Symmetrical intake and exhaust cam of three-cylinder gasoline engine

A gasoline engine, symmetrical technology, applied in the direction of valve details, valve driving devices, etc., can solve the problems of high material consumption, low lift curve full coefficient, affecting the stability of the valve mechanism, etc., to achieve a stable valve mechanism and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the drawings and examples.

[0029] The invention lies in that the cam profile designed with a group of optimized parameters can not only meet the requirements of the engine charging performance, but also ensure the stability of the gas distribution mechanism.

[0030] The cam profile of the present invention is mainly applied to a 1.0L three-cylinder gasoline engine adopting a four-valve cylinder head.

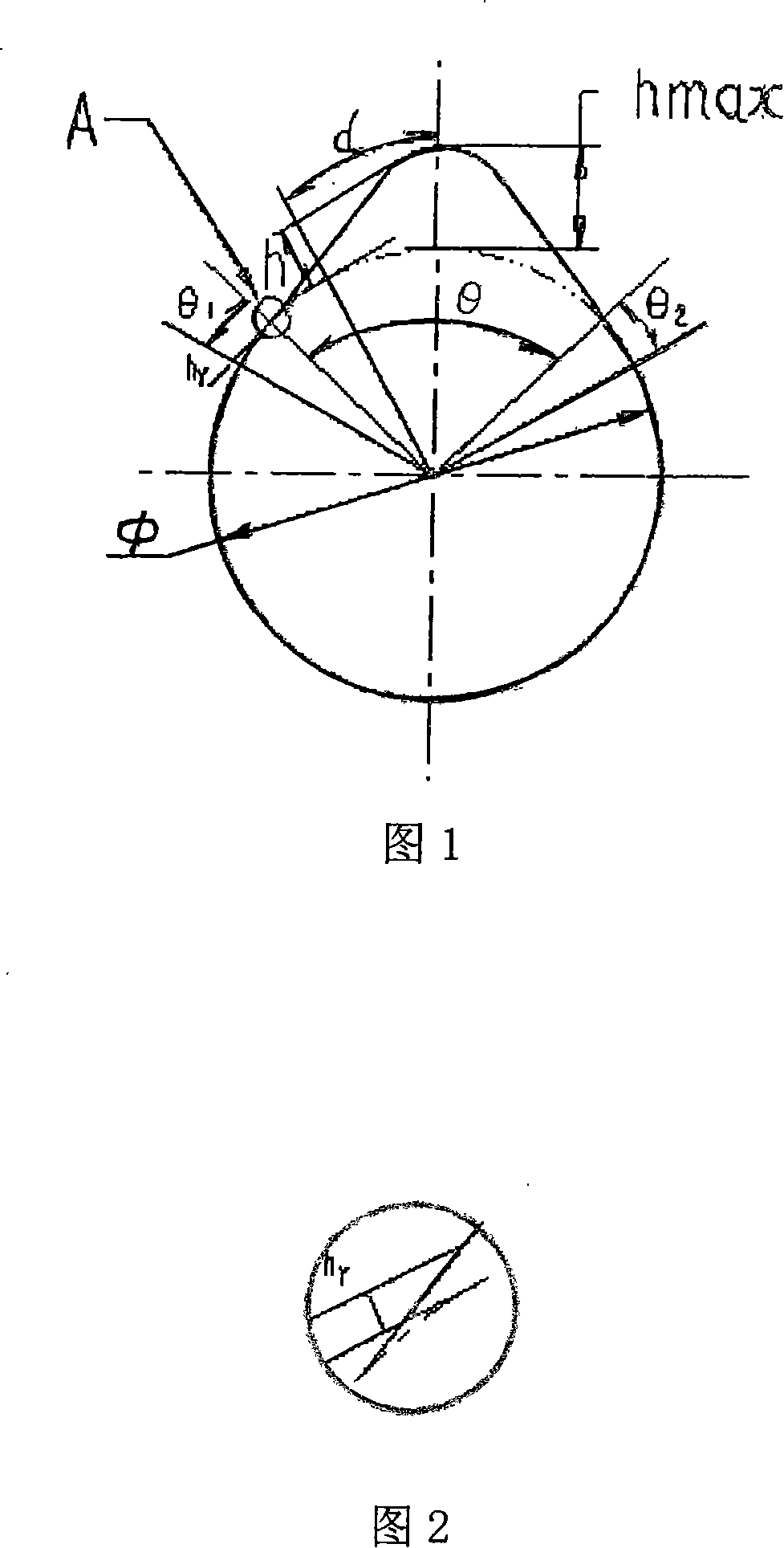

[0031] Fig. 1 is the cam profile of the intake and exhaust cam profile design of the three-cylinder gasoline engine of the present invention; Fig. 2 is an enlarged view of part A.

[0032] As shown in Fig. 1 and Fig. 2, the cam profile of the present invention consists of base circle, buffer section (θ 1 , θ 2 The arc segment corresponding to θ) and the working segment (the arc segment corresponding to θ) are composed of three segments.

[0033] Its working section adopts multiple dynamic equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com