Etching liquid supply device, etching device and etching method

A technology of etching device and supply device, which is applied in the direction of optics, instruments, electrical components, etc., can solve the problems of etching liquid changes, uneven etching of glass substrates, etc., and achieve the effect of uniform etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

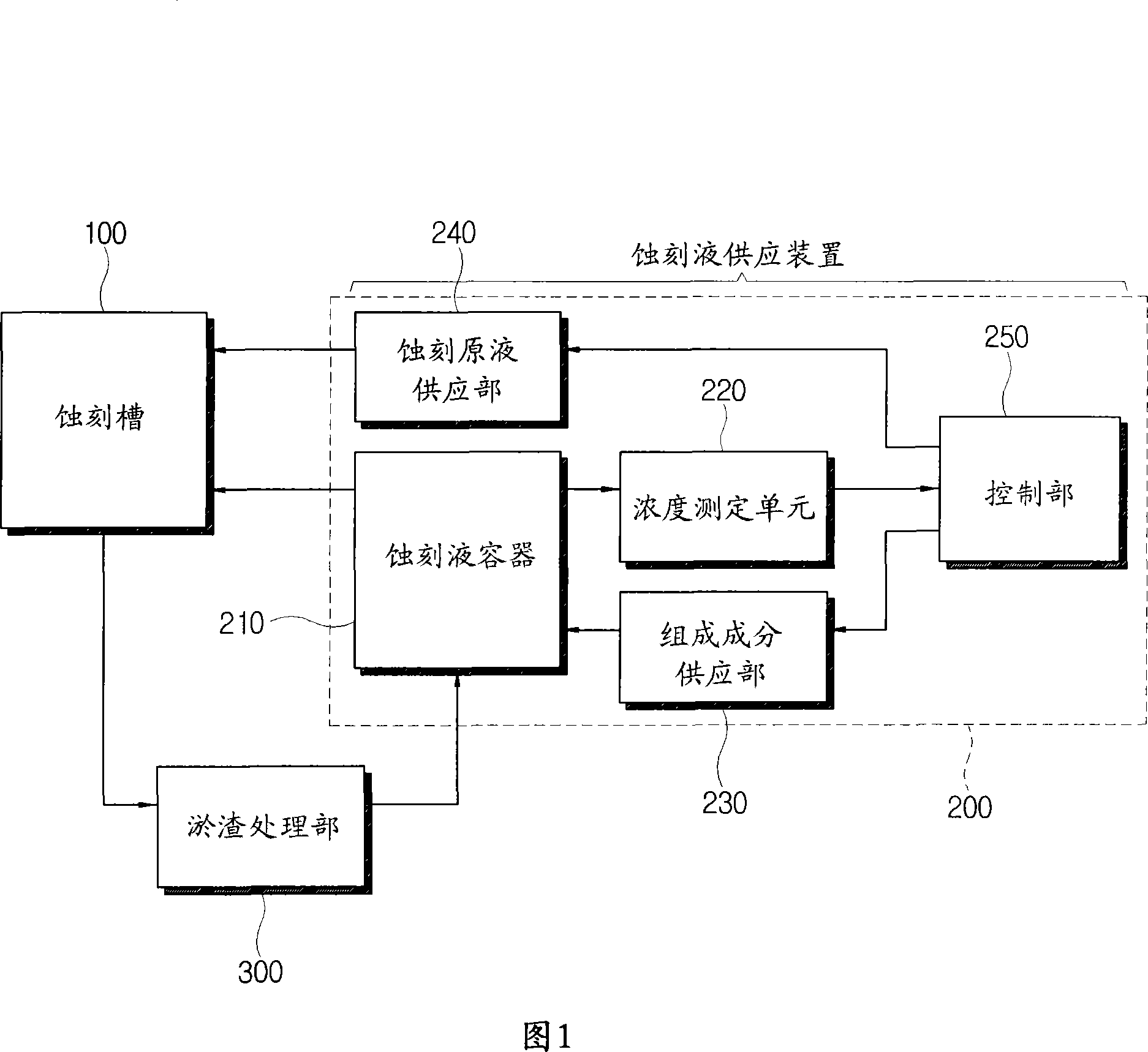

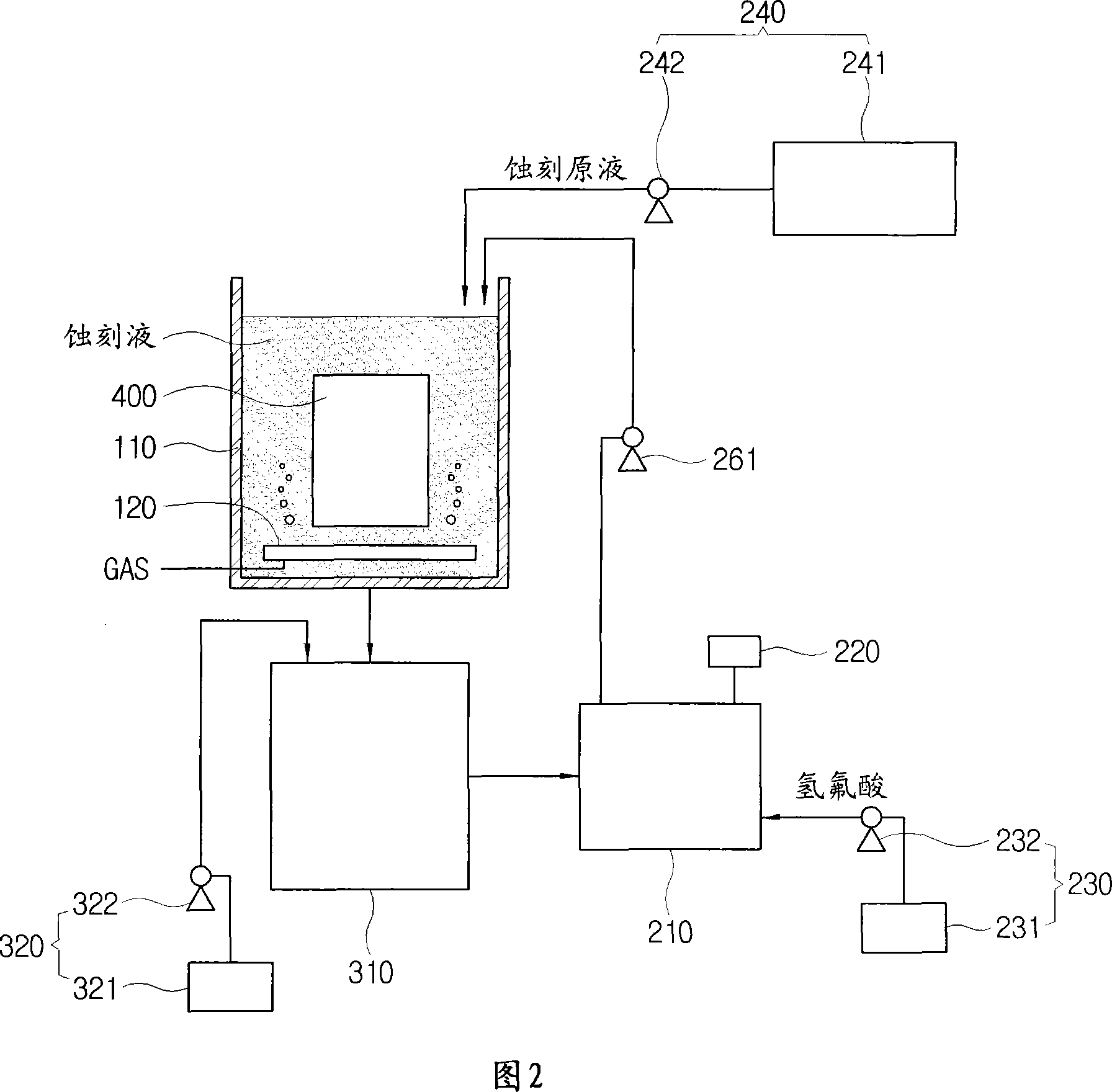

[0102] According to the third embodiment, the etching stock solution supply part 240 supplies the etching stock solution to the etching solution container 210 .

[0103] The etching solution container 210 supplies the etching solution into the etching tank 100 by mixing the etching solution returned from the etching tank 100 and the etching solution supplied from the etching solution supply part 240 . During this process, the concentrations of the constituents are compensated according to the concentration measuring unit 220 , the constituent supply unit 230 , and the control unit 250 .

