System and method for cooling a bog stream

A gas flow and refrigeration system technology, applied in the direction of refrigeration and liquefaction, liquefaction, cold treatment separation, etc., can solve the problem of large temperature difference in the middle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

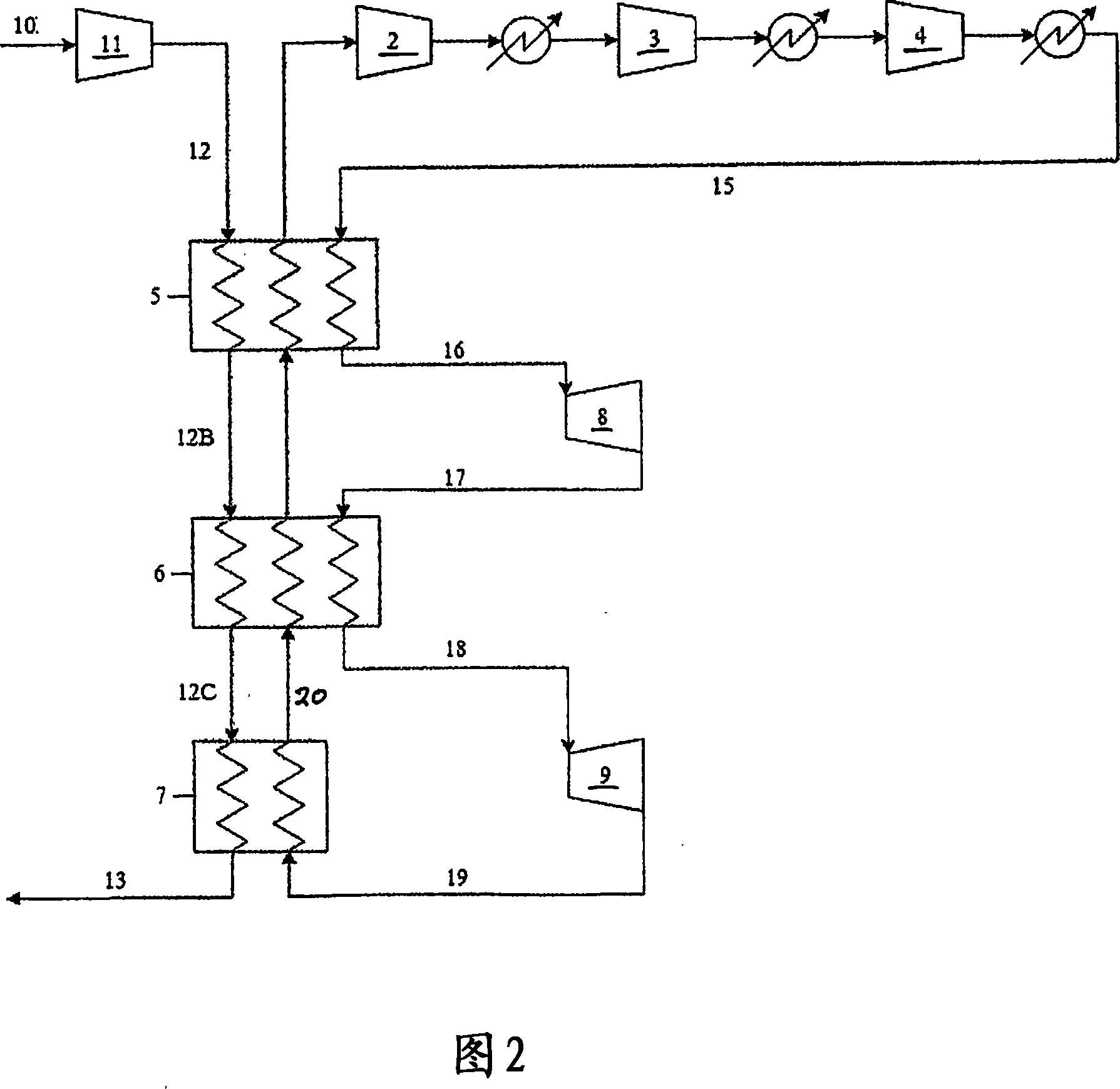

[0028] Implementing two expanders 8, 9 connected in series instead of parallel expanders can reduce the thermodynamic emissivity without splitting air flow Loss. A closed coolant (nitrogen) cycle would be similar to FIG. 2 , with boil-off gas from a storage tank (not shown) entering compressor 11 through line 10 . The compressed air stream 12 is sent through heat exchangers 5, 6, 7 and exchanges heat against a closed loop refrigeration system (the arrangement is commonly referred to as a "cold box"). While the cold box is being carefully adjusted, the stream 13 from the heat exchanger should be fully reliquefied.

