Roofing leak-proof structure sheaf and roofing leak-proof processing method for forming the same

A treatment method and a technology for structural layers, applied to roofs, roof coverings, and roofs using flat/curved panels, can solve problems such as unsatisfactory anti-leakage effects, cracks, and leakage, and achieve simple and convenient construction and low cost. Low, improve the effect of leakage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

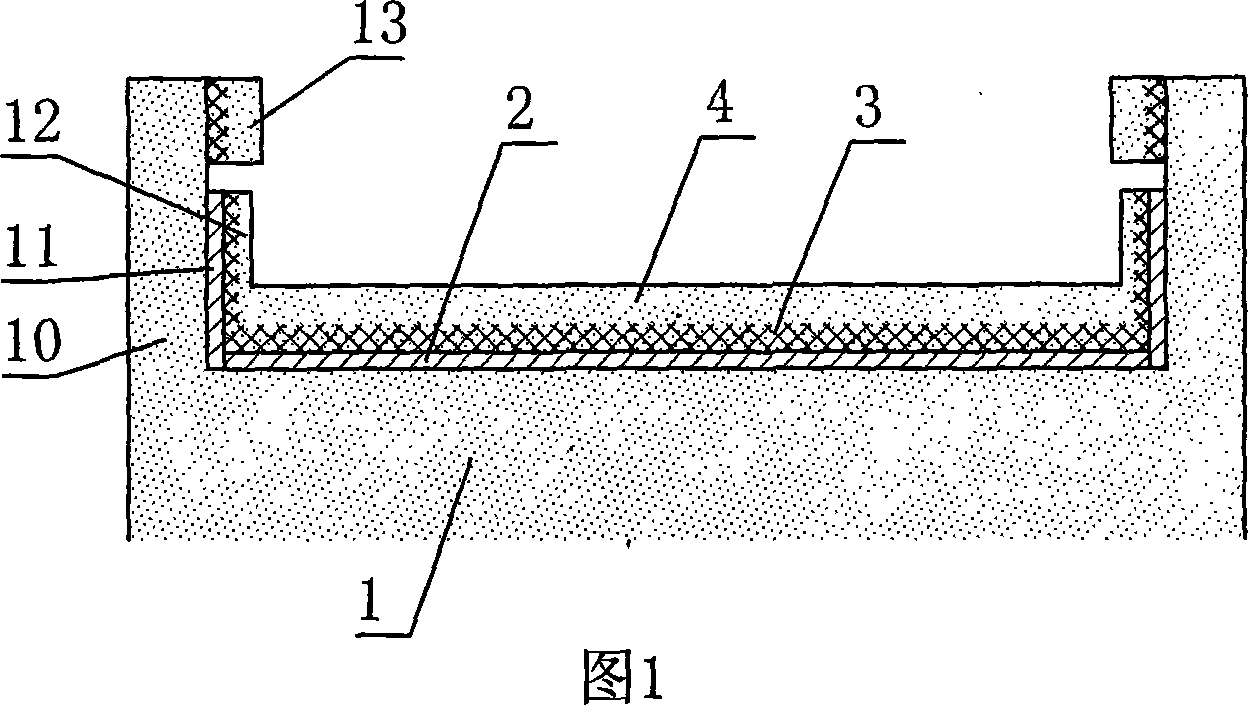

