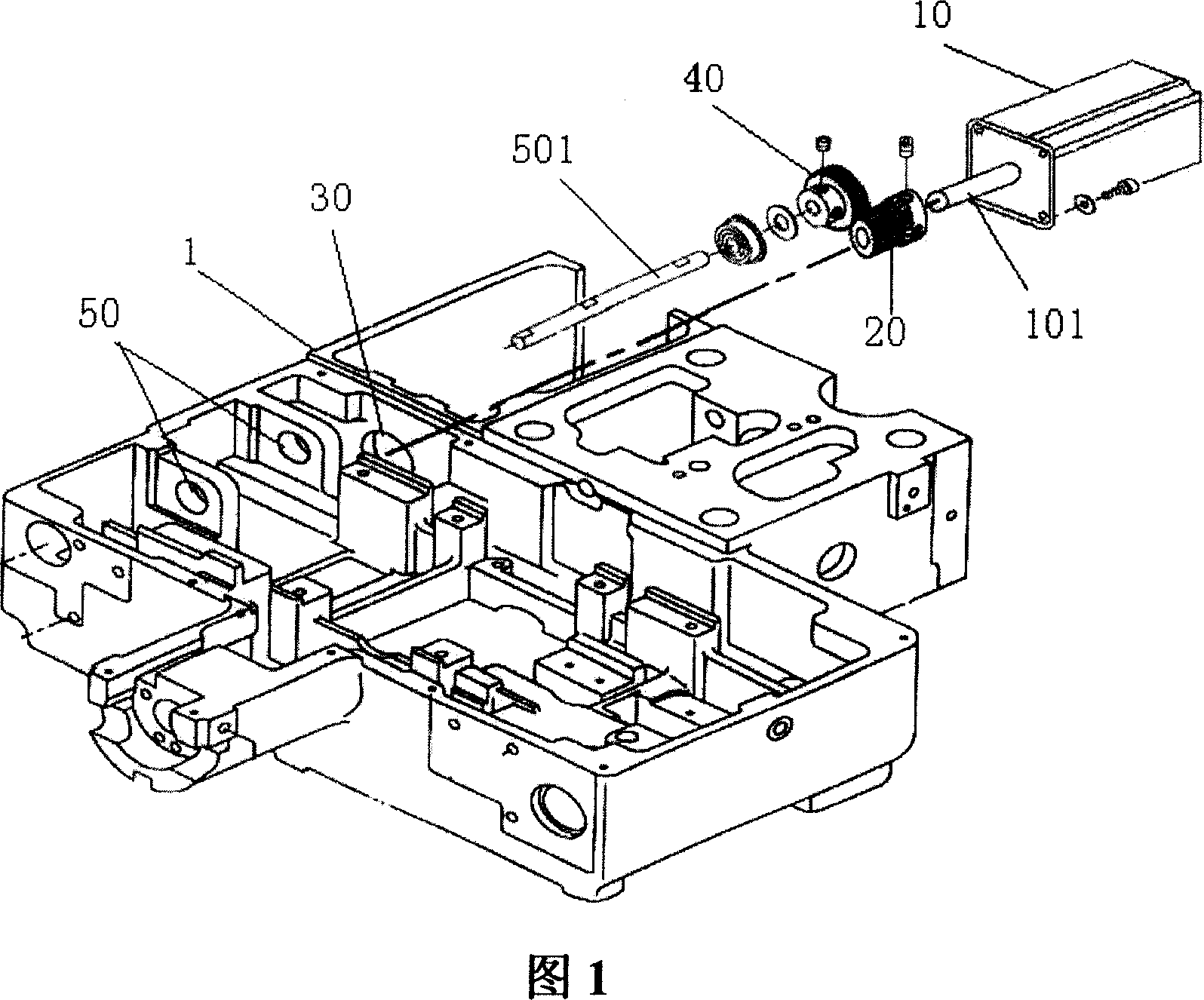

Mechanism for regulating drive at X-direction and inter space of driven gear in electro-pattern-sewing machine

A technology of driven gear and driving gear, applied in the direction of belt/chain/gear, mechanical equipment, sewing machine components, etc., can solve the problems of affecting gear meshing clearance, affecting machine performance, etc., to reduce machining accuracy, prolong service life, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

