Accurate gripping tongs for the machine tool

A flat-nose pliers, precision technology, applied in the field of precision flat-nose pliers, can solve the problems of shortened service life of flat-nose pliers, easy to be too fast or excessive wear, low work efficiency, etc., to achieve clamping accuracy and service life, and not to be too fast Or excessive wear, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

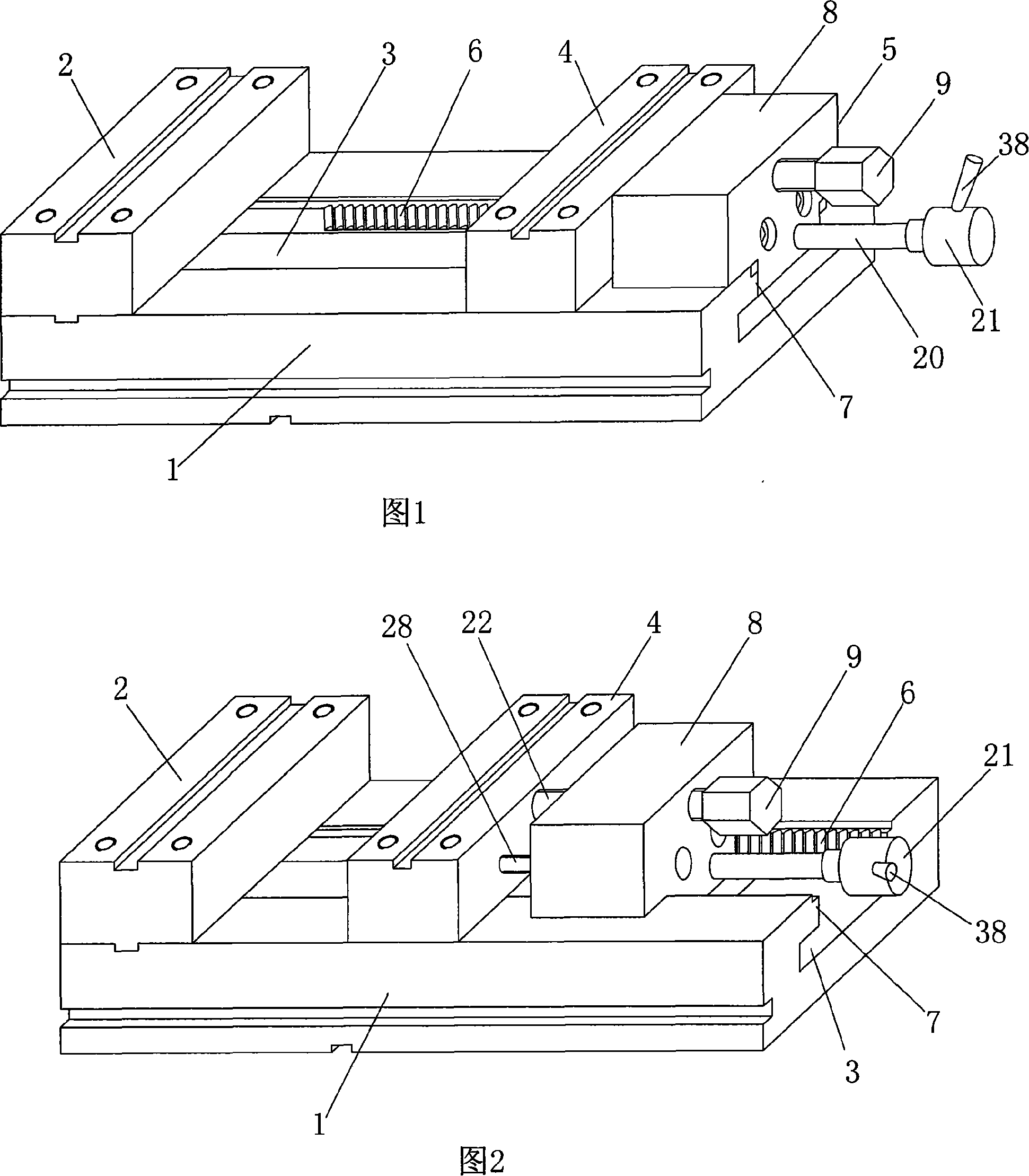

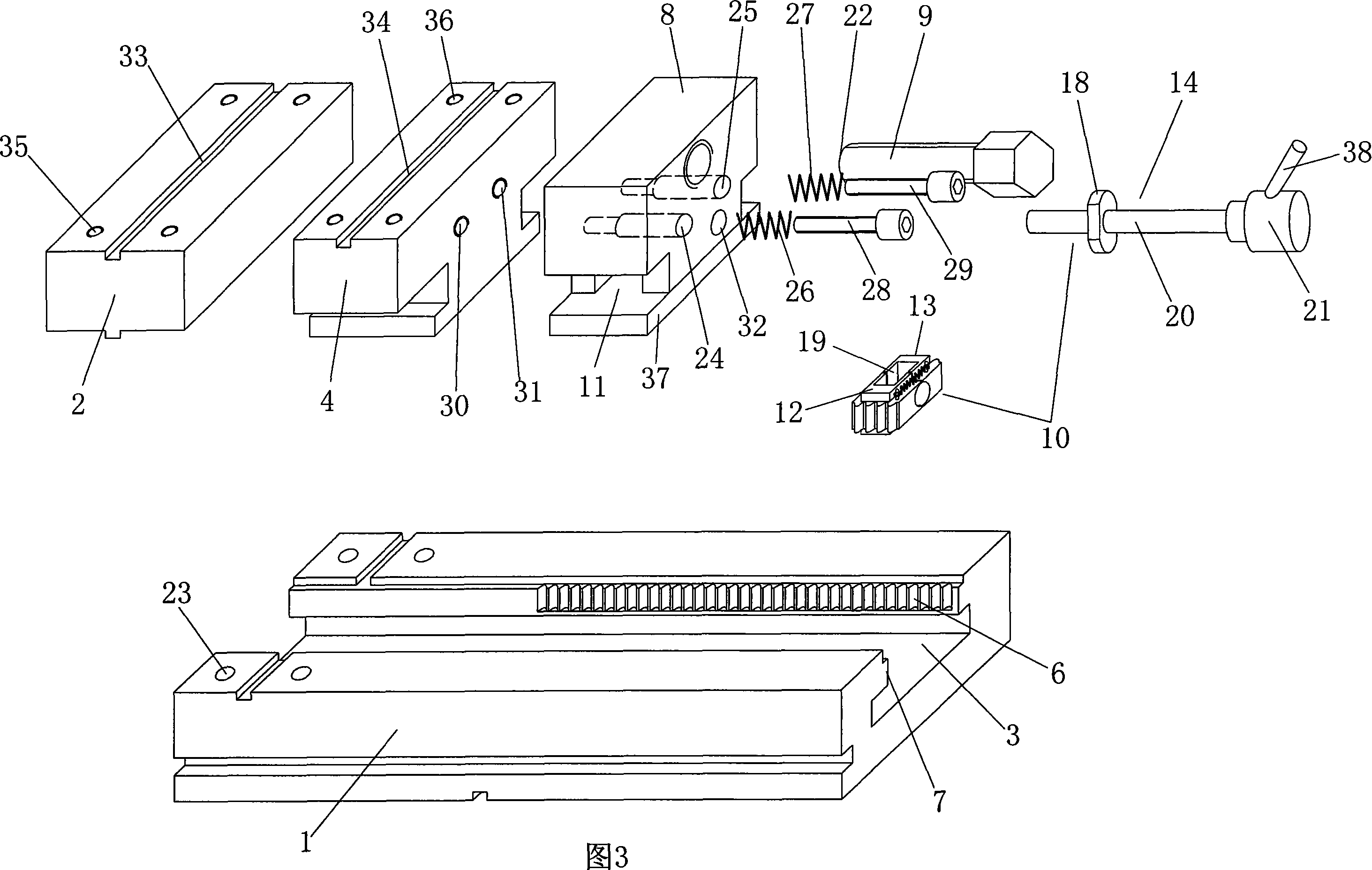

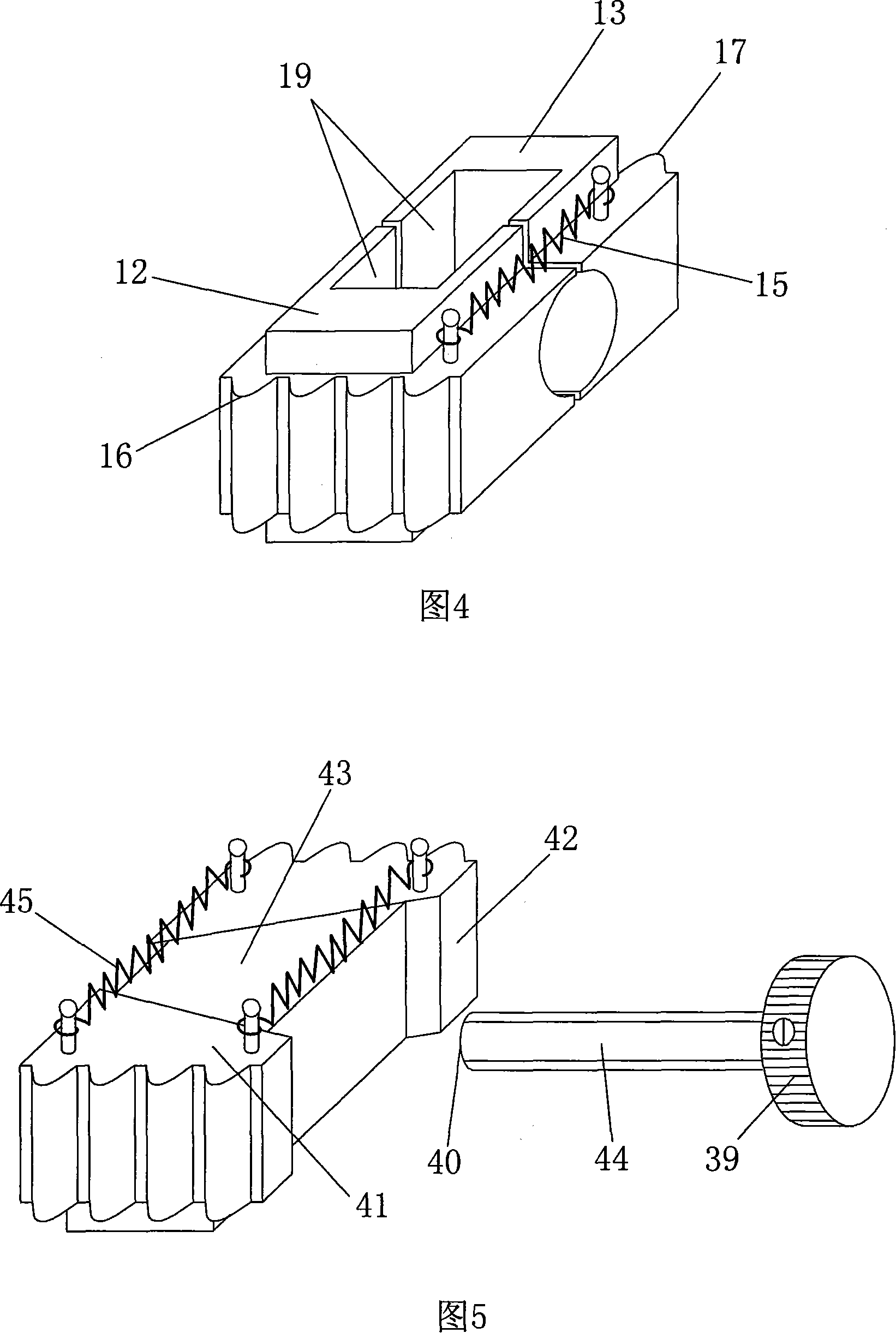

[0016] Referring to Figures 1 to 4, the precision flat-nose pliers used on this machine tool consists of a clamp base 1, a fixed jaw 2 fixed on the clamp base 1, a movable jaw 4 slidingly fitted on the guide rail 3 of the clamp base, and a clamp mounted on the clamp base. The fast moving mechanism 5 matched with the movable jaw 4 on the base 1 is formed, and its characteristic is that racks 6 and 7 are provided on both sides of the guide rail 3 of the clamp base, and the fast moving mechanism 5 is fitted on the guide rail 3 of the clamp base by sliding. The nut seat 8 on the top, the thrust screw 9 threaded on the nut seat 8, and the tensioner 10 arranged on the nut seat 8 are composed of a pair of movable tooth blocks that slide and fit on the inner groove 11 of the nut seat. 12 and 13, expansion and contraction control rod 14, return spring 15, etc., the outer sides of the movable tooth blocks 12 and 13 respectively have tooth rows 16 and 17 engaged with the racks 6 and 7 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com