Shielding assembly and electrolytic device using shielding assembly

A component and electrolyte technology, applied in electrolysis process, electrolysis components, removal of conductive materials by chemical/electrolytic methods, etc., can solve the problem of edge effect affecting etching effect, etc., and achieve uniform etching effect and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

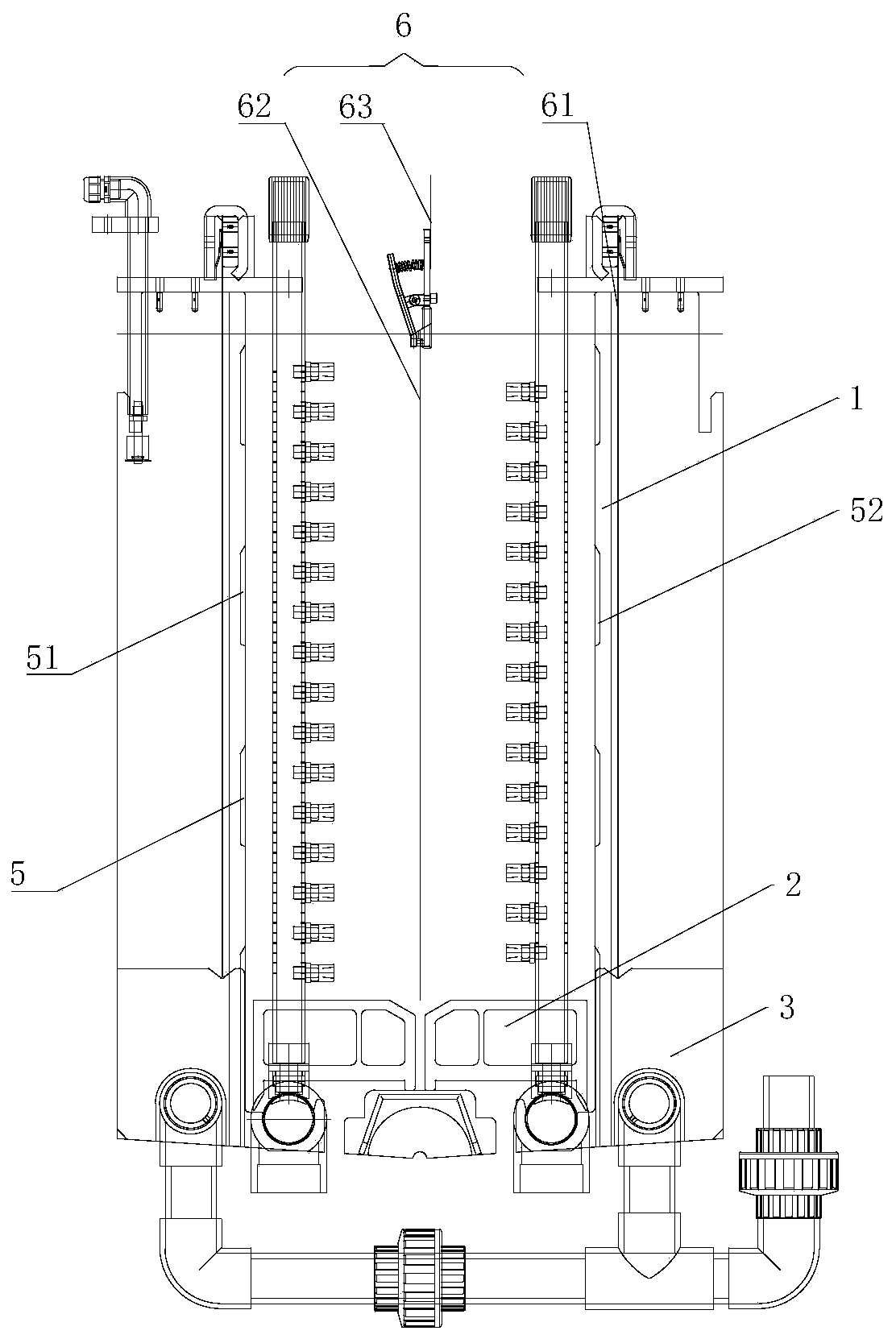

