Continuously-tuning full solid state ultraviolet laser

An ultraviolet laser, all-solid-state technology, used in lasers, laser parts, phonon exciters, etc., can solve problems such as complex procedures and affect the efficiency of instrument use, and achieve the effect of continuous tuning output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

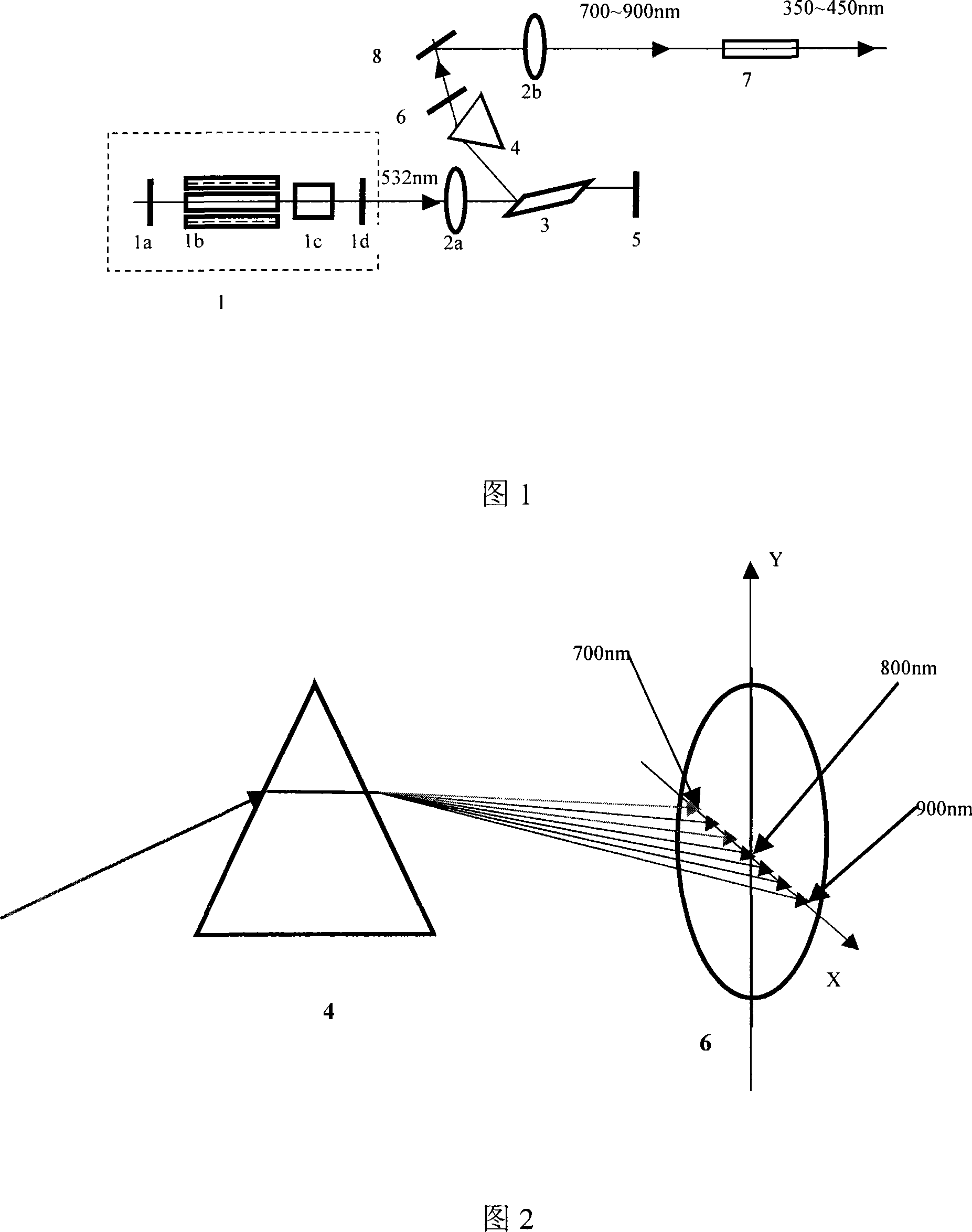

[0023] The coating bandwidth used in this embodiment is 100nm; the 532nm quasi-continuous Nd:YAG laser pumped by LD is used as the pumping source to pump the titanium sapphire solid-state laser; the tunable output of the fundamental frequency of 700-900nm is realized by tuning through a prism; and The continuously adjustable violet laser output with a wavelength of 350-450nm is realized by means of frequency conversion. The specific content is as follows:

[0024] 1) Use the 532nm quasi-continuous Nd:YAG 1b laser pumped by the existing LD (wavelength 808nm) as the pump source, and its maximum output average power can reach 25W; use the acousto-optic modulator 1c for frequency adjustment, and the modulation frequency is 5KHz . In order to improve the beam quality of 532nm to improve the pumping efficiency, a plano-convex unstable cavity structure is adopted in the experiment—the total reflection mirror (1a) is a plano-convex lens (R=600) coated with a 1.06um total reflection f...

Embodiment 2

[0029] The main difference between this embodiment and Embodiment 1 is that the polished surface of the output mirror 6 is divided into three parts along the X-axis and coated separately, which can realize continuous tuning output of 600-900 nm. The specific coating method is: from left to right along the X-axis, three types of film systems with a bandwidth of 100nm are plated sequentially—600-700nm, 700-800nm and 800-900nm. The left third of the polished surface of the output mirror 6 is coated with a partial reflection film of 600-700nm, the transmittance at 700nm is T=8%, and the transmittance decreases by 0.2% every 10nm, then the transmittance at 600nm is T=6 %. The middle third of the output mirror 6 is coated with a partial reflection film of 700-800nm, the transmittance at 700nm is T=8%, and the transmittance at 10nm increases by 1%, then the transmittance at 800nm is T=18%. The remaining one-third of the right side is coated with 800-900nm partial reflection film...

Embodiment 3

[0031] The main difference between this embodiment and Embodiment 1 is that the polished surface of the output mirror 6 is divided into four parts along the X-axis and coated separately, which can realize continuous tuning output of 600-1000 nm. The specific coating method is: from left to right along the X axis, four film systems with a bandwidth of 100nm are plated sequentially—600-700nm, 700-800nm, 800-900nm and 900-1000nm. A quarter of the polished surface of the output mirror 6 is coated with a partial reflection film of 600-700nm, the transmittance at 700nm is T=8%, and the transmittance decreases by 0.2% every 10nm, then the transmittance at 600nm is T=6%; A quarter of the output mirror 6 is coated with a partial reflection film of 700-800nm, the transmittance of 700nm is T=8%, and the transmittance of 10nm increases by 1%, then the transmittance of 800nm is T=18%; One of them is coated with a partial reflection film of 800-900nm, the transmittance at 800nm is T=18%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com