Spring magnetic control superposed type fuel gas motor relief valve

A motor safety and magnetic control technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of poor airtightness, easy combustion, explosion accidents, short valve opening stroke, etc., to ensure safety and reliability The effect of eliminating safety hazards and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

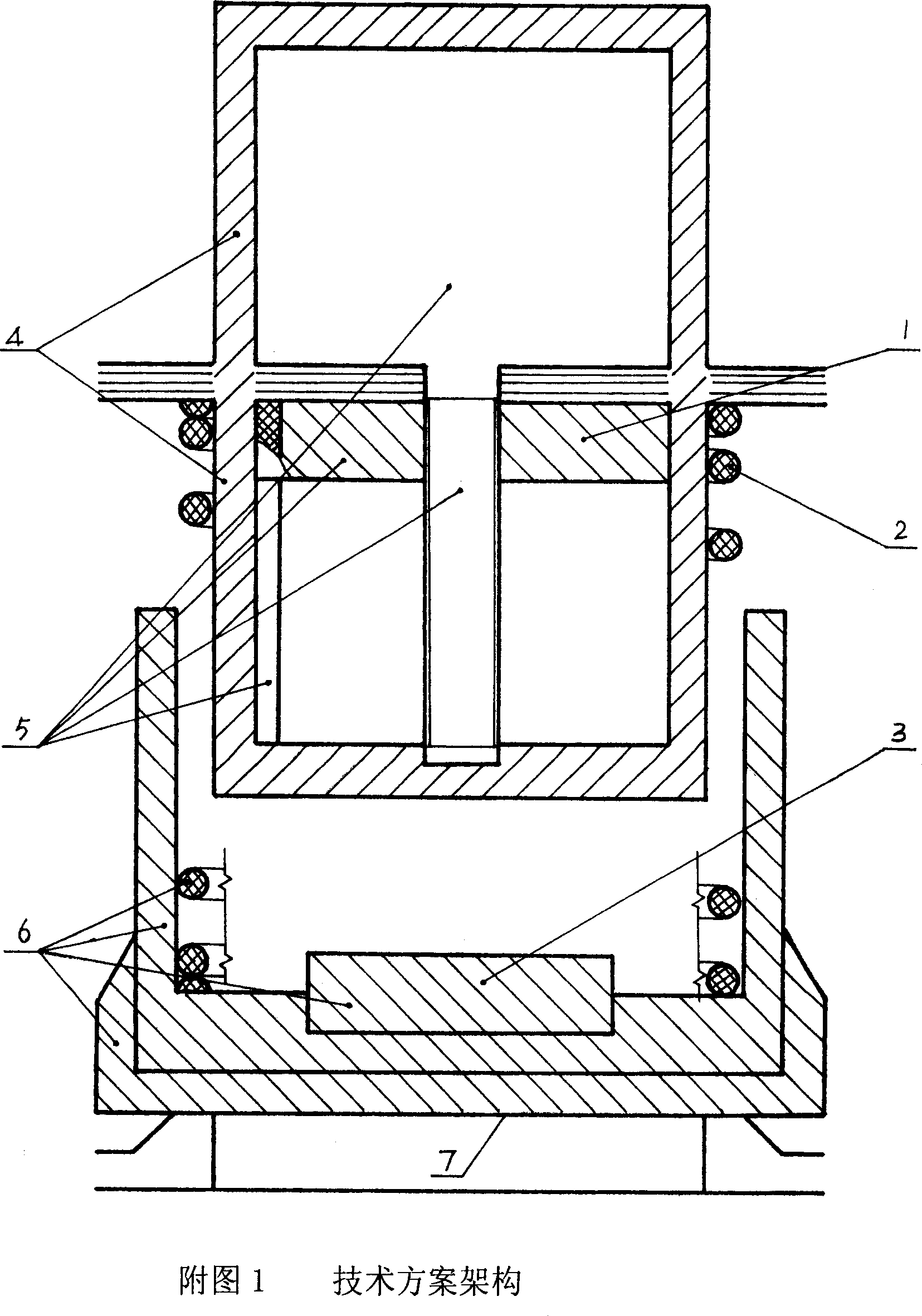

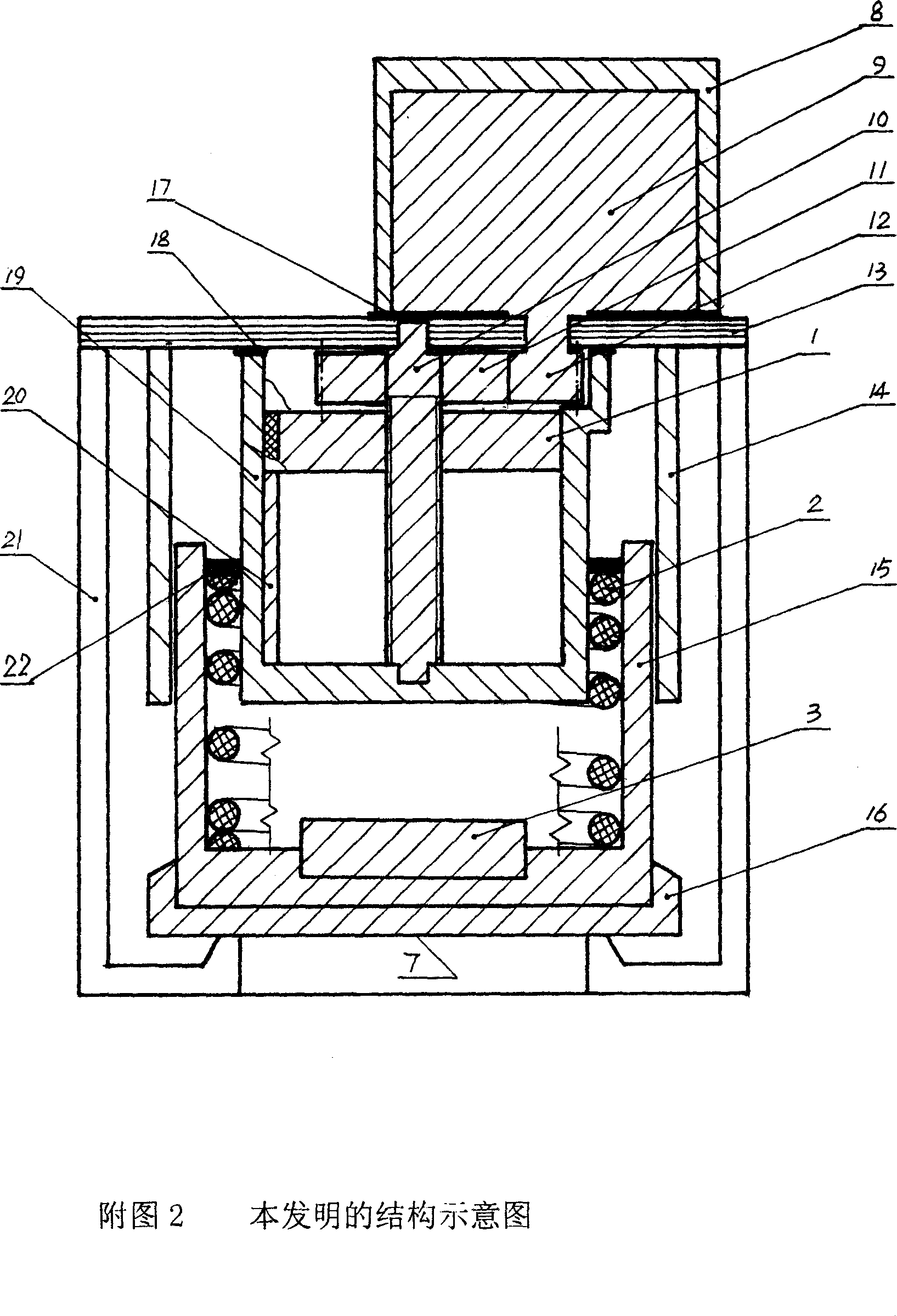

[0010] A spring magnetic control coincidence type gas motor safety valve, the structure of the valve core is mainly composed of a group of magnets with opposite sexes and a spring, a fully enclosed motor box, a motor screw transmission mechanism, a U-shaped valve cover mechanism, and a valve body Its characteristics are: a. Provide a main magnet and auxiliary magnet with opposite sexes and a spring structure as the power source for opening and closing the valve; b. Provide a complete structure of the motor box and the main magnet displacement box structure Closed motor box; c. Provide a motor screw transmission mechanism that drives the displacement of the main magnetic steel, sealed in the inner cavity of the fully enclosed motor box; d. Provide a spring, integrated with the valve cover and auxiliary magnetic steel to form a U with synchronous movement as a whole e. The U-shaped valve cover mechanism provided can coincide with the main magnetic steel displacement box during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com