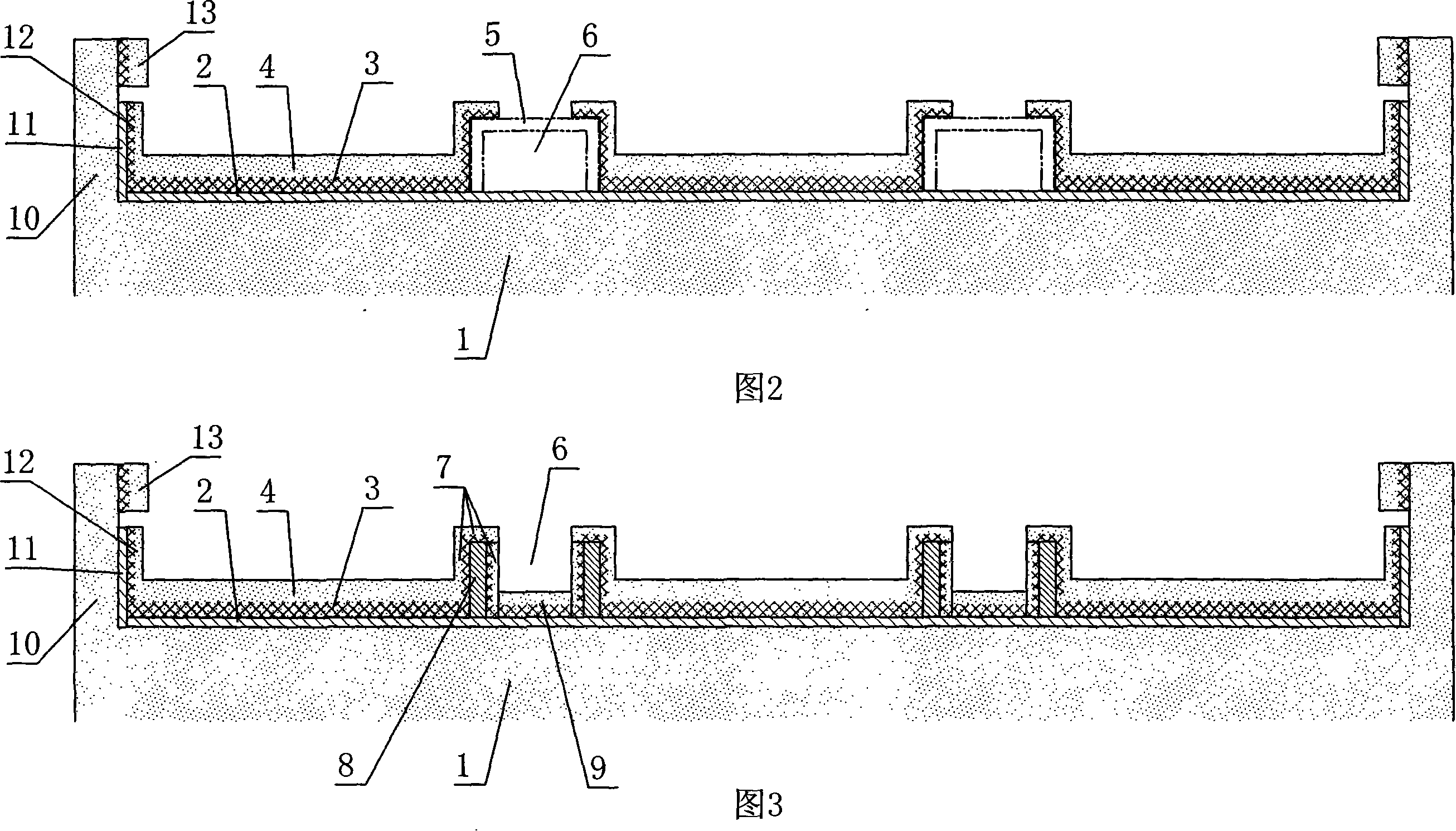

[0024] (1) As shown in Figure 1, a kind of roof leak-proof structure layer is characterized in that: it comprises the foam layer 2 that is covered on the cement board 1 top of roof, the reticular layer 3 that spreads on the foam layer top, and casts on A cement covering layer 4 that is poured integrally with the mesh layer above the mesh layer.

[0025] The cement covering layer is embedded with steel bars, and the mesh layer is steel wire or plastic or asbestos mesh layer.