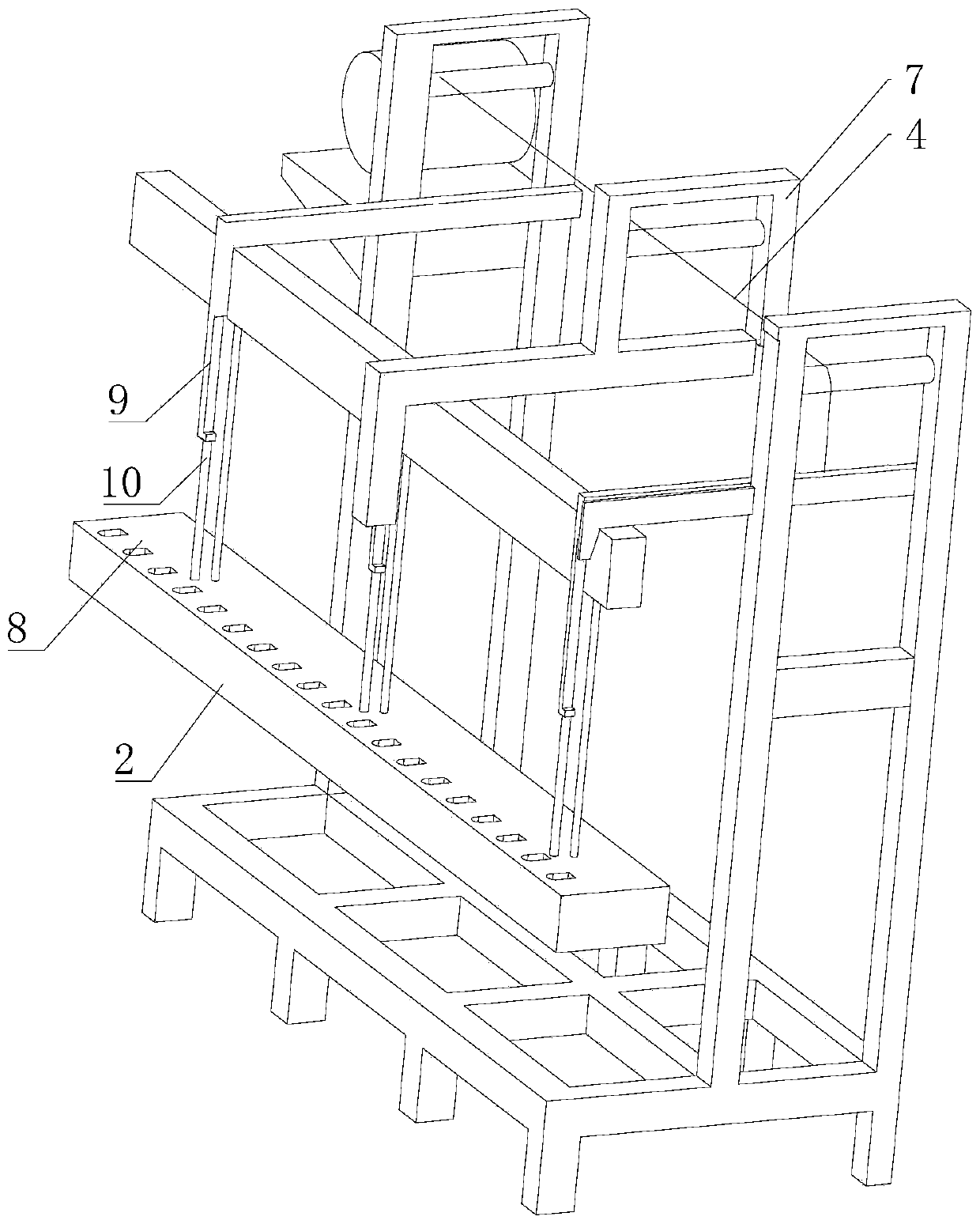

[0047] The present invention describes an electrolysis device, such as Figure 4 As shown, it comprises electrolytic cell 6, cathode part 61 and workpiece 62 to be etched that stretch into the electrolytic solution in electrolytic tank 6; The tank 6 is soaked in the electrolyte, and the piece to be etched 62 is conductively connected with the anode 63 to realize the conductive communication with the electrolyte.

