Washing water tank and hygienic washing device

A technology for hygienic washing and washing water, applied in water supply devices, sanitary equipment for toilets, buildings, etc., can solve the problems of difficult to form complex shapes, heavy water tank weight, deterioration of formability, etc., to achieve extended service life, The effect of small size, compressive strength and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

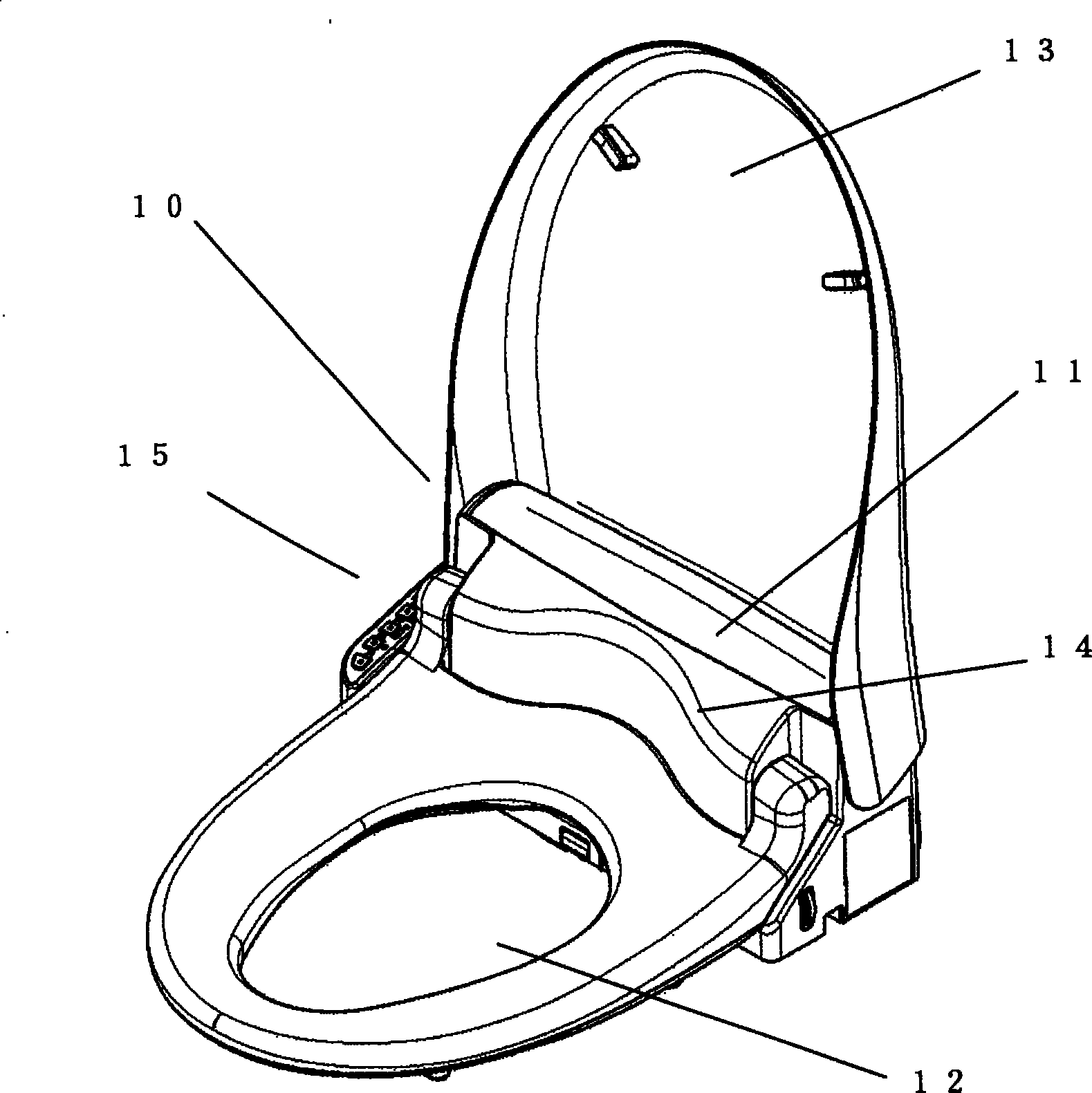

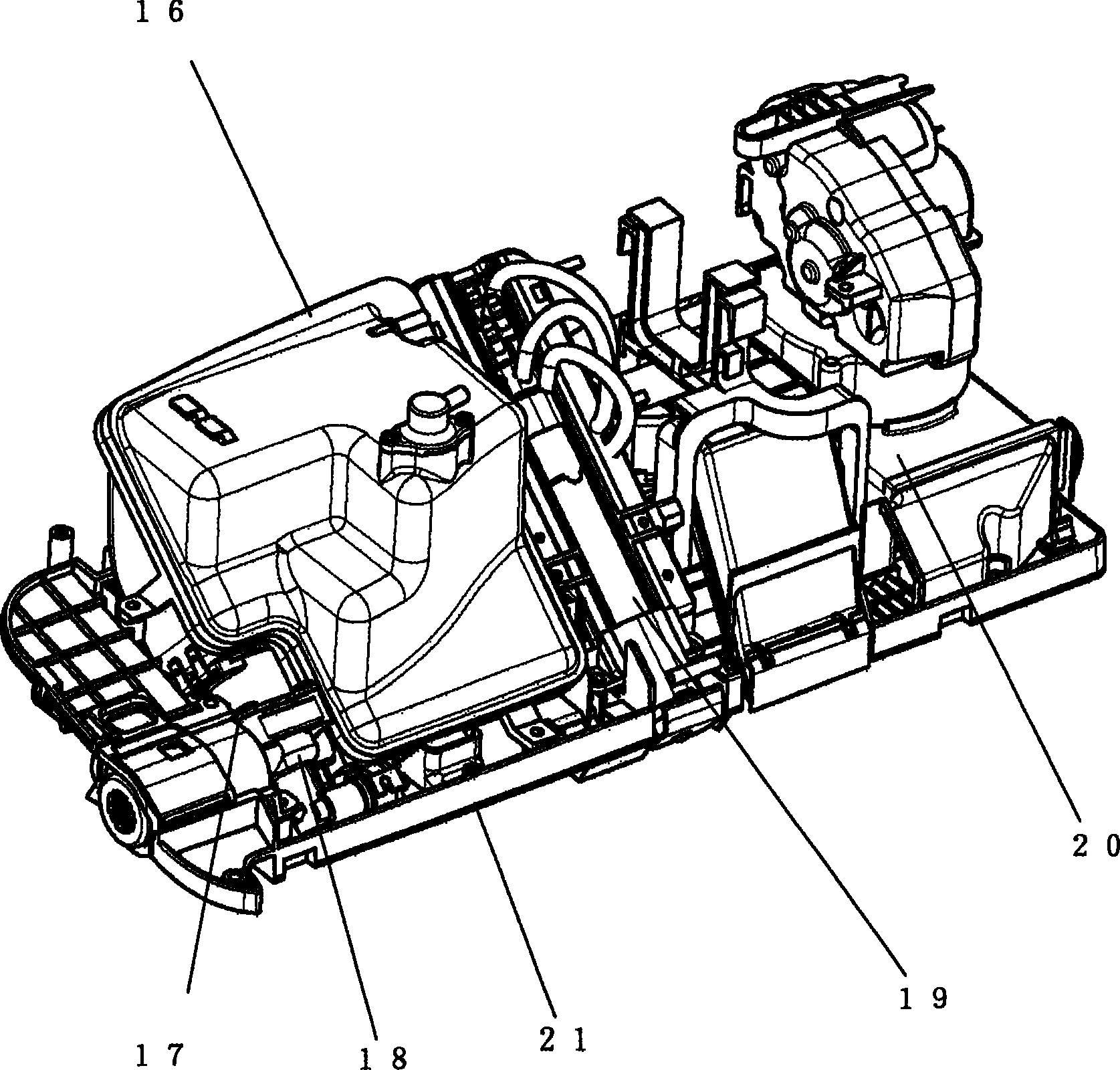

[0047] figure 1 It is a perspective view of the sanitary washing device according to the first embodiment of the present invention, figure 2 It is a perspective view of the state after removing the upper cover of the main body of the sanitary washing device.

[0048] The sanitary washing device 10 of the present embodiment is used by fixing its body 11 on the toilet (not shown), as figure 1 As shown, on the body 11 disposed at the rear of the sanitary washing device 10, the rotating shaft is connected with a toilet seat 12 and a toilet cover 13, and can rotate freely, and the upper cover 14 covers the functional components arranged in the body 11 from above. In addition, an operation unit 15 is integrally provided on the side of the main body 11 .

