Magnetostrictive guide wave damage-free detection method

A magnetostrictive, defect-free technology, applied in the direction of material analysis using sonic emission technology, which can solve problems such as difficulty, low detection accuracy, and single-mode guided waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

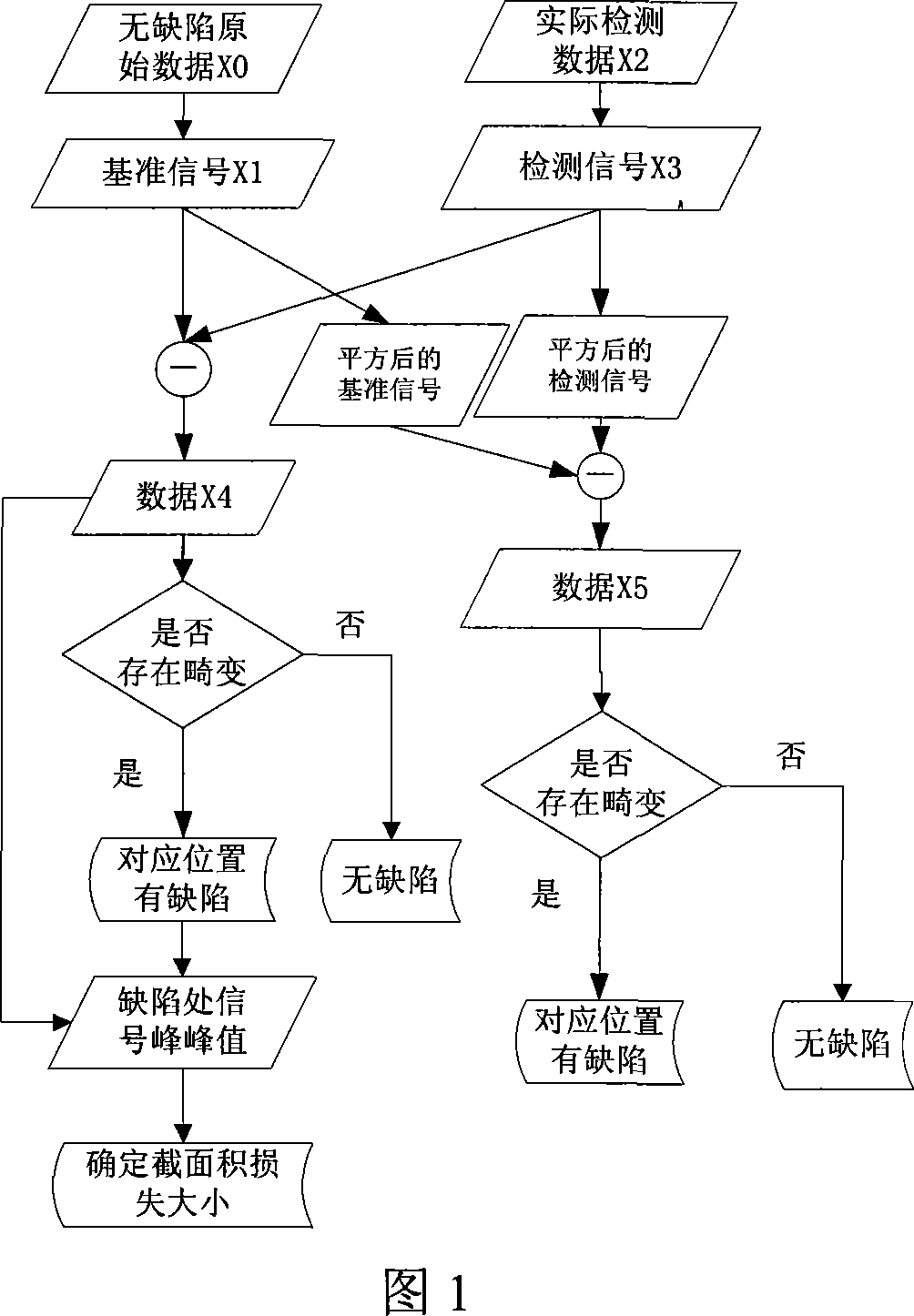

[0022] As shown in Figure 1, the inventive method comprises the following steps:

[0023] (1) The excitation unit and the receiving unit of the magnetostrictive guided wave sensor are respectively installed on the non-defective standard sample member, and the induced electrical signal of the receiving unit is collected, and the collection duration is T 0 , to obtain the measurement signal X of a set of non-defective standard samples 0 , where T 0 The value of is determined by the member length and detection range, such as according to the detection requirements, T 0 The value range can be between 2ms and 200ms.