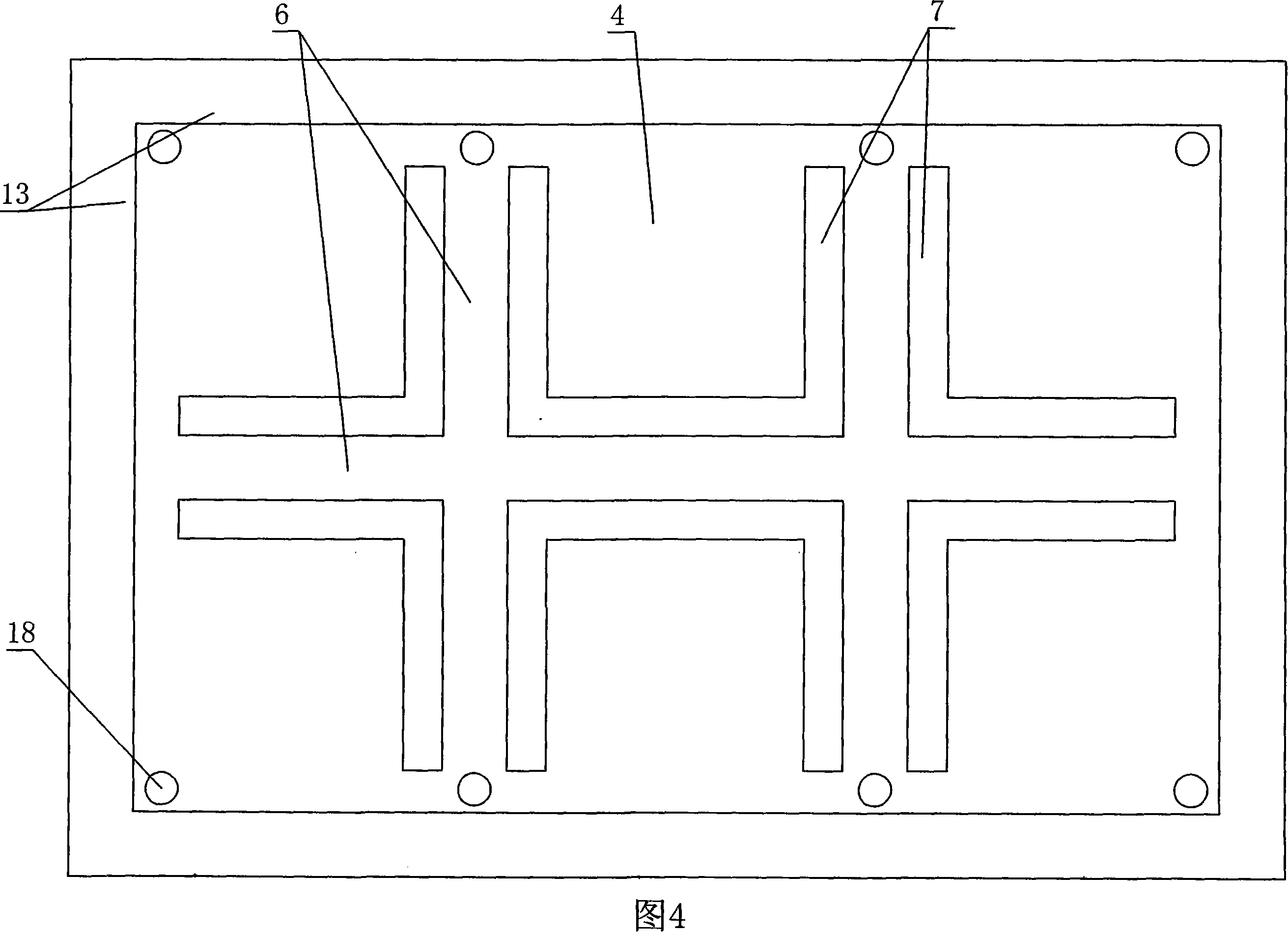

[0026] As shown in Fig. 3 and Fig. 4, the cement covering layer is provided with broken seams 6 at appropriate intervals, and the sides of the broken seams are respectively provided with inverted U-shaped cement grooves 7 with upper arches, the bottom facing upwards, and the mouth facing downwards. Plastic foam 8 is filled in the channel of the U-shaped cement tank, and the tank body of the inverted U-shaped cement tank is composed of an inner layer mesh layer and an outer layer cement covering layer inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com