Cement type surface simple drawing mold

A drawing die, cement-type technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of complex processing and high material costs, and achieve the effects of simple production, material saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

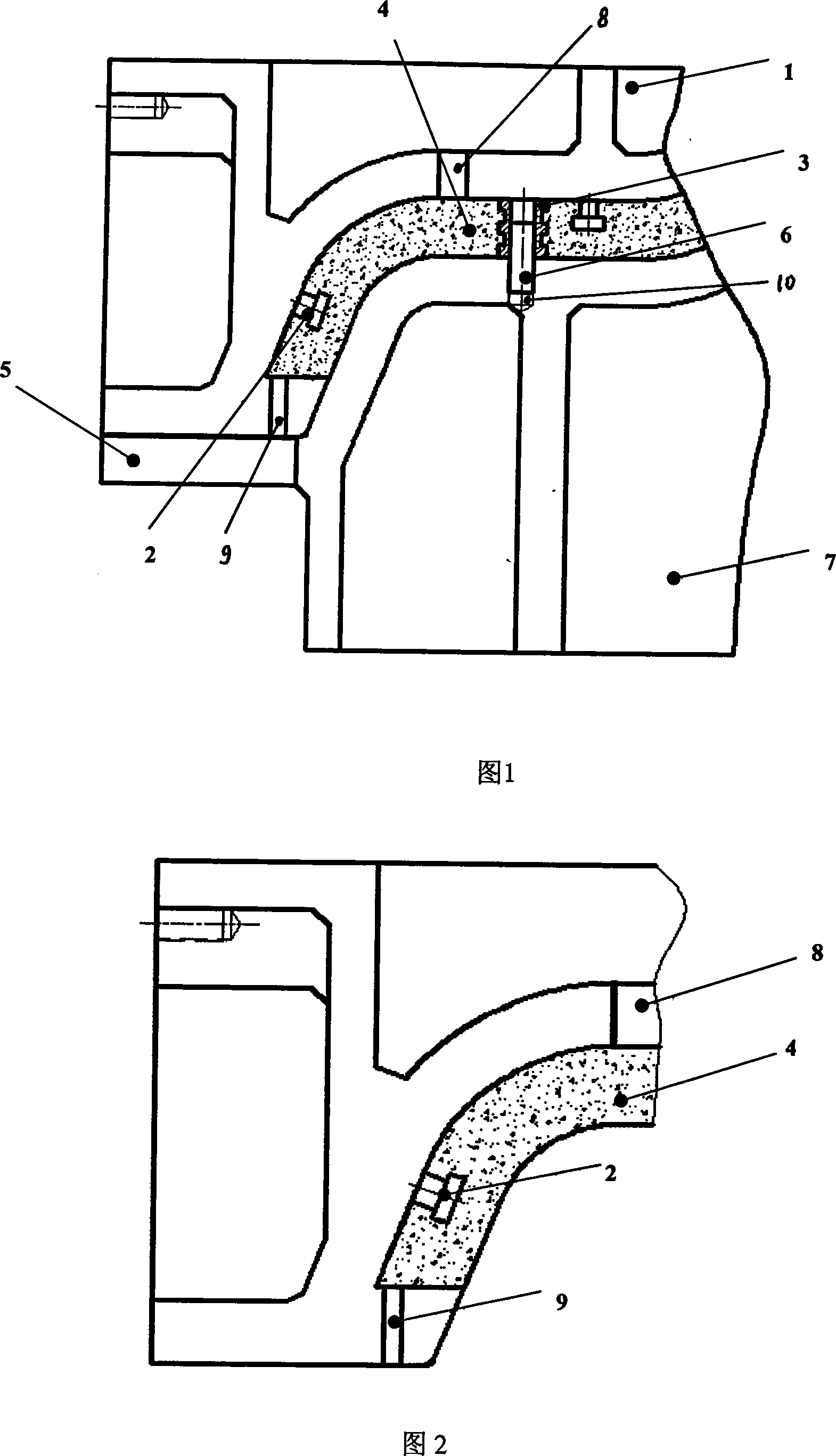

[0011] Referring to Fig. 1 and Fig. 2, the simple drawing mold for cement profile is composed of upper mold 1, cement surface fixing rod 2 cast on the upper mold, upper mold bushing 3, cement profile 4, blank holder 5, lower mold Counterdie pin 6 and lower die 7 form. The cement surface 4 is fixed on the upper mold 1 through the cement surface fixing rod 2 of the upper mold 1, the cement surface fixing rod 2 is cast on the upper mold 1, and the upper mold bushing 3 is embedded in the upper mold cement mold during the cement pouring process. In the surface 4, the lower mold counter-mold pin 6 is tightly fitted into the profile hole 10 of the lower mold 7. The cement profile 4 has vent holes for pouring at the parting surface of the upper mold, and a cement pouring port 8 is arranged on the bottom surface of the upper mold. When the upper die 1 works, press the blank holder 5 downwards, and after the upper die bushing 3 aligns with the lower die matching pin 6 of the lower die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com