Closing-sunning type solar energy methane tank

A solar energy and biogas digester technology, applied in the field of biogas digesters, can solve the problems of high pressure in fermentation pools, potential safety hazards, poor heat collection effect in digesters, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below in conjunction with embodiment and accompanying drawing.

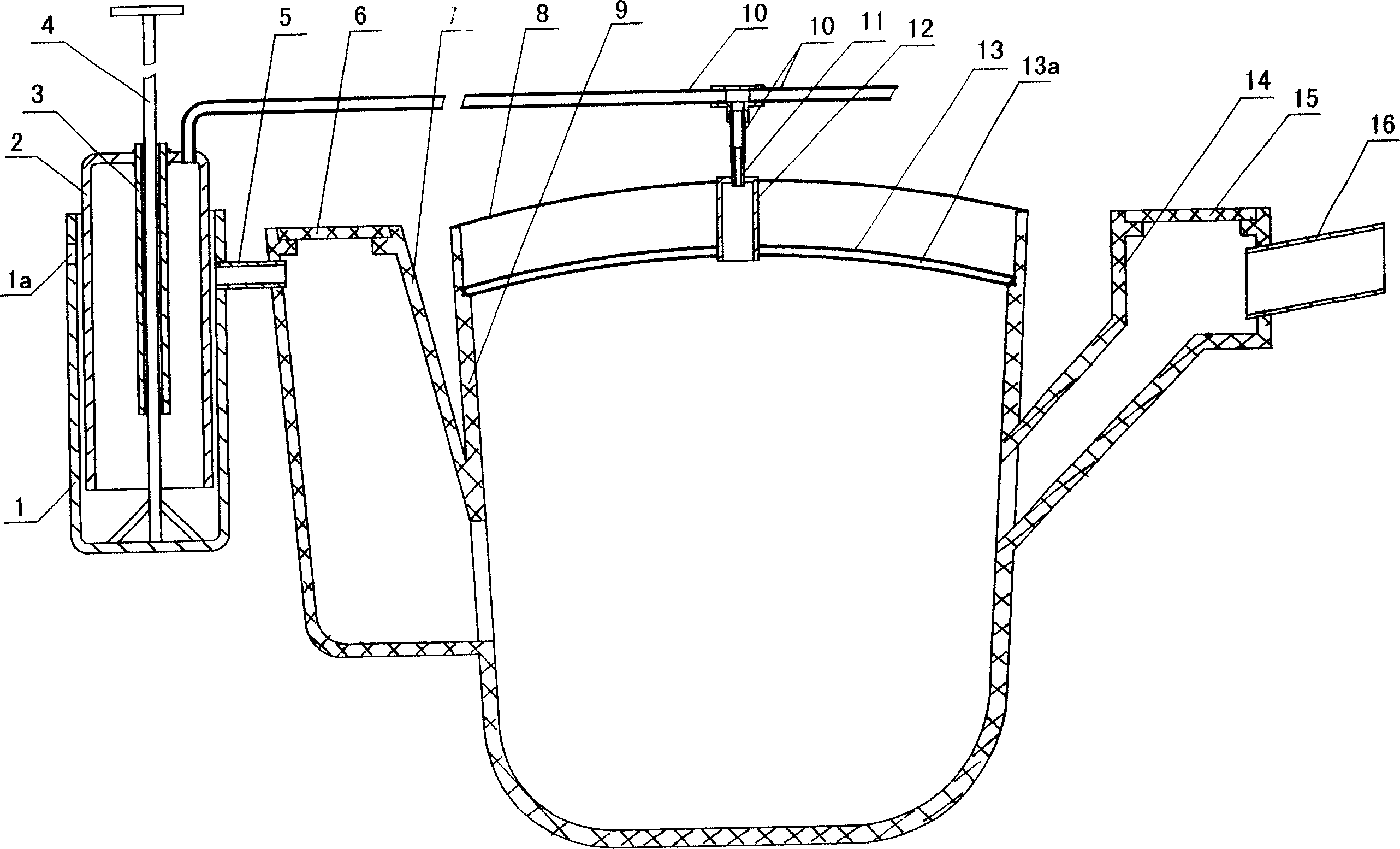

[0010] see attached image

[0011] Both sides of fermentation tank 9 are respectively provided with feed tank 14, discharge tank 7, feed tank 14, discharge tank 7 are connected with fermentation tank 9, and the upper end of fermentation tank 9 is covered with light-transmitting vault 13, arch The material of top 13 can be plexiglass, plastics or glass etc. Vault 13 is arched and has hollow interlayer 13a inside, and this interlayer 13a can also be a vacuum, like this, its thermal insulation performance will be better. The way that the air guide pipe 11 communicates with the inside of the fermentation tank 9 from the middle part of the vault 13 is that a hollow pipe cap 12 is connected at the center of the vault 13, and the inner cavity of the pipe cap 12 communicates with the fermentation tank 9 inside, and the guide The trachea 11 is connected to the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com