Superconductive cable and DC power transmission using the superconductive cable

一种超导电缆、超导导体的技术,应用在DC传输系统领域,能够解决电流大、温度过度上升、AC损耗大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

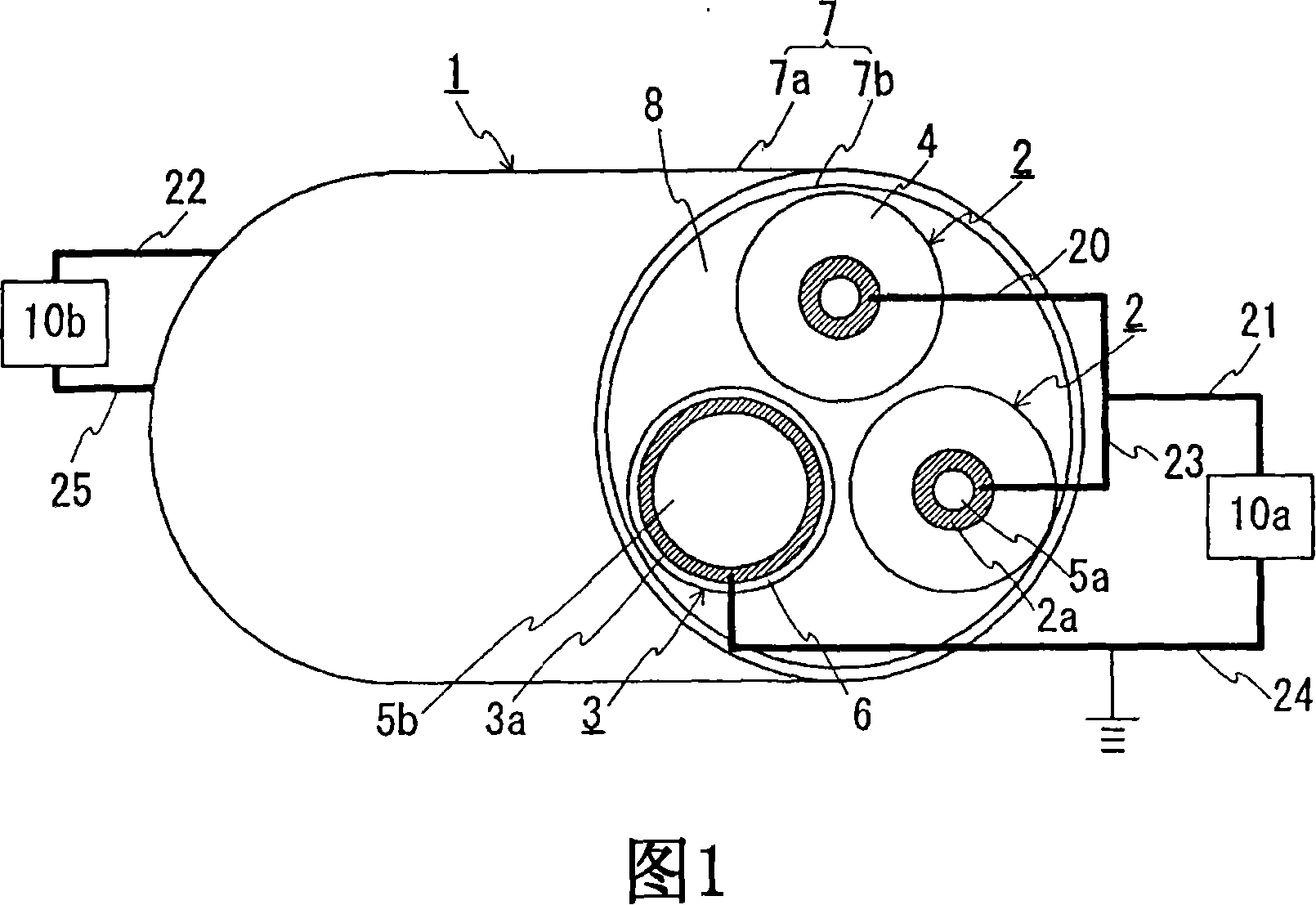

[0096] FIG. 1 is a schematic diagram showing a state in which a DC transmission line for unipolar transmission is constructed by using the superconducting cable of the present invention. In the following drawings, the same symbols denote the same components. The superconducting cable 1 is formed by twisting together two types of cores (two first cores 2 and one second core 3 ) having different structures and housing the twisted cores in a heat insulating tube 7 . More specifically, each first core 2 has a first superconducting layer 2a composed of a superconducting material at the inner peripheral side of the insulating layer 4 without a layer composed of a superconducting material at the outer peripheral side of the insulating layer 4 . The second core 3 is provided with a core part 5b at the central part side, a second superconducting layer 3a composed of a superconducting material is provided at the outer peripheral side of the core part 5b, and is not provided at the cent...