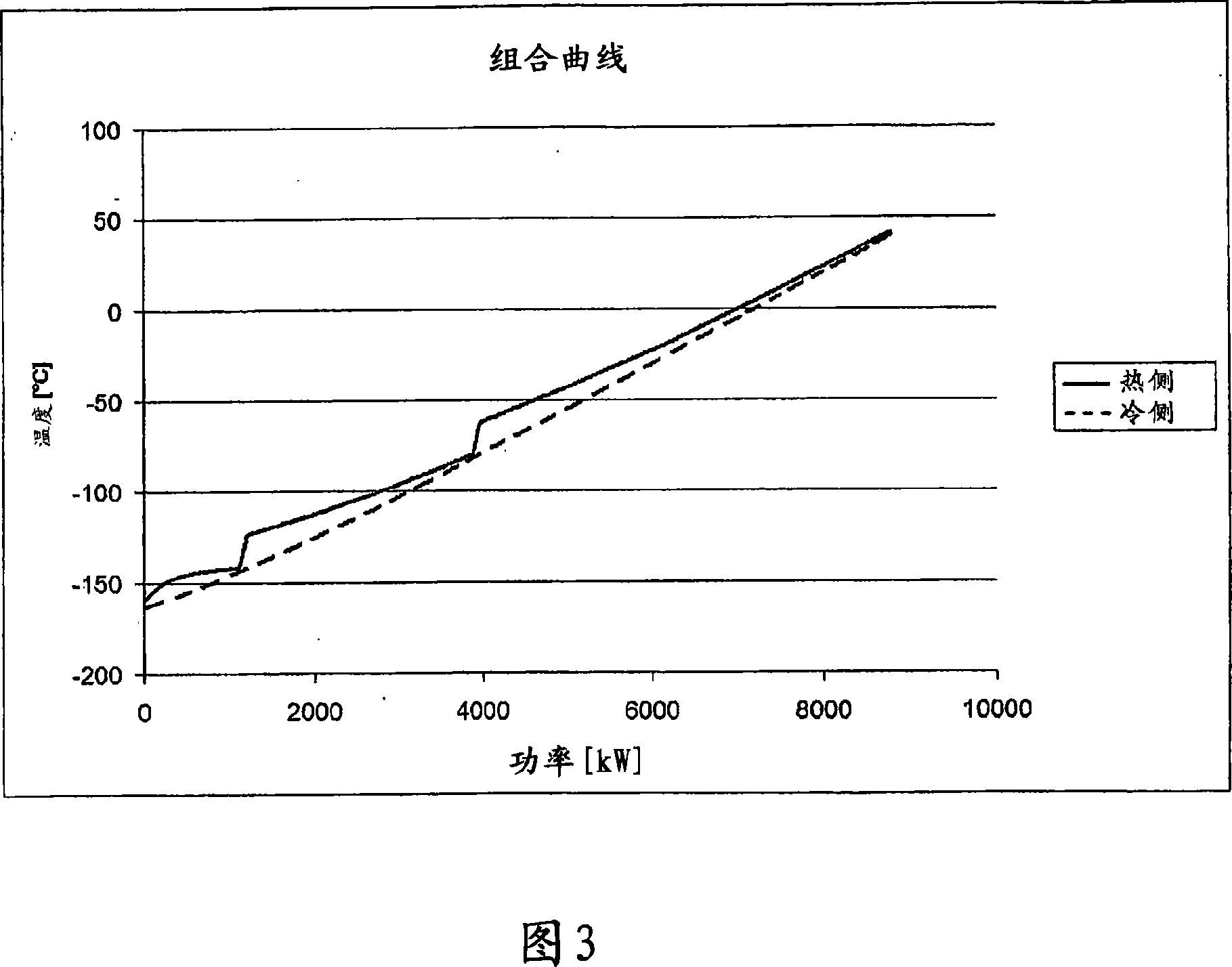

[0029] The choice of two expanders in series reduces the area of loss of thermodynamic emissivity by introducing a new local temperature pinch. The above can be seen when looking at the combined curve of Figure 3 showing representative data for two expanders 8, 9 cycles in series. Note that even though the cooling capacity and temperature / pressure levels remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com