Rotary ultrasonic motor and its implementation method

An ultrasonic motor and rotary technology, applied in the field of electric motors, can solve the problems of low driving force, high cost, and increased cost, and achieve high torque, self-locking force when power is off, large driving force, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

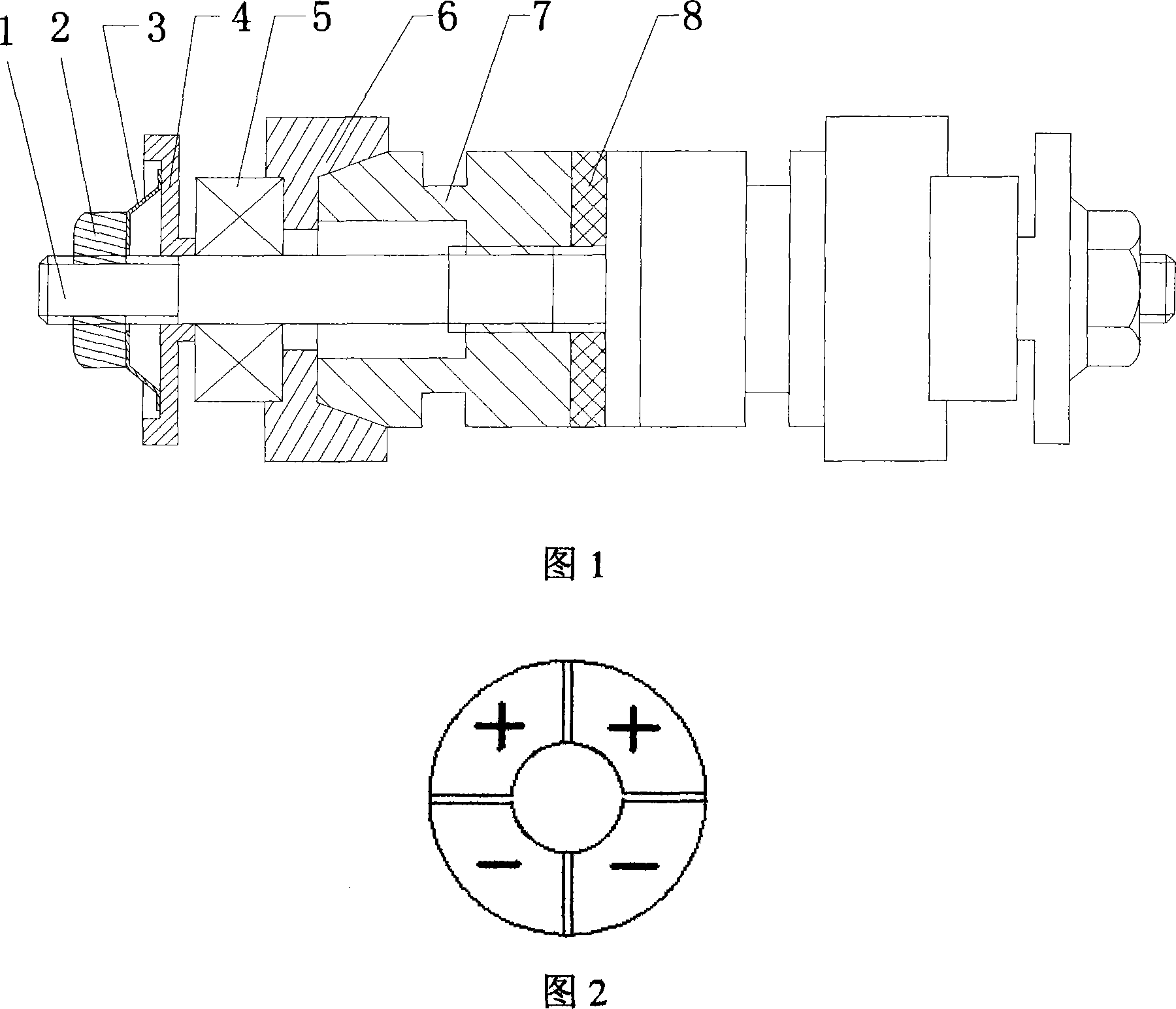

[0018] As shown in Figure 1, a double-rotor rotary ultrasonic motor is symmetrically arranged on the screw 1 with a set nut 2, a disc spring 3, a tray 4, a bearing 5, a rotor 6, a stator 7, and a piezoelectric ceramic sheet 8 , the piezoelectric ceramic sheet 8 is fixed in the middle of the screw rod 1 by threads, the stator 7 is fixed on the screw rod 1 by threads, the end of the stator 7 adjacent to the rotor 6 is a conical surface, and the end adjacent to the rotor 6 and the stator 7 is a conical surface. The inner conical face of the face mate. The bearing 5 is adjacent to the rotor 6 , the disc spring 3 presses the bearing 5 through the tray 4 to press the conical surface, and the set nut 2 adjusts the preload of the disc spring 3 . The screw 1, the set nut 2, the disc spring 3, the tray 4 and the bearing 5 constitute the preload applying system of the motor, and the preload applied to the rotor 6 is adjusted by adjusting the deformation of the disc spring 3 at both ends....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com