Plasma etching device

An etching device and plasma technology, applied in discharge tubes, climate sustainability, final product manufacturing, etc., can solve problems such as unstable discharge and uneven etching, and achieve uniform gas discharge, rich diversity, and engraving Eclipse effect ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

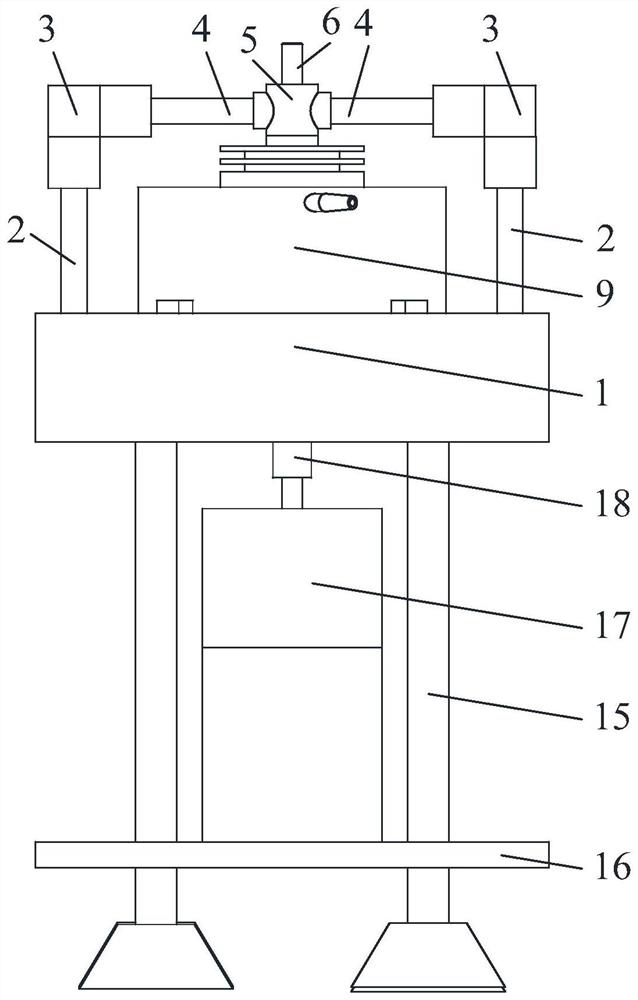

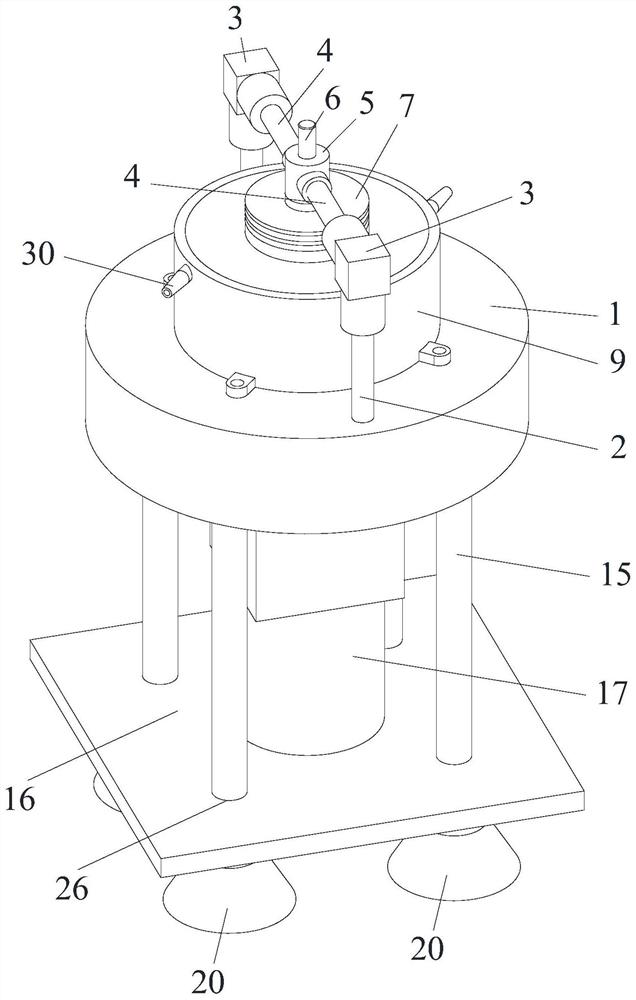

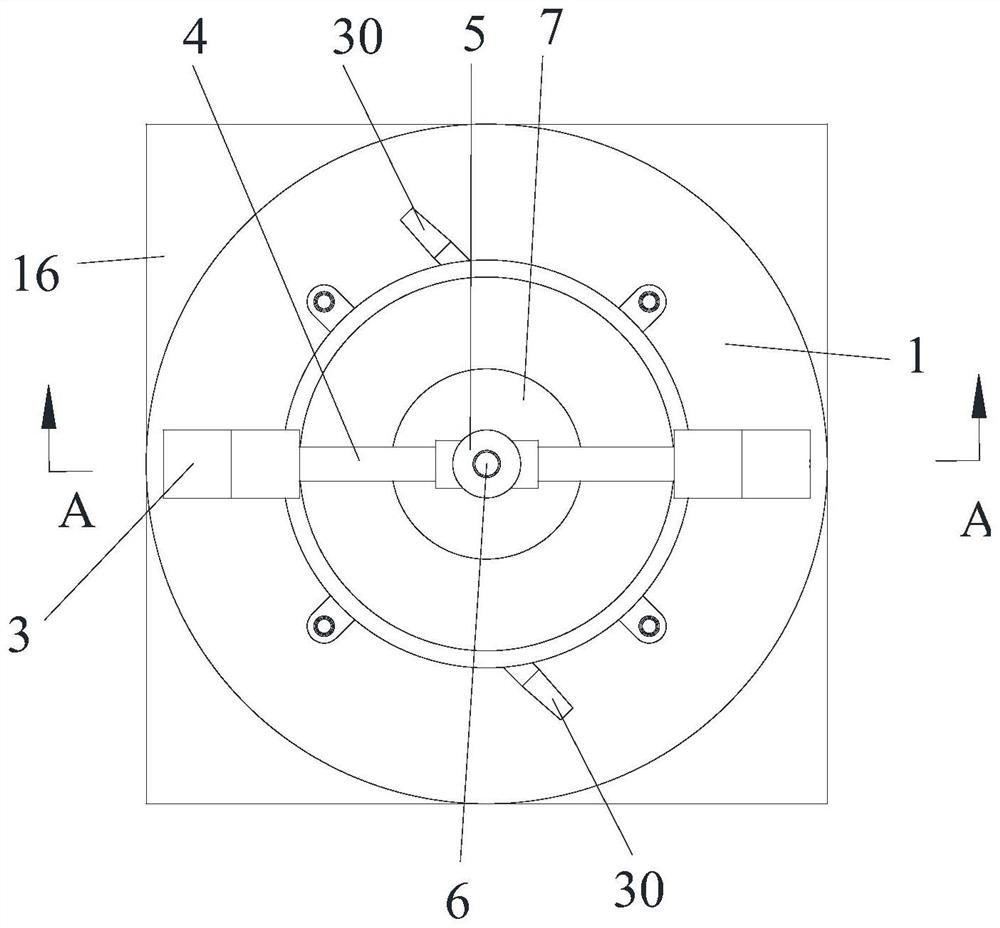

[0041] like Figure 1-7 As shown, a plasma etching apparatus described in this embodiment includes a first electrode 12 and a second electrode 7 arranged opposite to each other, and there is a space between the first electrode 12 and the second electrode 7 for placing the workpiece to be processed. The processing area 21 further includes a driving device 17, the first electrode 12 is provided with a tip 13 arranged in an array on the side close to the second electrode 7, and the tip 22 of the tip 13 points to the second electrode 7. The driving device 17 can drive the first electrode 12 to rotate.

[0042] In the plasma etching apparatus described in this embodiment, the first electrode 12 is provided with tips 13 arranged in an array on the side close to the second electrode 7, so that the first electrode 12 becomes a kind of An electrode with a tip array on the surface. Compared with the existing flat electrode, this electrode has many more tips 13 with large surface curvat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com