Kinetic energy apparatus

A kinetic energy and buoy technology, applied in engine components, machines/engines, hydropower, etc., can solve problems such as unavailability, reduction in power generation, and inability to store 100% of kinetic energy power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

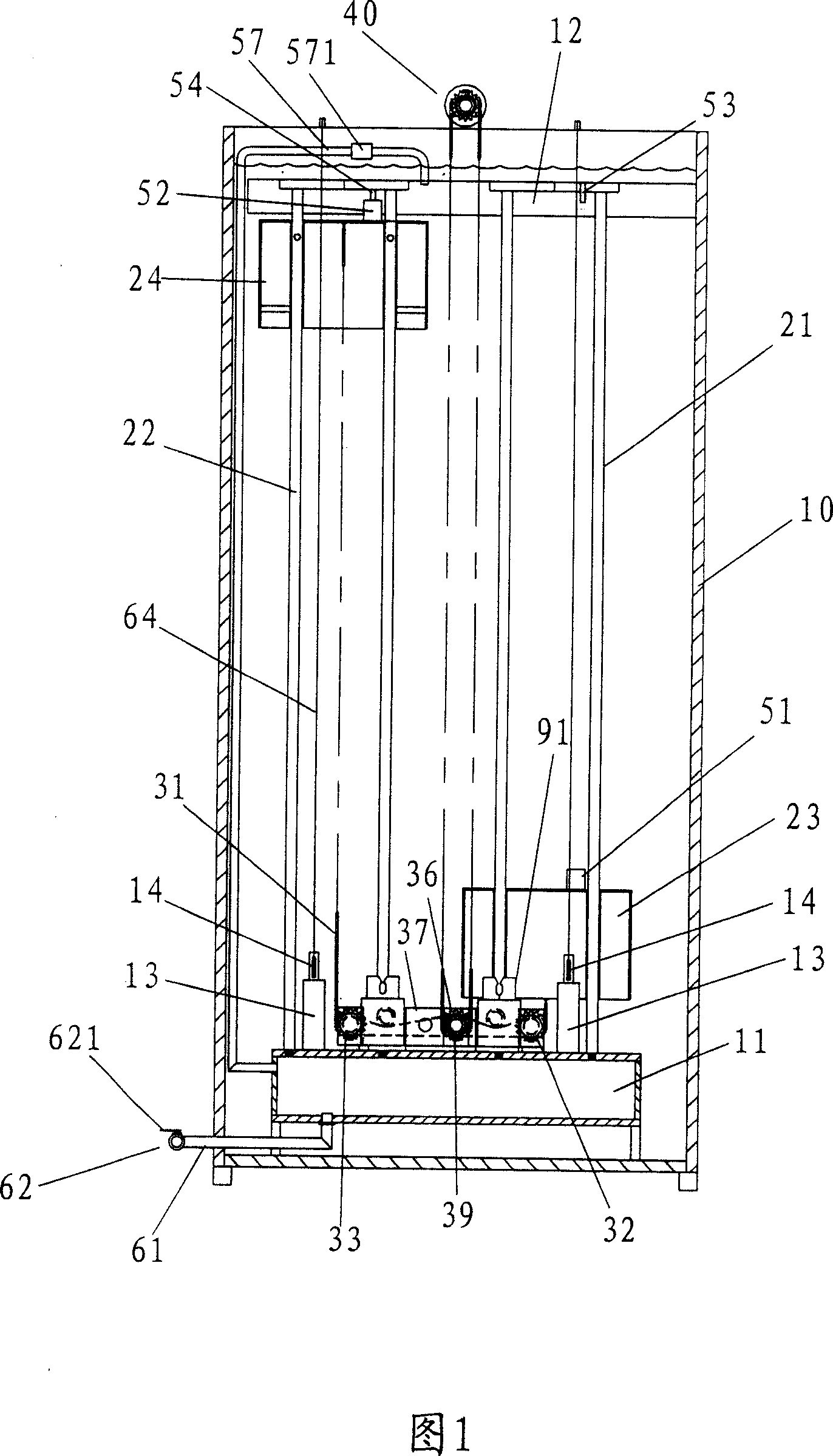

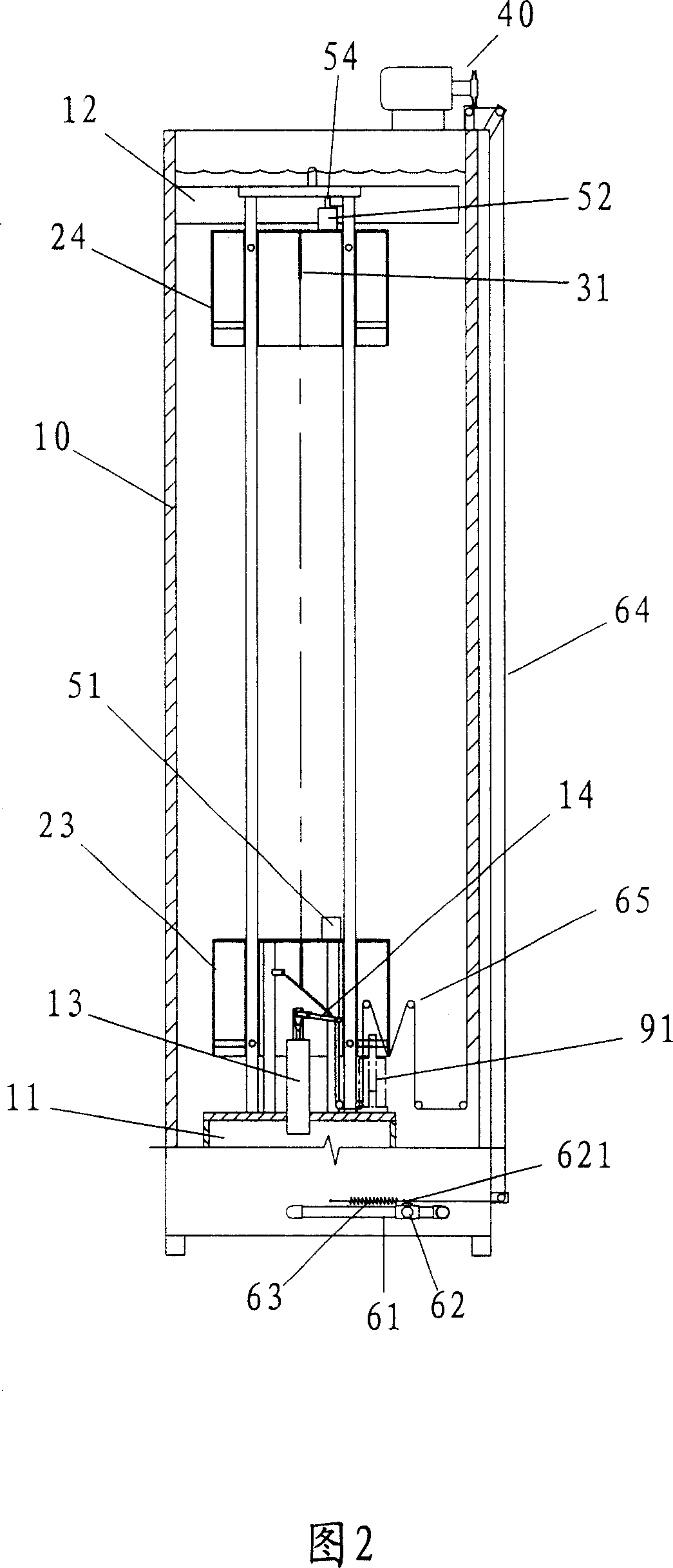

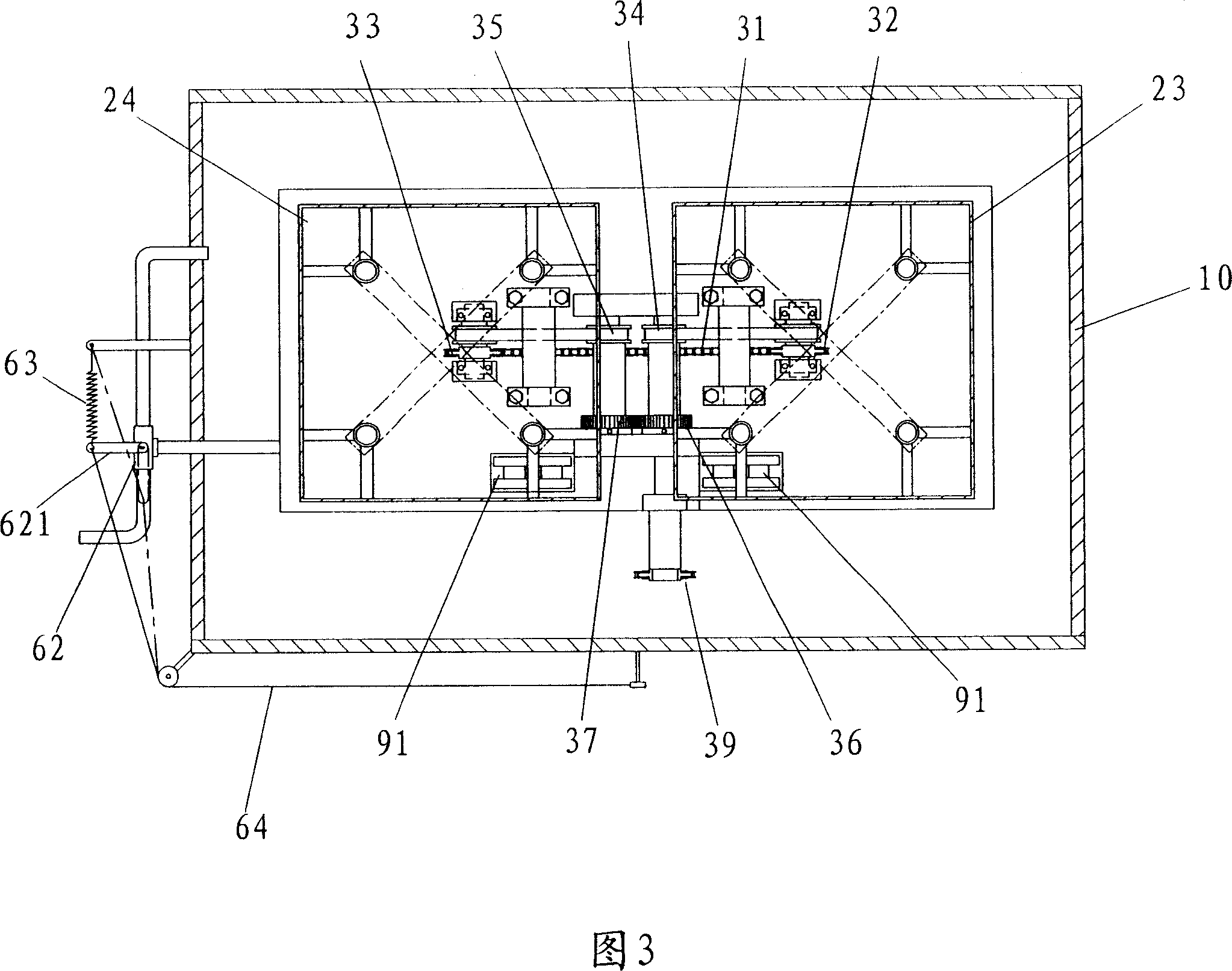

[0037] Please refer to shown in Fig. 1, 2, 3, the hydraulic type kinetic energy device of the present invention mainly comprises a water tank 10, and an air storage tank 11 is arranged at the bottom of the water tank 10, and a slide is arranged between the gas storage tank 11 and the air storage cover 12 at the top. Column group 21,22, is accommodated for two buoys 23,24, is connected with chain 31 between two buoys 23,24 and goes around two sprockets 32,33 on the gas storage tank 11, and two sprockets 32,33 are provided with One-way bearings, and the one-way bearings of the two sprockets 32,33 are arranged in reverse, so that the chain 31 can only drive the rotation of a single sprocket when sliding up and down; 321 , 331 drive two mutually meshing gears 36 , 37 with pulley sets 34 , 35 , one gear 36 is connected to an output shaft 38 , and the sprocket 39 of the output shaft 38 is linked to the generator set 40 .

[0038] The tops of the aforementioned buoys 23, 24 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com