Expiratory valve

A technology of exhalation valve and valve core, applied in the field of exhalation valve, can solve the problems of no holding force, high price, slow response speed of air-controlled exhalation valve, etc., and achieve the effect of easy implementation, fast response speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

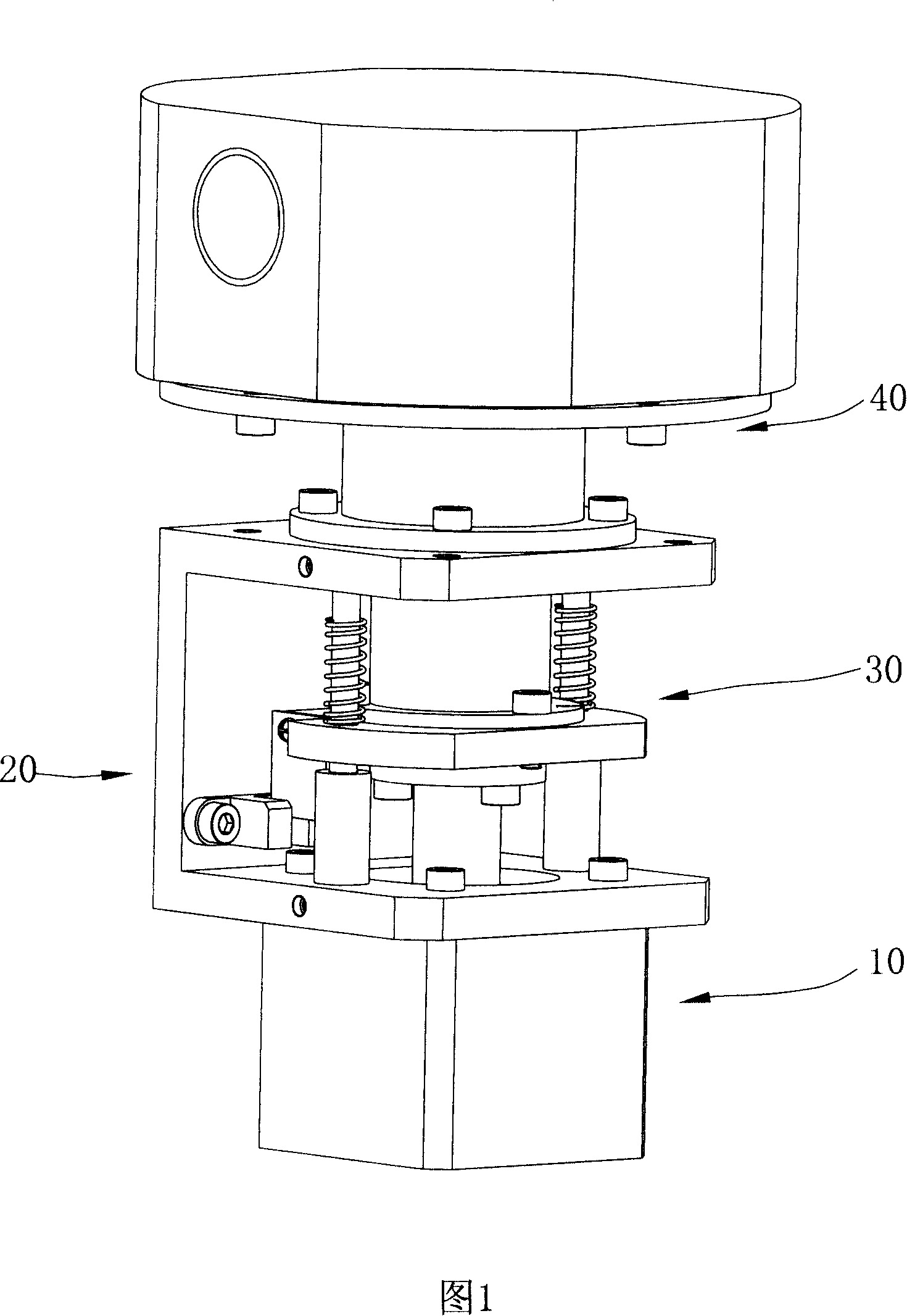

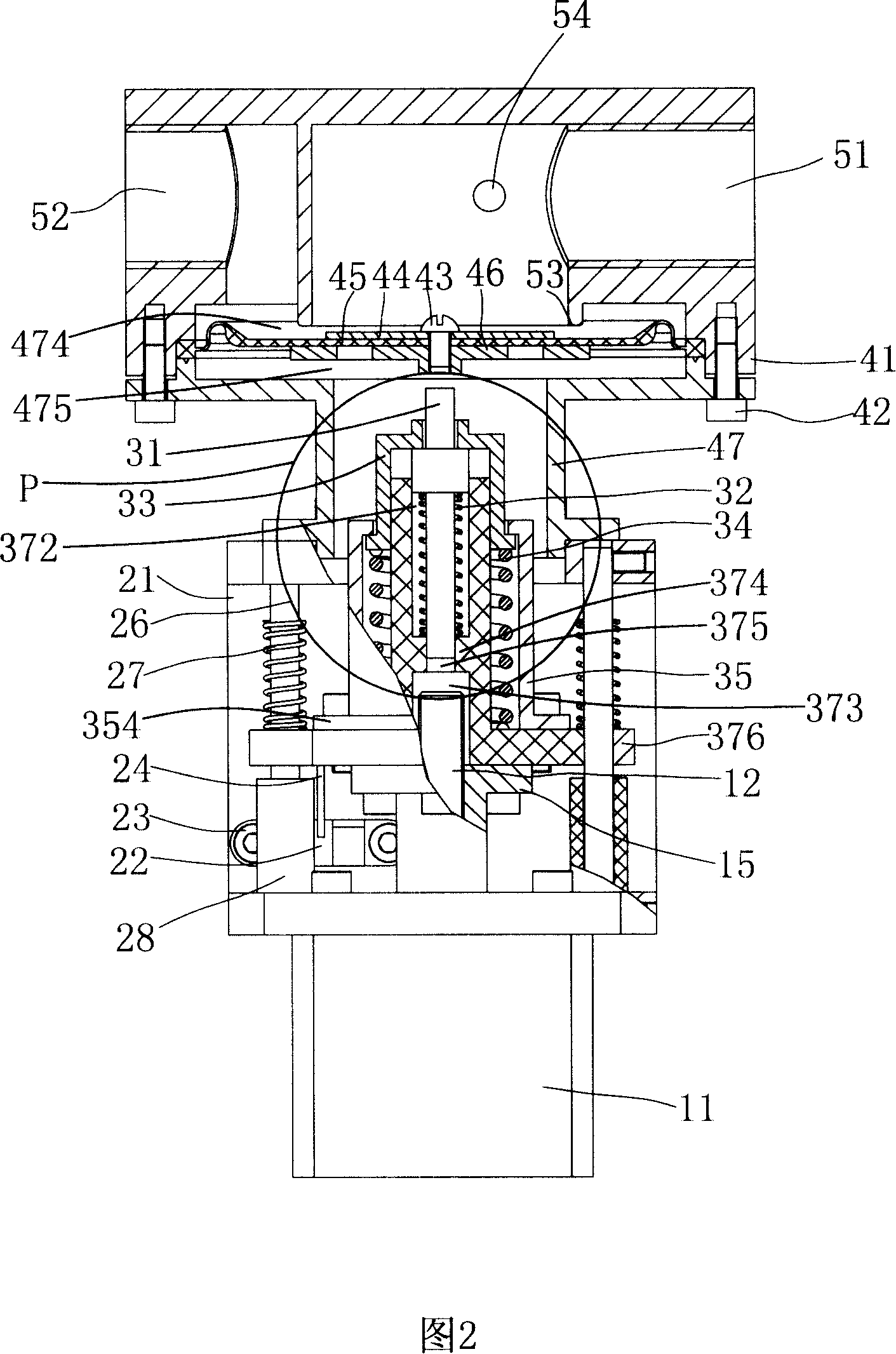

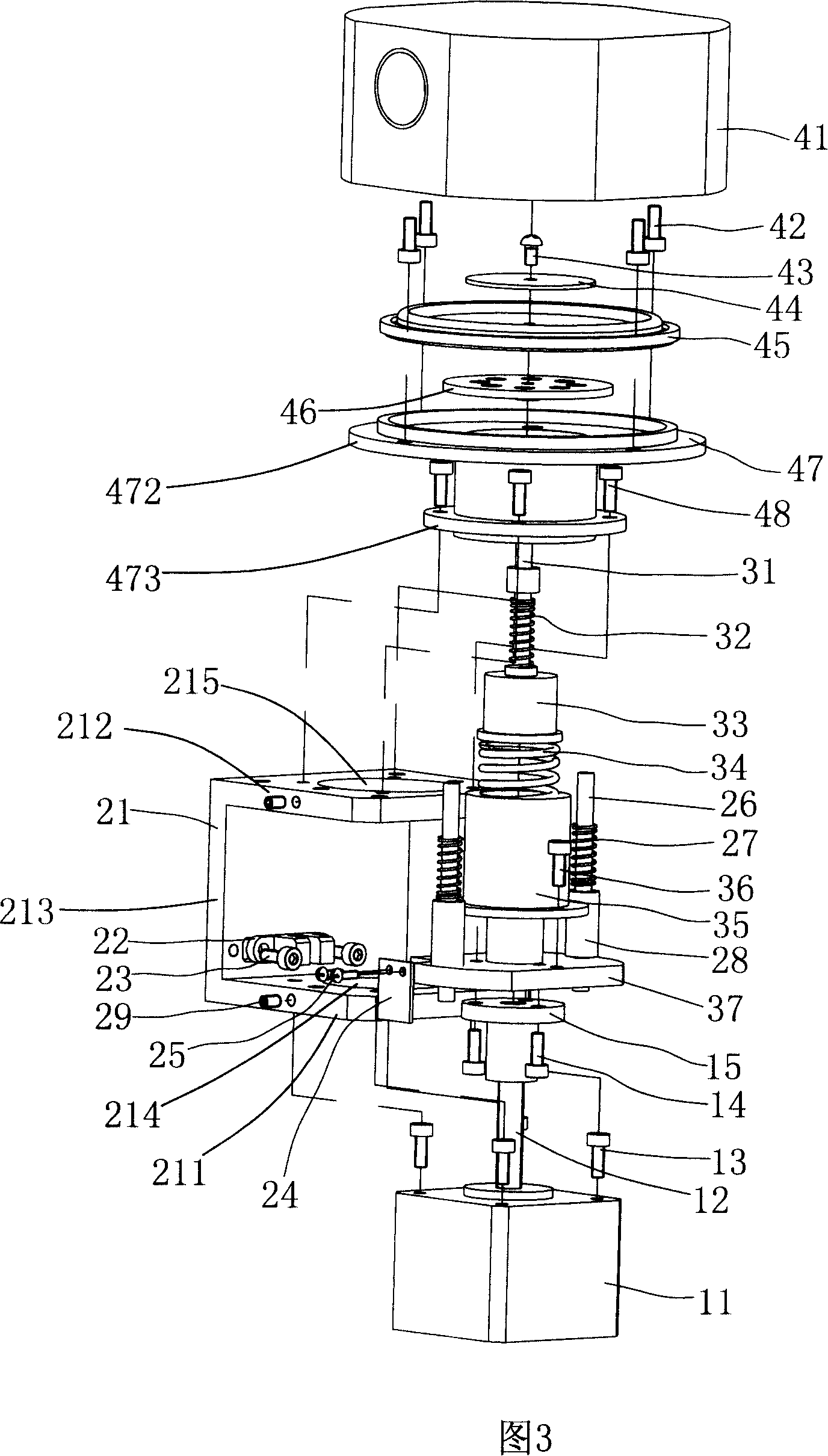

[0024] Please refer to FIG. 1 to FIG. 4 , the exhalation valve of the present invention is placed vertically when in use, and it includes a motor drive unit 10 , a bracket and sensor unit 20 , a double spring ejector unit 30 and an exhalation valve body unit 40 .

[0025] The motor drive unit 10 is used to provide power for the entire exhalation valve, which includes a motor 11 and a transmission mechanism, the motor is used to provide power, and the transmission mechanism is used to convert the rotational motion of the motor into linear motion. In this embodiment , the transmission mechanism is a lead screw nut pair, and the lead screw 12 of the lead screw nut pair is the exposed part of the motor shaft.

[0026] The bracket and the sensor unit 20 are connected with the motor drive unit 10 and the double-spring ejector unit 30, which provide support and linear motion guidance for the entire exhalation valve. The bracket and sensor unit 20 includes a motor bracket 21 , a guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com