Propellant burning gas mole number test method and its device

A technology of combustion gas and test method, applied in the direction of volume measurement instrument/method, measurement device, liquid/fluid solid measurement, etc., to achieve the effect of broadening the scope of application and avoiding process errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

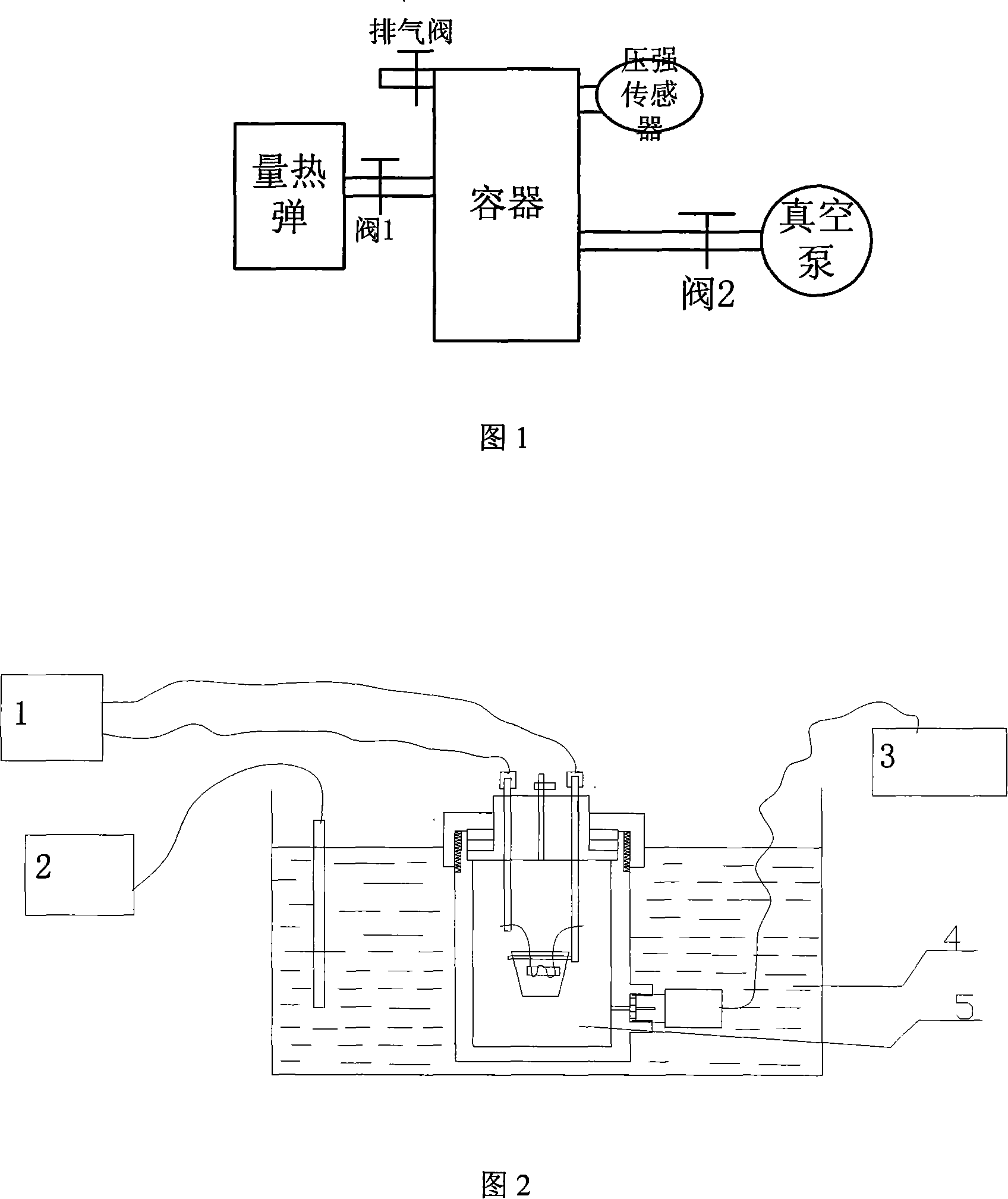

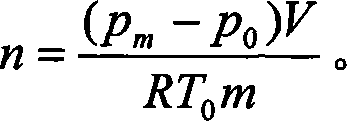

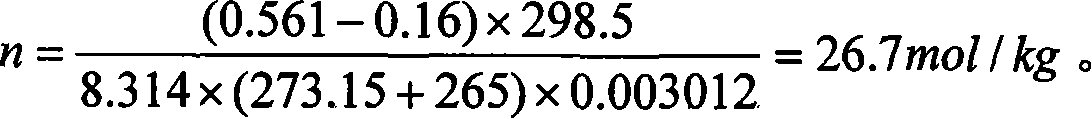

[0016] Device embodiment: with reference to Fig. 1, main body device of the present invention is calorimetric bomb, adopts YD-00 type oxygen bomb, is made of stainless steel, and volume is about 250ml ± 10ml~350ml ± 10ml, should be qualified through 30MPa hydrostatic test. A small hole for testing the pressure is opened on the body of the calorimetric bomb, which is connected with the pressure sensor. The pressure sensor adopts a pressure transmitter with a model number of CYH300 and a range of 0 to 5 MPa. Both the calorimetric bomb and the temperature sensor are submerged under the liquid level of the oil bath constant temperature tank, and the ignition device is placed inside the calorimetric bomb. The ignition device adopts 0-20V adjustable regulated power supply; the temperature sensor adopts SWJ-Ic precision digital thermometer with a measuring range of 0-650°C; the oil bath thermostat adopts HH-S digital display constant temperature oil bath, and the medium It is liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com