example 2

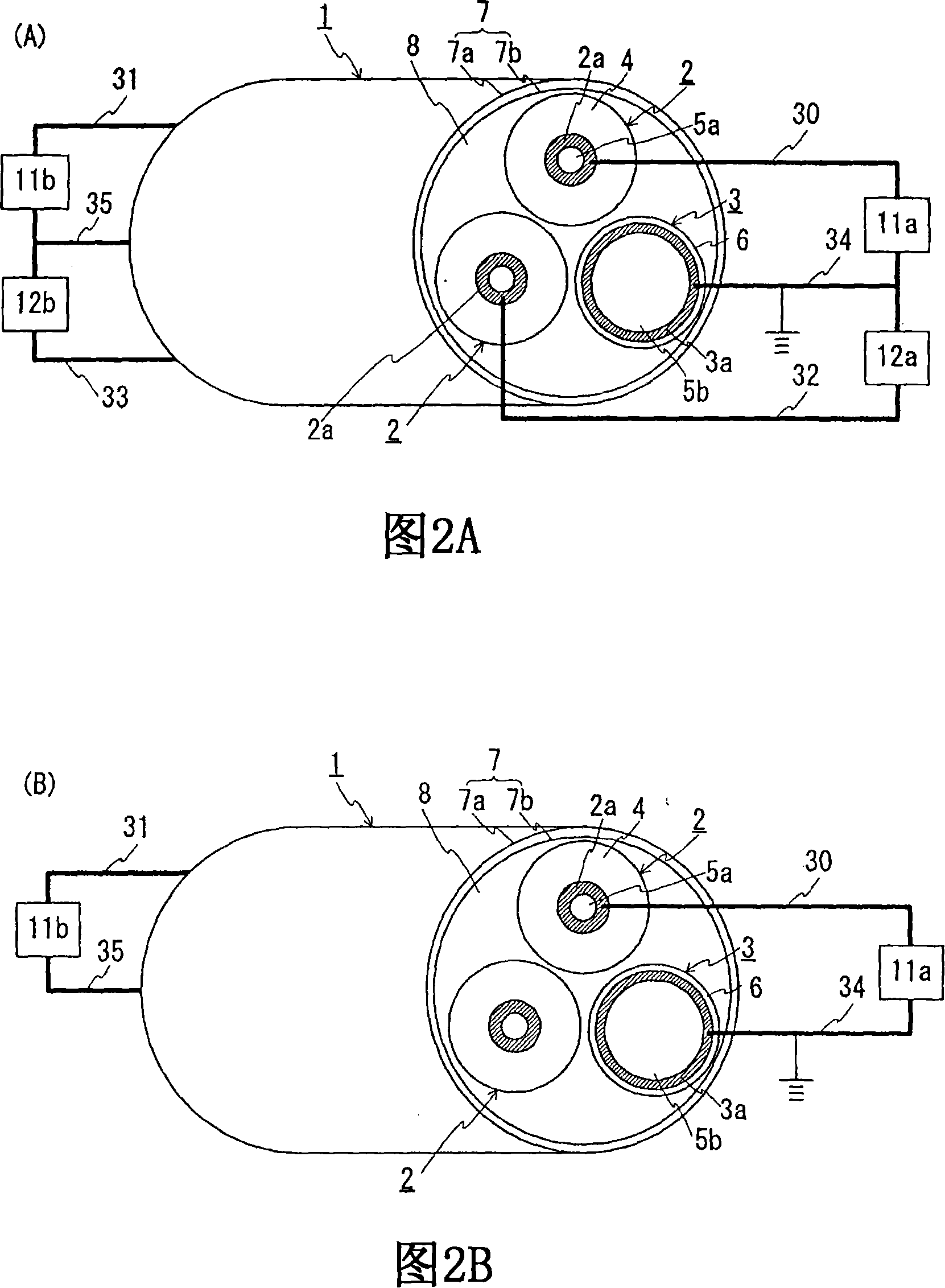

[0106]Next, the case where bipolar transmission is performed is explained. FIG. 2(A) is a schematic structural view showing a state in which a DC transmission line for bipolar transmission is constructed by using the superconducting cable of the present invention. FIG. 2(B) is a schematic configuration diagram showing a state in which a DC transmission line for unipolar transmission is constituted by using one of two first cores and a second core. The superconducting cable 1 used in Example 1 can also be used for bipolar transmission. For bipolar transmission, it is recommended to construct the transmission line as shown in Fig. 2(A). More specifically, one end of the first superconducting layer 2a provided in one of the two first cores 2 (in FIG. 2(A), the top first core 2) is connected to the DC-AC conversion 11a, the converter is connected to an AC system (not shown). The other end of the same first superconducting layer 2a is connected via a lead wire 31 to a DC-AC conv...