[0104] Next, the etching device provided by the third embodiment of the present invention will be described in detail with reference to FIGS. 12 and 13 .

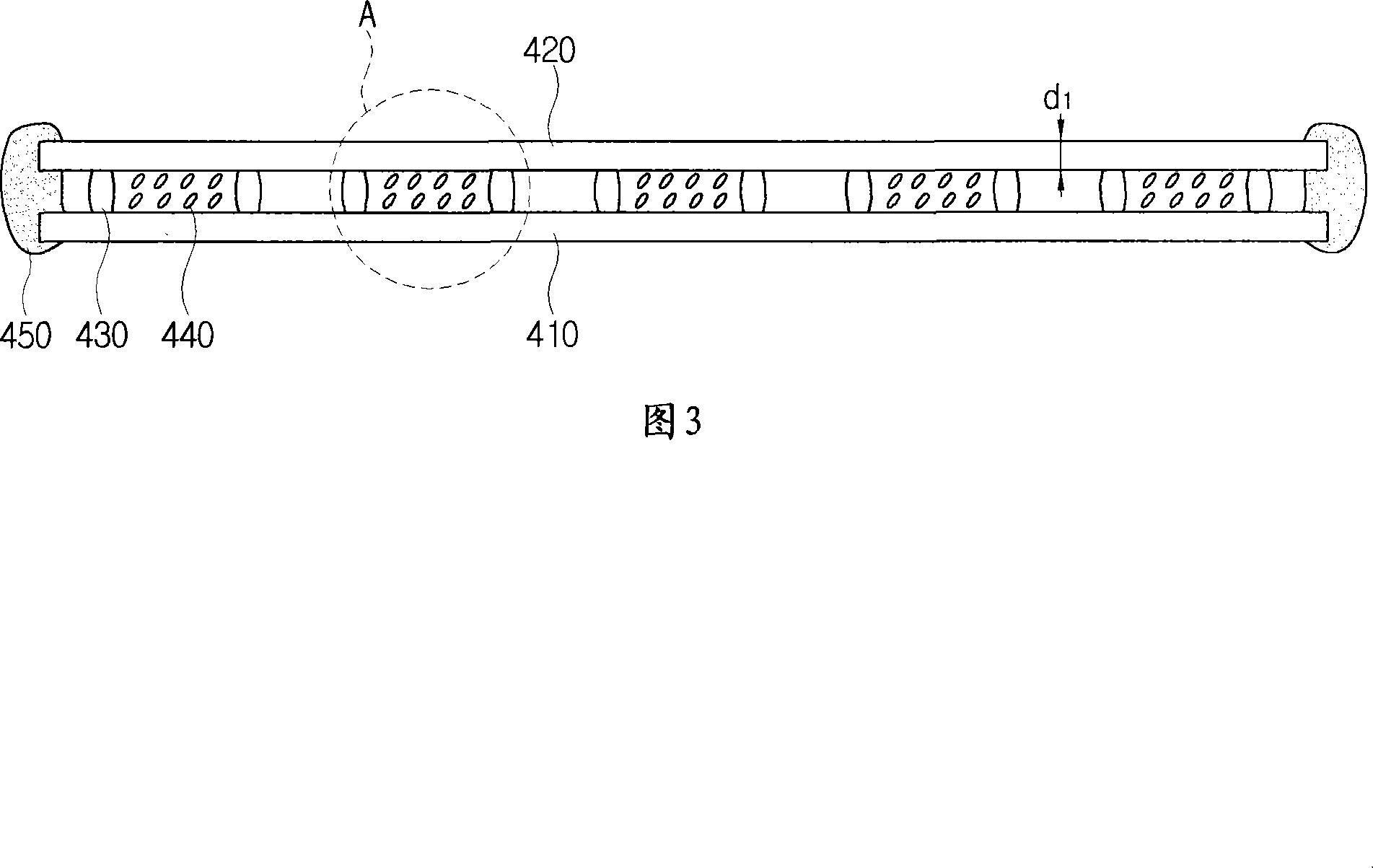

[0105] The etching tank 100 includes a tank body 110 , an etchant supply pipe 130 and a nozzle 140 .

[0106] As shown in FIGS. 12 and 13 , the etchant supply pipes 130 are provided at the upper and lower portions of the liquid crystal pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com