Circumferential torque electrical power generating system

A power generation system and circular force technology, applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of resource consumption and environmental pollution, inconsistent energy saving and environmental protection, and narrow suitable range, and achieve high energy conversion efficiency and land occupation. Small area and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

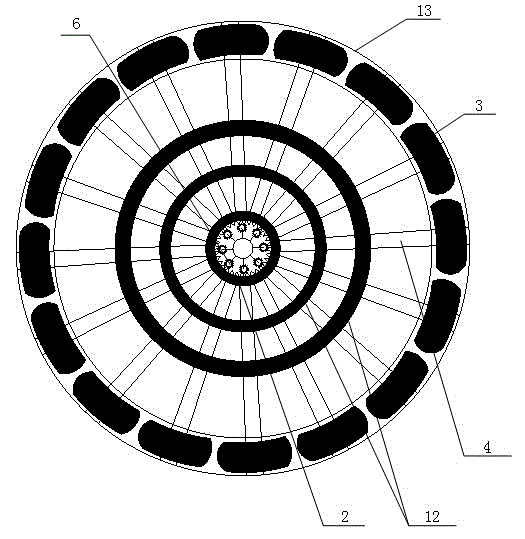

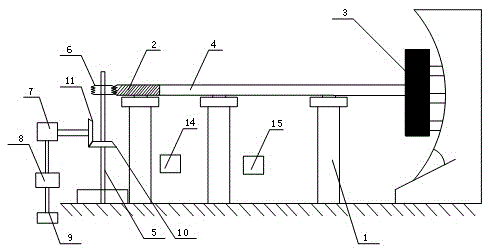

[0027] Such as figure 1 , 2 As shown, this embodiment provides a circular moment power generation system, the working principle of which is to convert the kinetic energy of the traction locomotive into electrical energy through a mechanical power generation device through the circular motion of the traction locomotive, so as to achieve the purpose of power generation, which is not only energy-saving and environmentally friendly, but also power generation Large quantity, small equipment footprint.

[0028] Specifically, the circular moment power generation system includes a circular traction track 13, a traction locomotive 3, a ring wheel 2, a rotating shaft 5, a drive gear 6, and a mechanical power generation system. Among them, the traction locomotive is set on the circular traction track, and performs circular motion along the circular traction track. In order to overcome the centrifugal force suffered by the traction locomotive when it makes circular motion, this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com