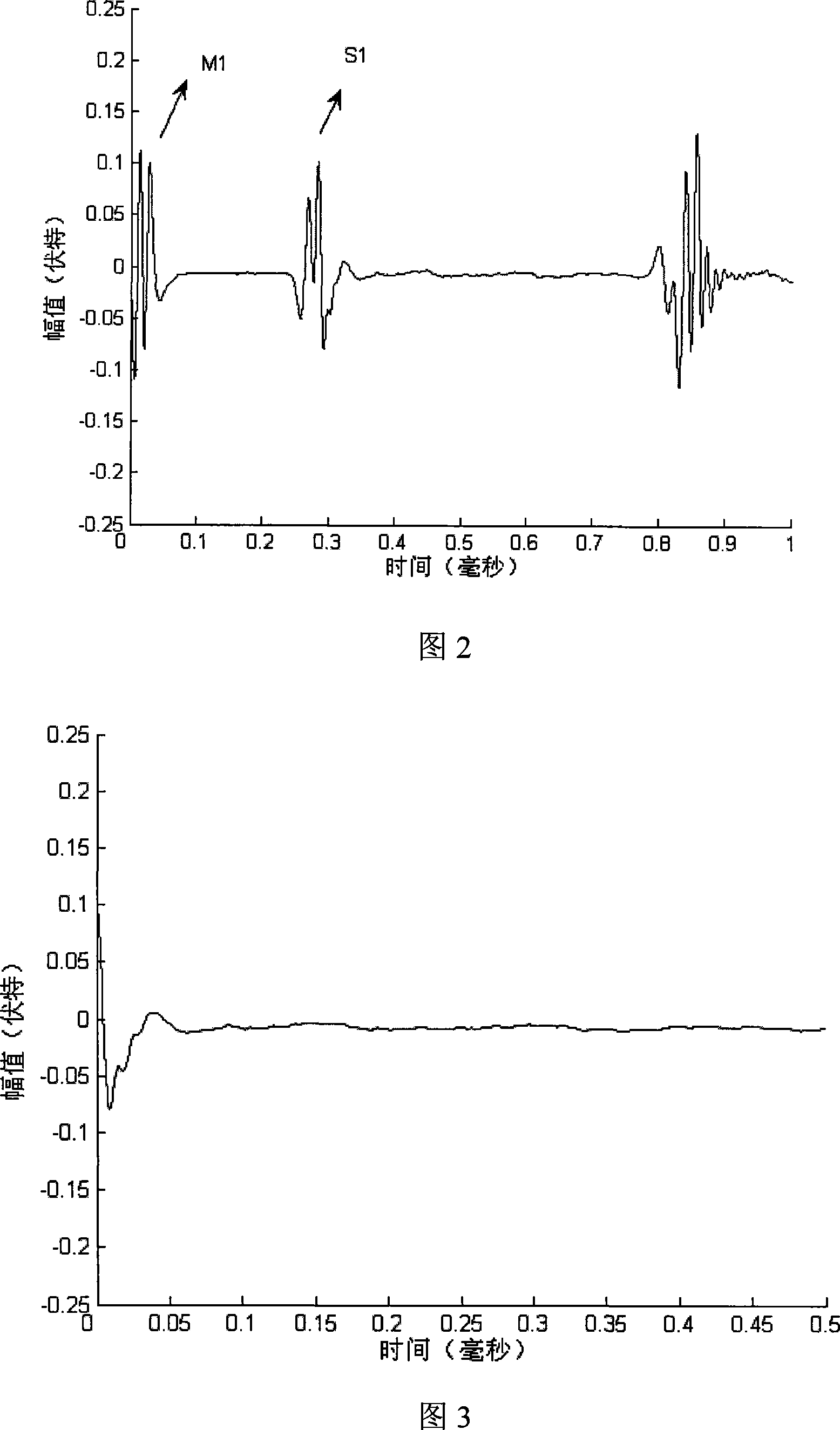

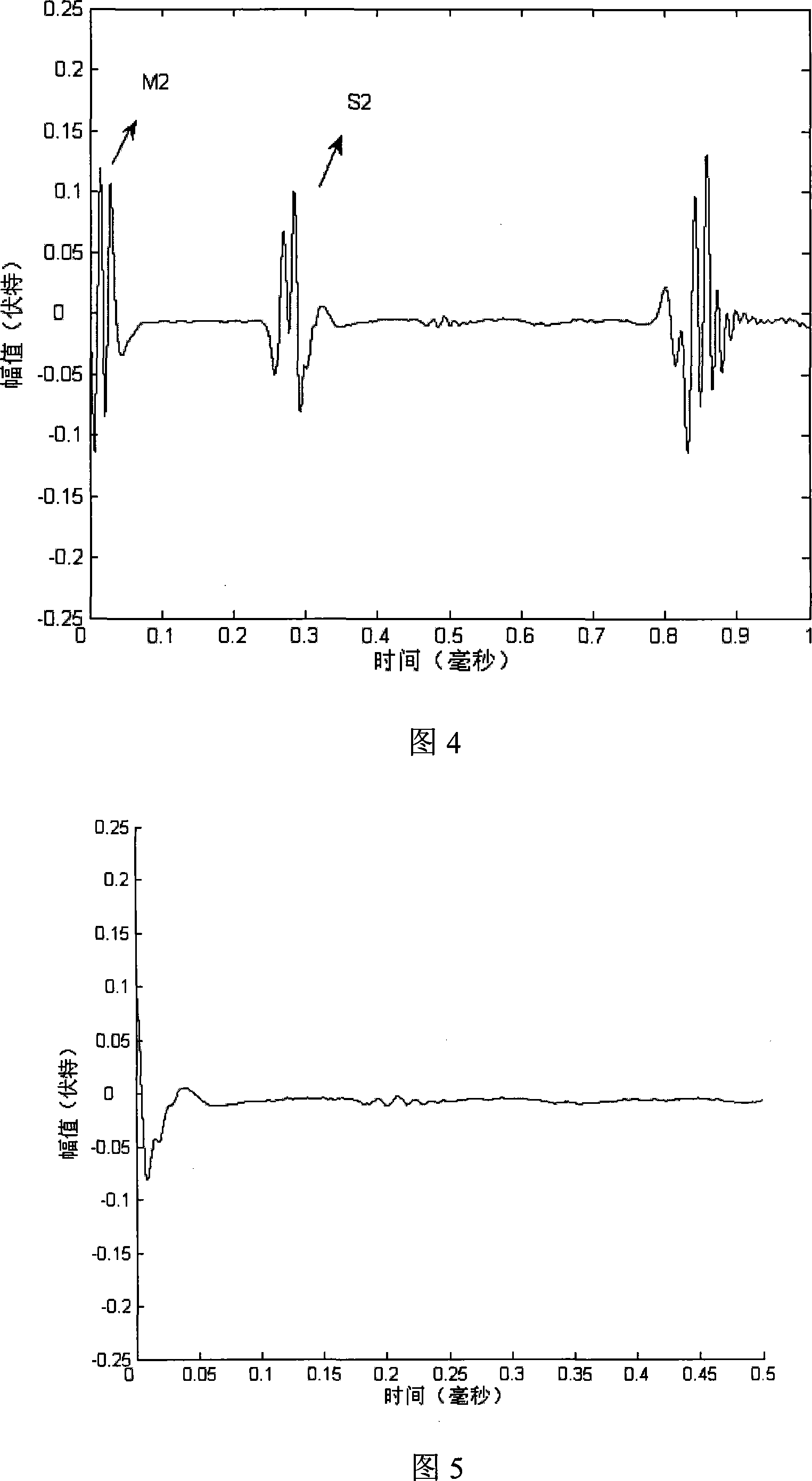

[0024] (2) Take the measurement signal X 0 The maximum value or minimum value of the induction signal of the guided wave passing through the receiving unit for the first time is used as the starting point of the data, and the interce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com