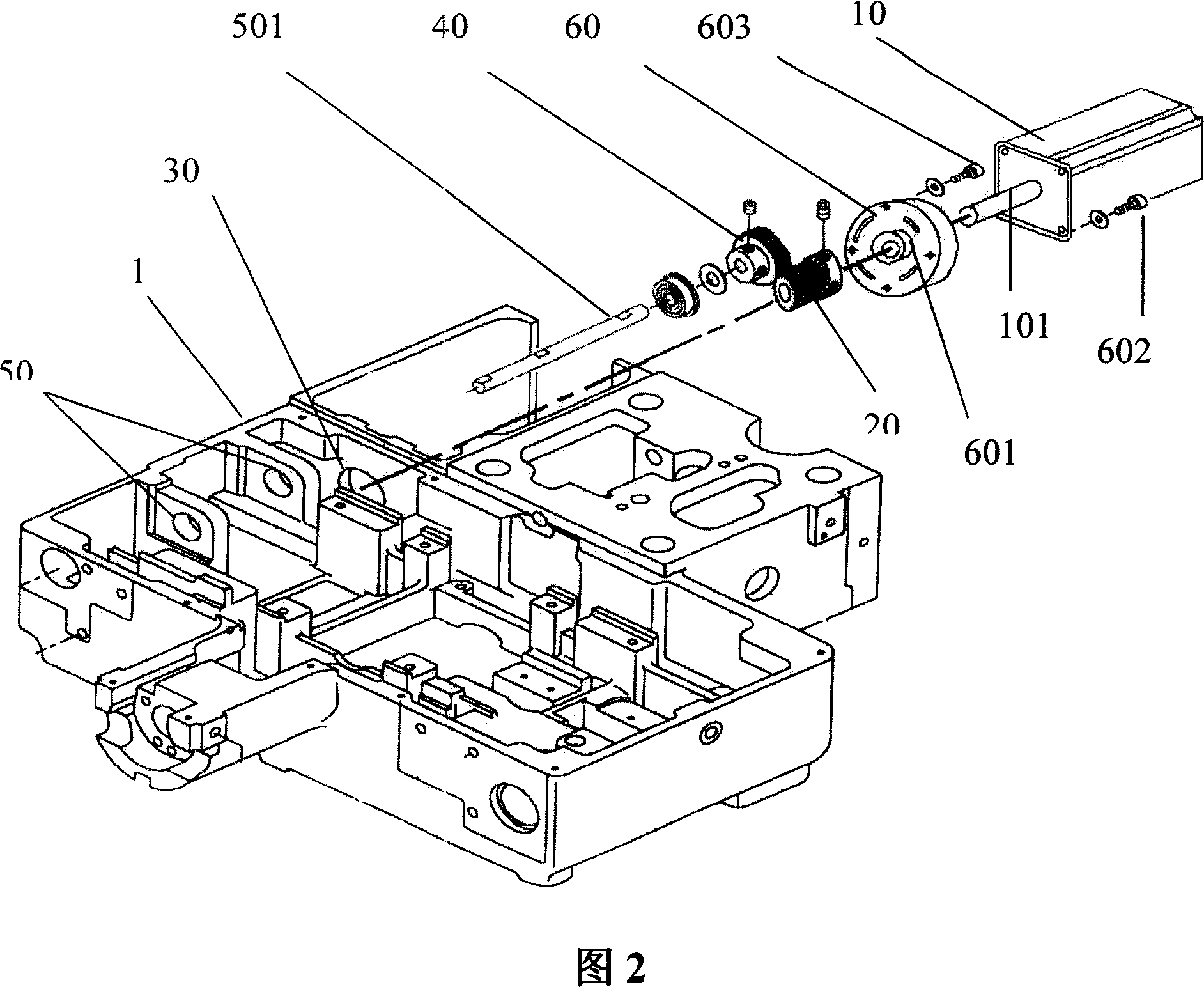

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0012] It can be seen from Fig. 2 that the present invention includes: casing 1, X-direction stepping motor 10, shaft 101 of X-direction stepping motor 10, X-direction driving gear 20, first hole 30, second hole 50, driven gear Installation shaft 501, X-direction driven gear 40; also includes an eccentric adjustment plate 60; described eccentric adjustment plate 60 is on the shaft 101 of the X-direction stepper motor 10, and in the X-direction drive gear 20 and the X-direction step Between the motors 10; one side of the eccentric adjustment plate 60 is fixed to the X-direction stepping motor 10, and the other side is fixed to the plate on which the first hole 30 is placed;

[0013] The outer circle 601 of the boss of the eccentric adjustment plate 60 corresponds to the first hole 30;

[0014] One side of the eccentric adjustment plate 60 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com