High performance kinetic spray nozzle

A technology of power spraying and nozzle, applied in the direction of spraying device, spraying device, liquid spraying device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention includes references to, for example, U.S. Patent Application No. 2005 / 0214474A1, U.S. Patent Nos. 6,139,913 and 6,283,386, and Van Steenkiste et al., published Jan. 10, 1999 in Surface and Coatings Technology, volume III, pp. 62-72. Improvements made to the power spray system and nozzle assembly 20 are primarily described in the document entitled "Power Spray Coating". The disclosures of all of the above documents are hereby incorporated by reference.

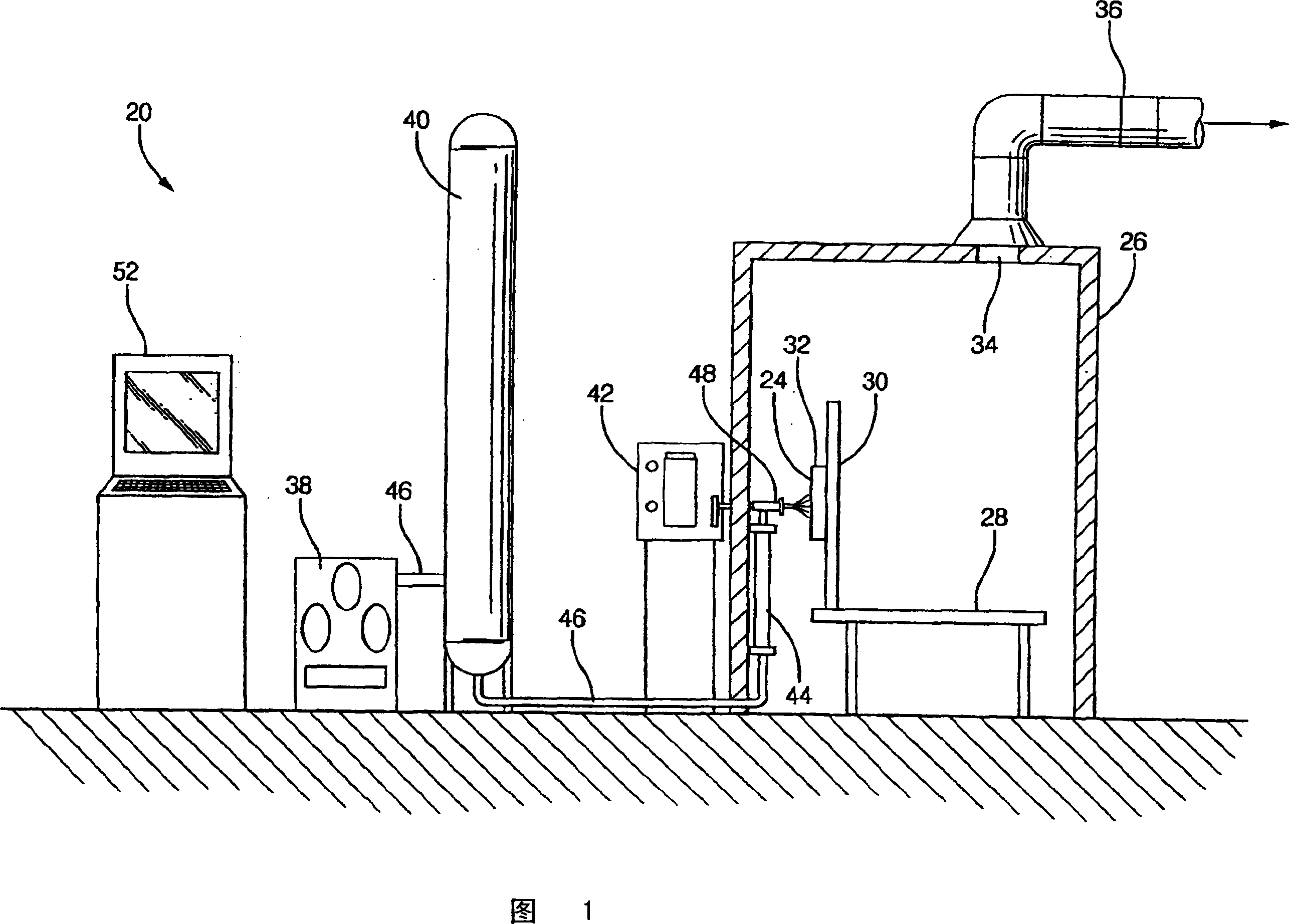

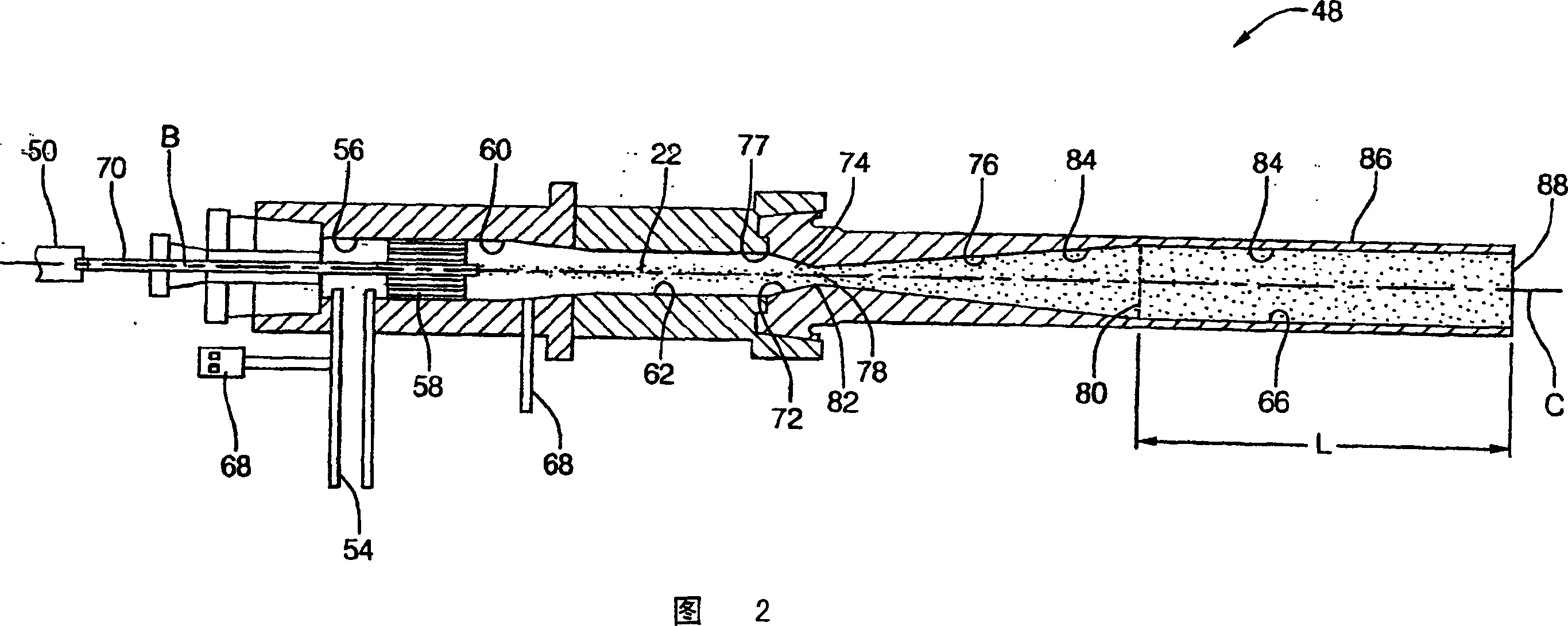

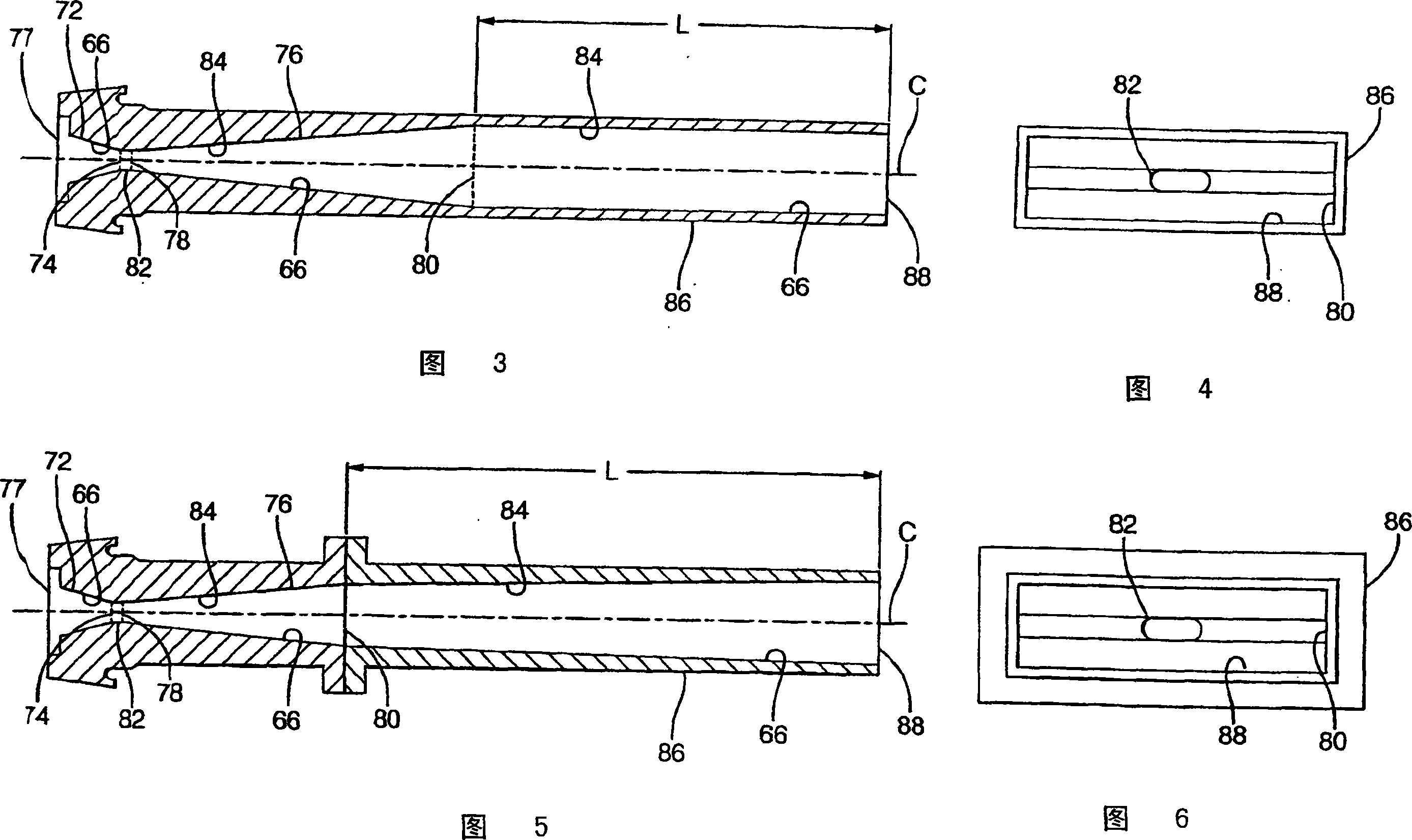

[0020] Referring to the drawings in which like reference numerals are used to indicate corresponding parts, the power spray system is generally indicated by the reference numeral 20 . Referring to FIG. 1 , a powered spray system 20 applies a coating of powder particles 22 to a substrate material 24 . The heated gas stream suspends powder particles 22 which are then sprayed onto substrate material 24 at high velocity. As disclosed in U.S. Patent No. 6,139,913, base material 24 may comprise any of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com