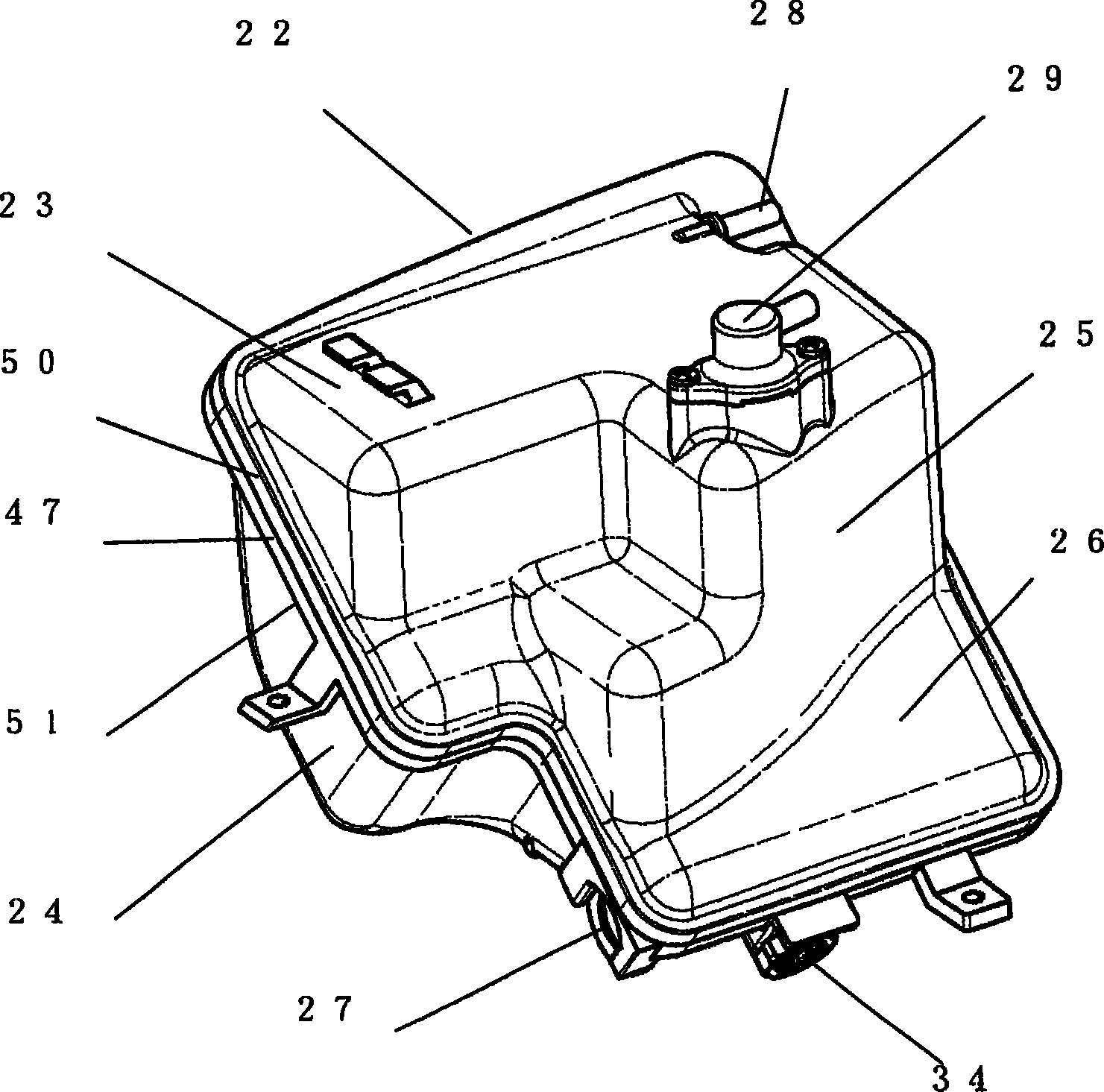

[0049] like figure 2 As shown, inside the main body 11, there are: a washing water tank 16 for storing washing water, a water supply connection part 17 for supplying washing water to the washing water tank 16, and an on-off ...

Embodiment approach 2

[0080] Figure 10 It is a perspective view of the state in which the inside of the main body of the sanitary washing device according to the second embodiment of the present invention is being assembled. Figure 11 It is a perspective view of the state where the flush water tank and related parts are unitized.

[0081] This embodiment differs from the first embodiment in that, as Figure 11 As shown, a part of the reinforcement edge 55 of the water tank body 54 is protruded to form a mounting piece 56 , and the nozzle device 58 is arranged on the water tank body 54 by bolts 57 . In addition, the joint surface 59 of the water tank body 54 is in the same direction as the advancing and retreating direction of the nozzle of the nozzle device 58 . In addition, the on-off valve 18 and the water supply connection part 17 are mounted on the water tank body 54 to constitute the water tank unit 60, such as Figure 10 As shown, on the lower cover 61 of the main body, the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com