Method for controlling air humidity of humiture test box and structure thereof

A humidity control, temperature and humidity technology, applied in the direction of humidity control, temperature control, non-electric variable control, etc., can solve the problem that the humidity verification box cannot meet the requirements of new regulations, it is difficult to meet the requirements of high temperature and high humidity, and the stability and uniformity are inconsistent. Advanced problems, to achieve the effect of ensuring stability and uniformity, high accuracy, and temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

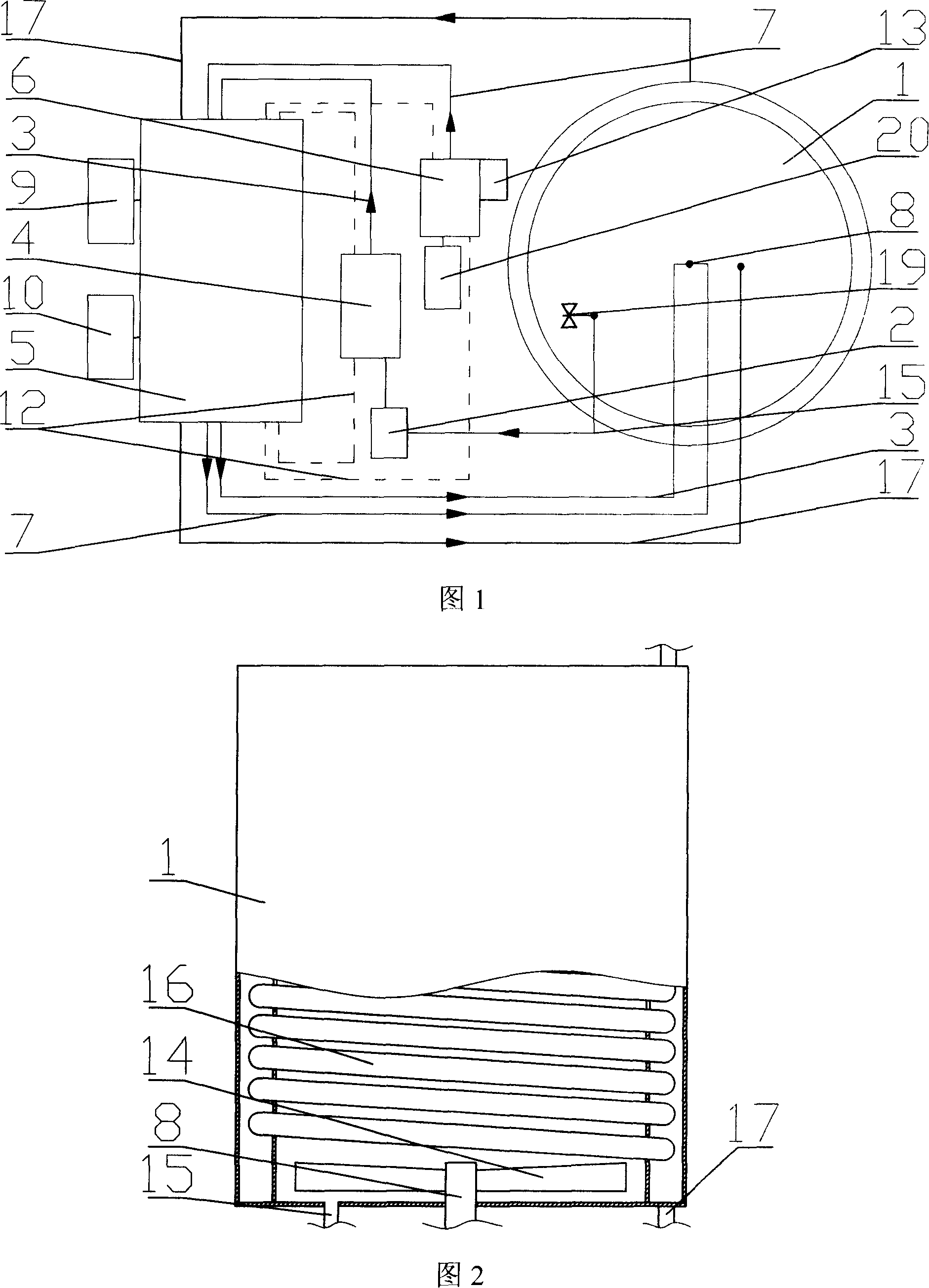

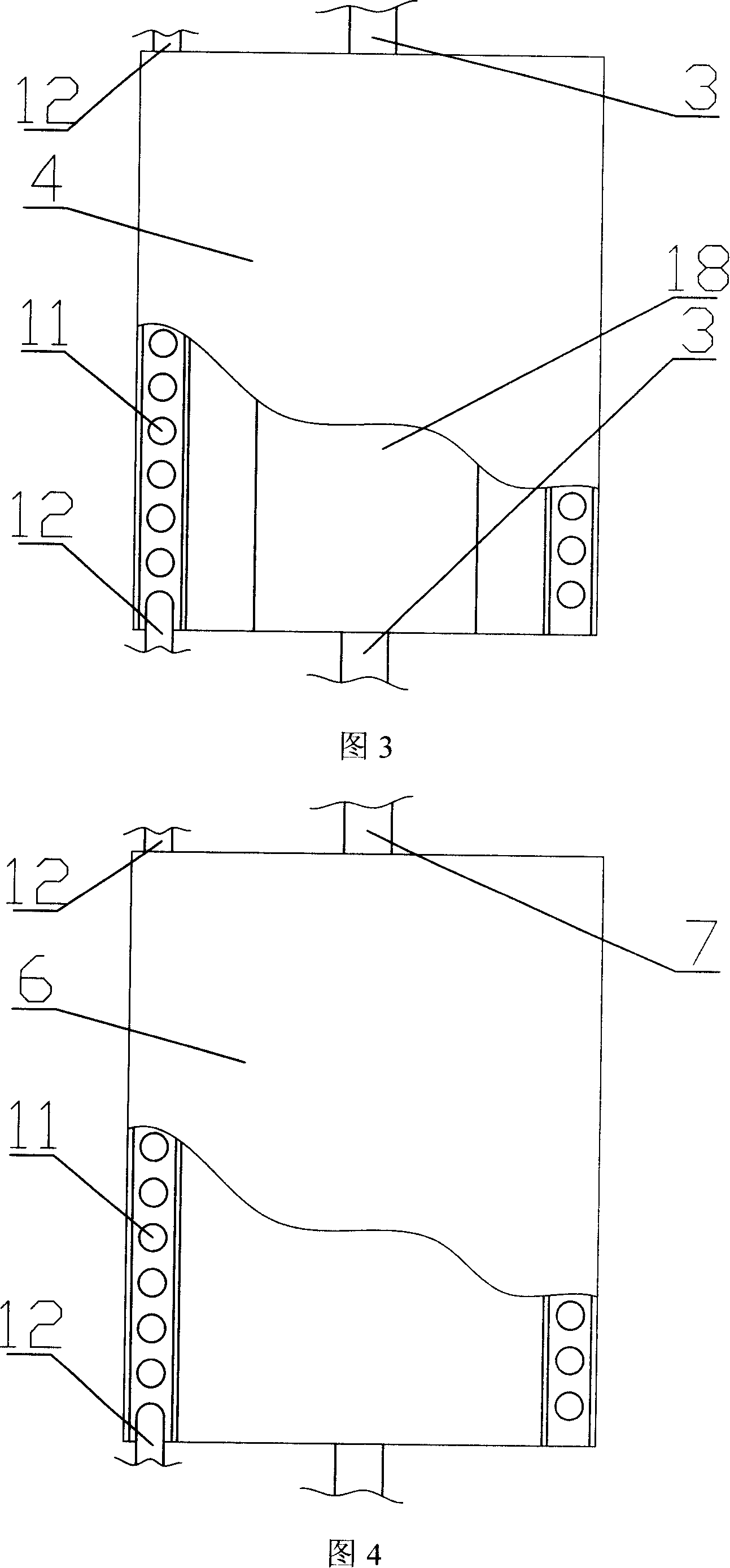

[0015] Embodiment 1 of the present invention: the humidity control structure of temperature and humidity test box, it comprises the work area (1) of test box, and work area (1) is a sealed cylindrical structure, is provided with in front of work area (1) The interface (8) for conveying dry gas and wet gas is equipped with a fan (14) inside the interface (8), and a circulation pipe (15) is connected to the front of the work area (1), so that the gas in the work area (1) Send into dryer (4) and recycle, also install a vent valve (19) on the circulation pipeline (15), use when adding moisture. Install the fan (2) in the verification box, the outlet of the fan (2) is connected to the pipe (3), and the pipe (3) passes through the constant temperature water tank (5) and is connected to the interface (8) of the work area (1). The circulating pipe (15) on (1) is connected to the inlet of the fan (2); a fan (20) is also installed in the test box, and the fan (20) is connected to the sa...

Embodiment 2

[0021] Embodiment 2 of the present invention: the making of verification box has working area (1), and working area (1) is a sealed cylindrical structure, is provided with the interface ( 8), install the fan (2) in the test box, the outlet of the fan (2) is connected to the pipe (3), and the pipe (3) passes through the constant temperature water tank (5) and is connected to the interface (8) of the work area (1), A circulation pipe (15) is provided on the work area (1), and the circulation pipe (15) is connected to the inlet of the blower fan (2); the gas in the work area (1) is sent to the dryer (4) for recycling, and the circulation Also install a vent valve (19) on the pipeline (15), use when adding moisture. Install the fan (20) in the test box, the fan (20) is connected to the saturator (6) through the pipeline, the moisture pipeline (7) is connected to the saturator (6), and the moisture pipeline (7) passes through the constant temperature water tank (5) Then connect to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com