Embedded type weighing system based on intelligent fuzzy control

A fuzzy control and weighing system technology, which is applied in the field of weighing systems in the batching and conveying process, can solve the problems of low accuracy, inability to adapt to the comprehensive batching and conveying system, and low stability, so as to improve the accuracy of calculation , Fault finding is convenient and fast, and the effect of the accuracy of calculation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

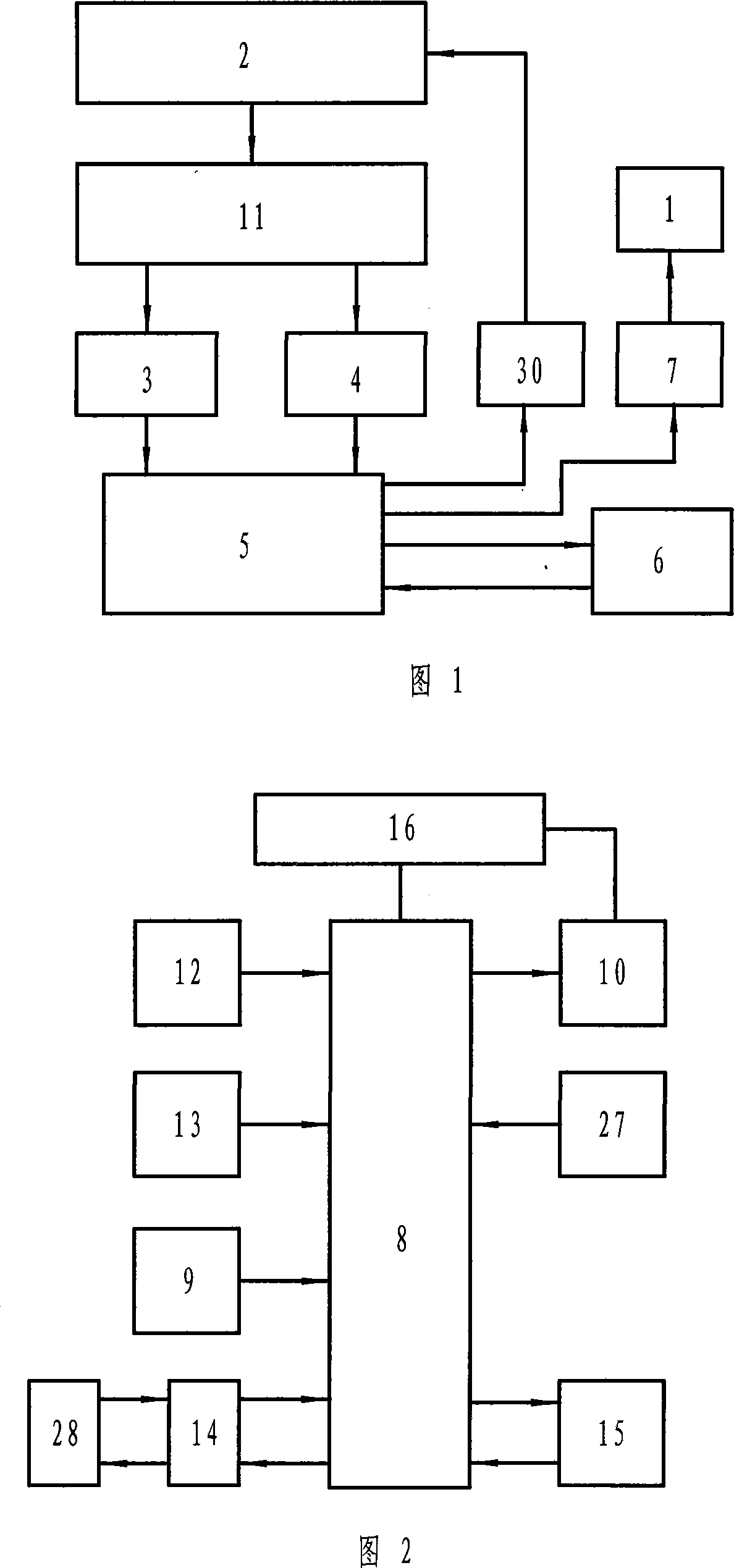

[0029] Fig. 1 is the structural representation of the embedded weighing system based on intelligent fuzzy control of the present invention, and the embedded weighing system based on intelligent fuzzy control shown in the figure mainly includes: feeder 1, main conveyor 2, weight sensor 3. Speed sensor 4, weighing display controller 5, host computer 6, frequency converter 7, batching belt scale 11 and programmable controller 30, its structure is: weighing display controller 5 is respectively connected to weight sensor 3, The speed sensor 4, the upper computer 6, the frequency converter 7 are connected to the programmable controller 30, the weight sensor 3 and the speed sensor 4 are respectively connected to the batching belt scale 11 through wires, and the batching belt scale 11 is connected to the main conveyor 2 through wires. Conveyor 2 is also connected with programmable controller 30 by wire, and feeder 1 is connected with frequency converter 7 by wire; Its data transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com