A kind of wet etching equipment

A wet etching and equipment technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems that the etching solution cannot be cleaned in time and effectively, the uniformity of the etching solution is different, and the etching of the substrate is uneven. Achieve the effect of simple structure, uniform etching effect and good stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

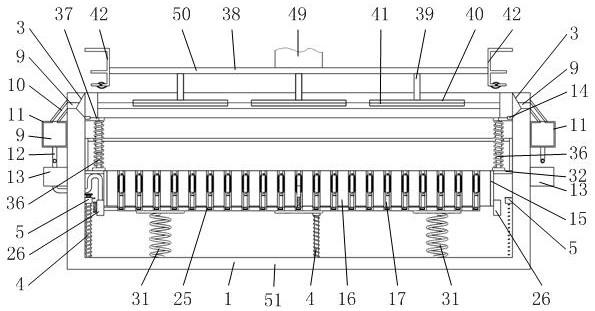

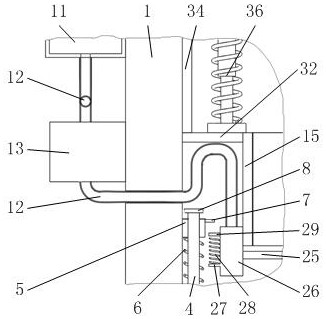

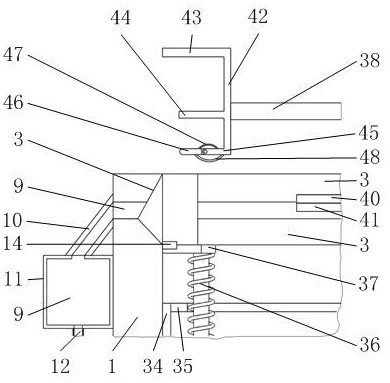

[0029] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0030] Such as figure 1 As shown, it includes an etching mechanism 51 and a dipping mechanism 50, wherein the dipping mechanism 50 driven by the mechanical arm 49 drives a number of etching substrates 41 evenly installed thereon to perform synchronous and uniform etching in the etching solution in the etching mechanism 51; The etching mechanism 51 quickly and effectively cleans and recovers the etching solution remaining on the etched substrate 41 , and at the same time, with the cooperation of the dipping mechanism 50 , uniformizes the concentration of the etching solution and makes the level of the etching solution level quickly.

[0031] Such as Figure 5 , 7 , 10, the etchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com