[0048] Both the cathode part 61 and the part to be etched 62 are submerged in the electrolytic solution. After energization, the positive ions on the part to be etched 62 are oxidized and electrolyzed to attach to the cathode part 61. The part to be etched 62 in this embodiment is a PCB board. Electrolysis transfers the exposed copper on the surface layer of the PCB to the cathode member 61 , thereby electrolytically etching the exposed copper layer on the PCB to form the required circuit.

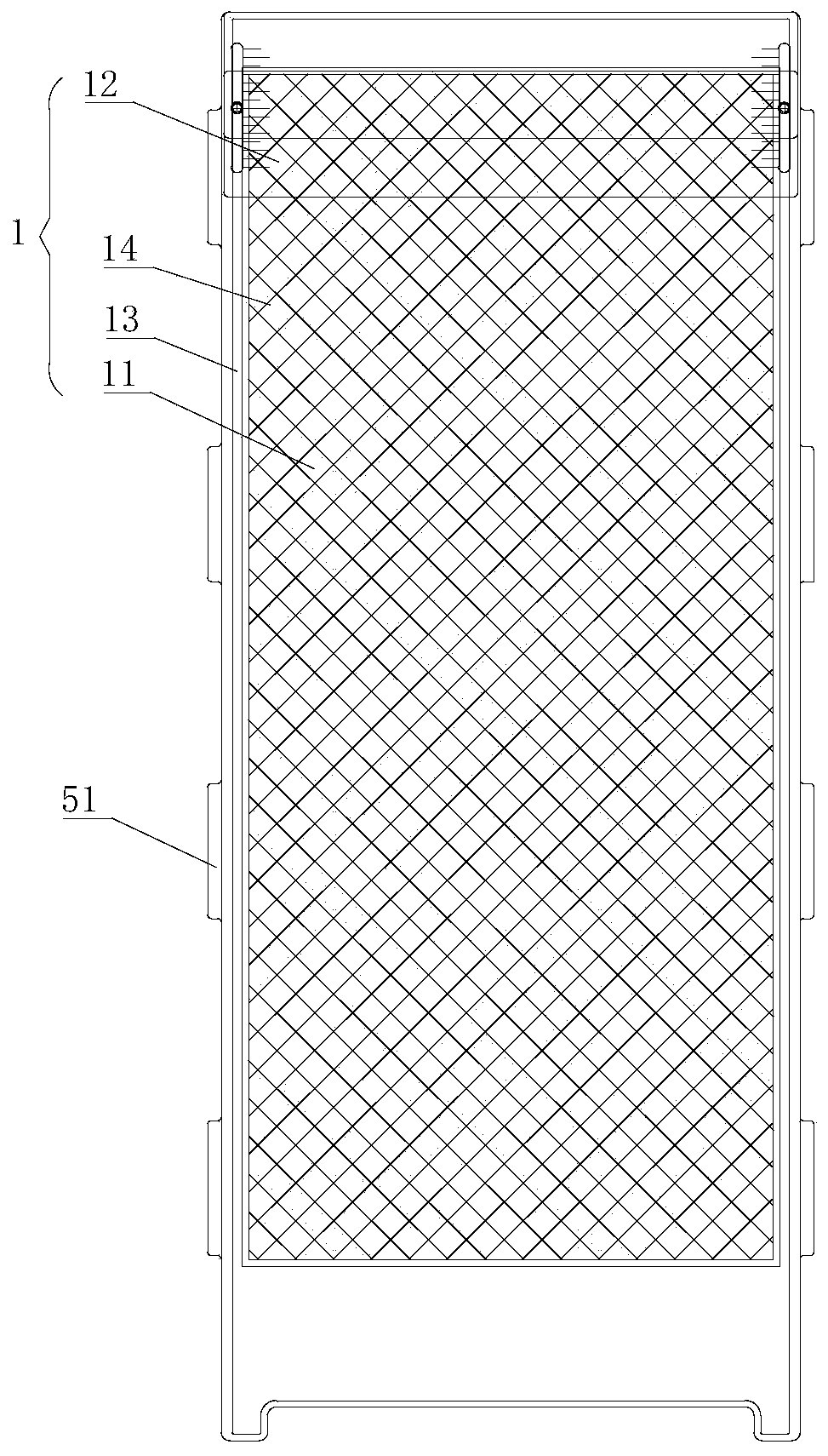

[0049] In this embodiment, there is also a shielding assembly disposed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com