System with a superconducting cable

A technology of superconductivity and cables, applied in superconductivity devices, usage of superconductor elements, superconducting/high-conducting conductors, etc., can solve problems such as wear, terminal cable joint failure, electrical breakdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

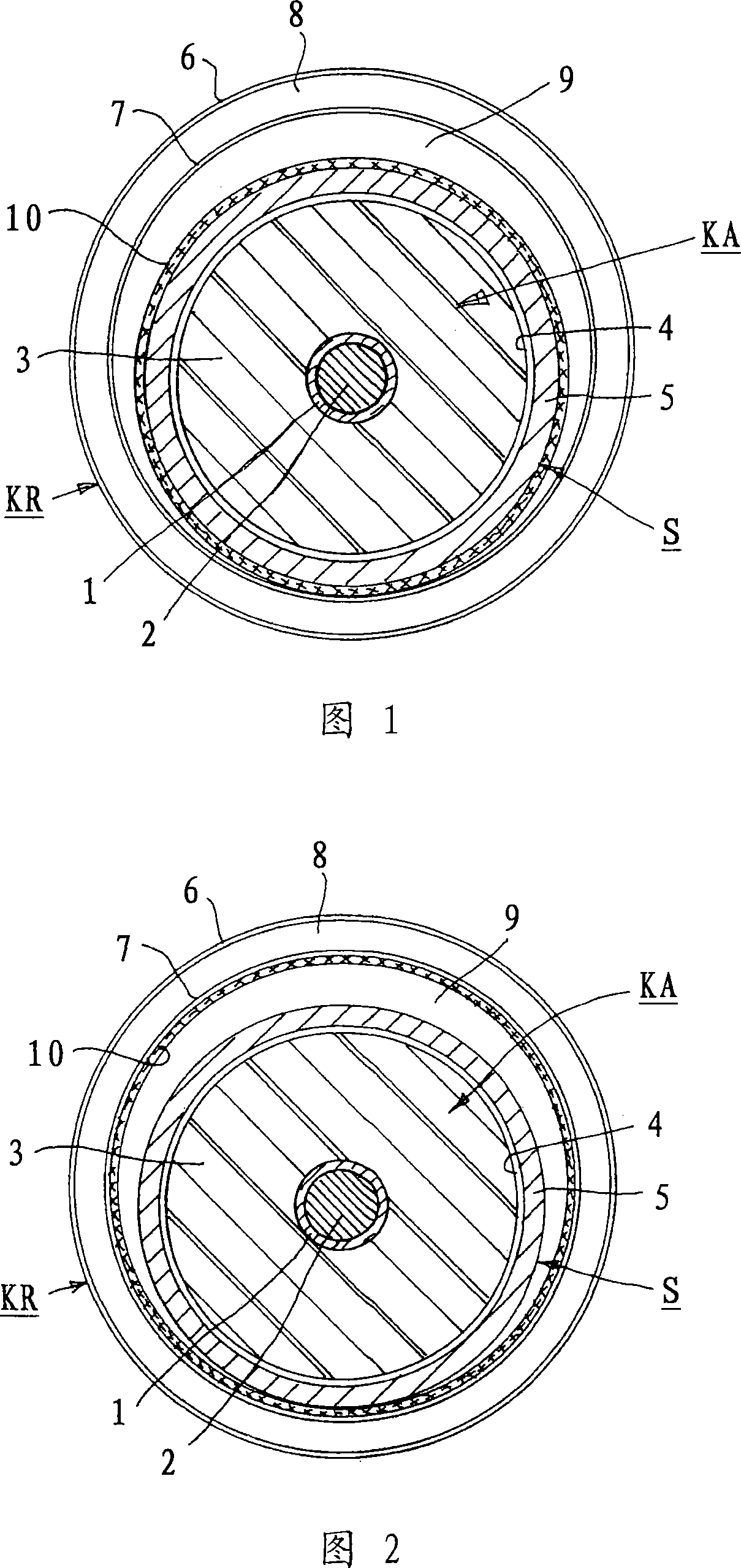

[0012] In the systems shown in FIGS. 1 and 2 , a superconducting cable KA with a cold dielectric is each arranged in a cryostat KR. The cable KA has an inner conductor 1 of superconducting material, which is laid around a metal core 2 made of a metal with good electrical conductivity, for example copper. The core wire 2 can be a core wire or a multi-strand wire. It can also be designed as a pipe, through which the coolant can be guided during system operation. The inner conductor 1 is surrounded by a dielectric 3 which consists of multiple layers of paper and / or paper laminated with polypropylene. On the dielectric 3 is arranged the shielding S of the cable KA, which consists of an inner superconducting part 4 surrounded by an outer part 5 of a metal with good electrical conductivity (below referred to as "conductor 5"). The conductor 5 is preferably made of copper.

[0013] The cryostat KR consists of two stainless steel tubes 6 and 7 which are separated from each other b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com