example 3

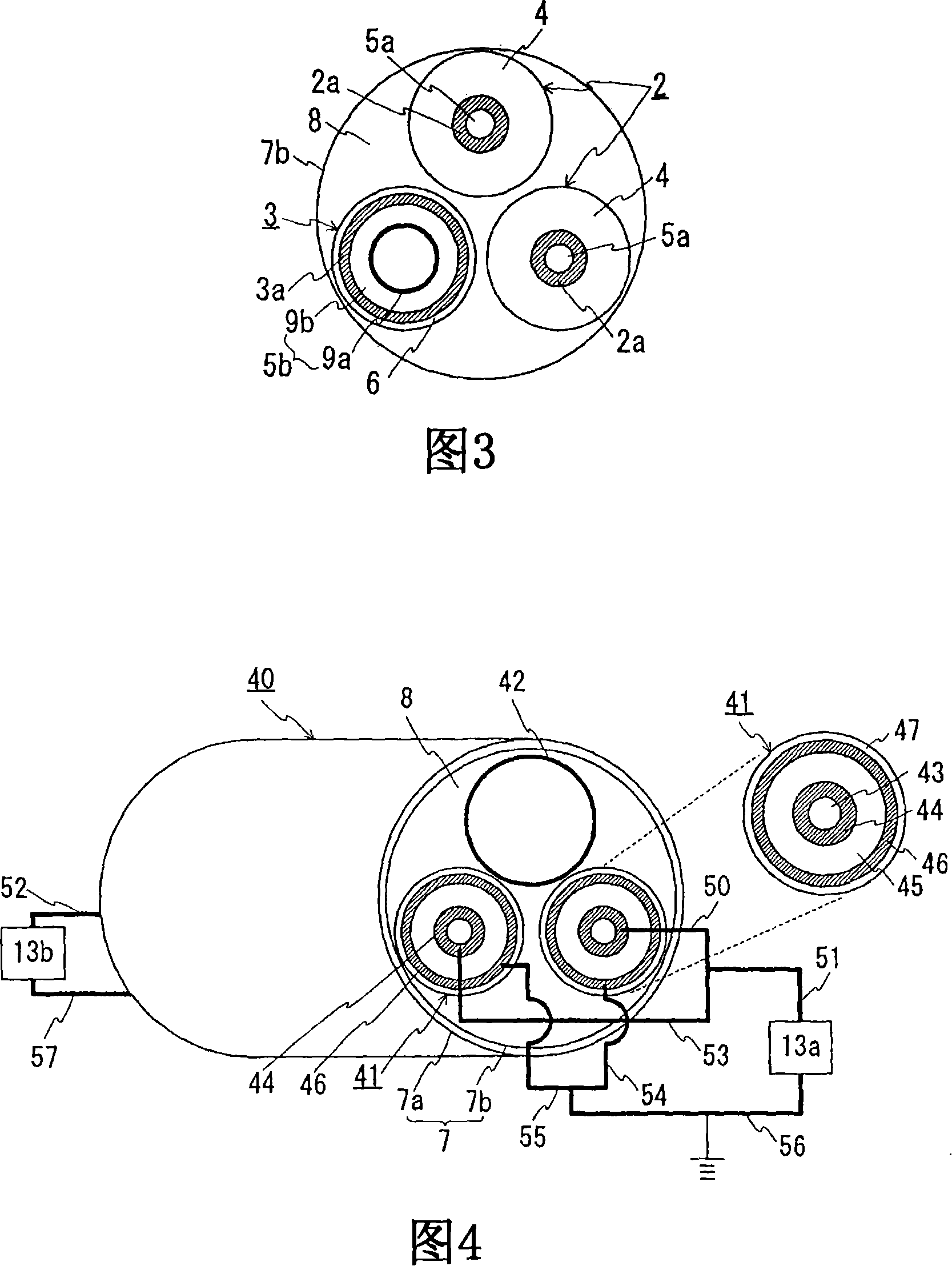

[0117] In the above-mentioned Embodiments 1 and 2, an explanation was given to the structure of the core member in which the stranded copper wire was used as the second core. However, a coolant circulation pipe may be used as the core member. 3 is a schematic cross-sectional view showing a superconducting cable of the present invention having a coolant circulation pipe inside a second superconducting layer of a second core. The second core 3 shown in this example has the same basic structure as that shown in Examples 1 and 2. The only difference is that a coolant circulation pipe 9a is provided as an inner core member of the core member 5b. An explanation is given below by focusing on this point.

[0118] In this example, the coolant circulation pipe 9a is formed using a corrugated stainless steel pipe. The insulating layer 9b is formed on the outer periphery of the coolant circulation pipe 9a by spirally winding a semi-synthetic insulating layer. In this example, in parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com