Differential lifting high-order tippler

A dumper and high-level technology, applied in the field of material unloading equipment, can solve problems such as high energy consumption, unreasonable design, and affecting the normal operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

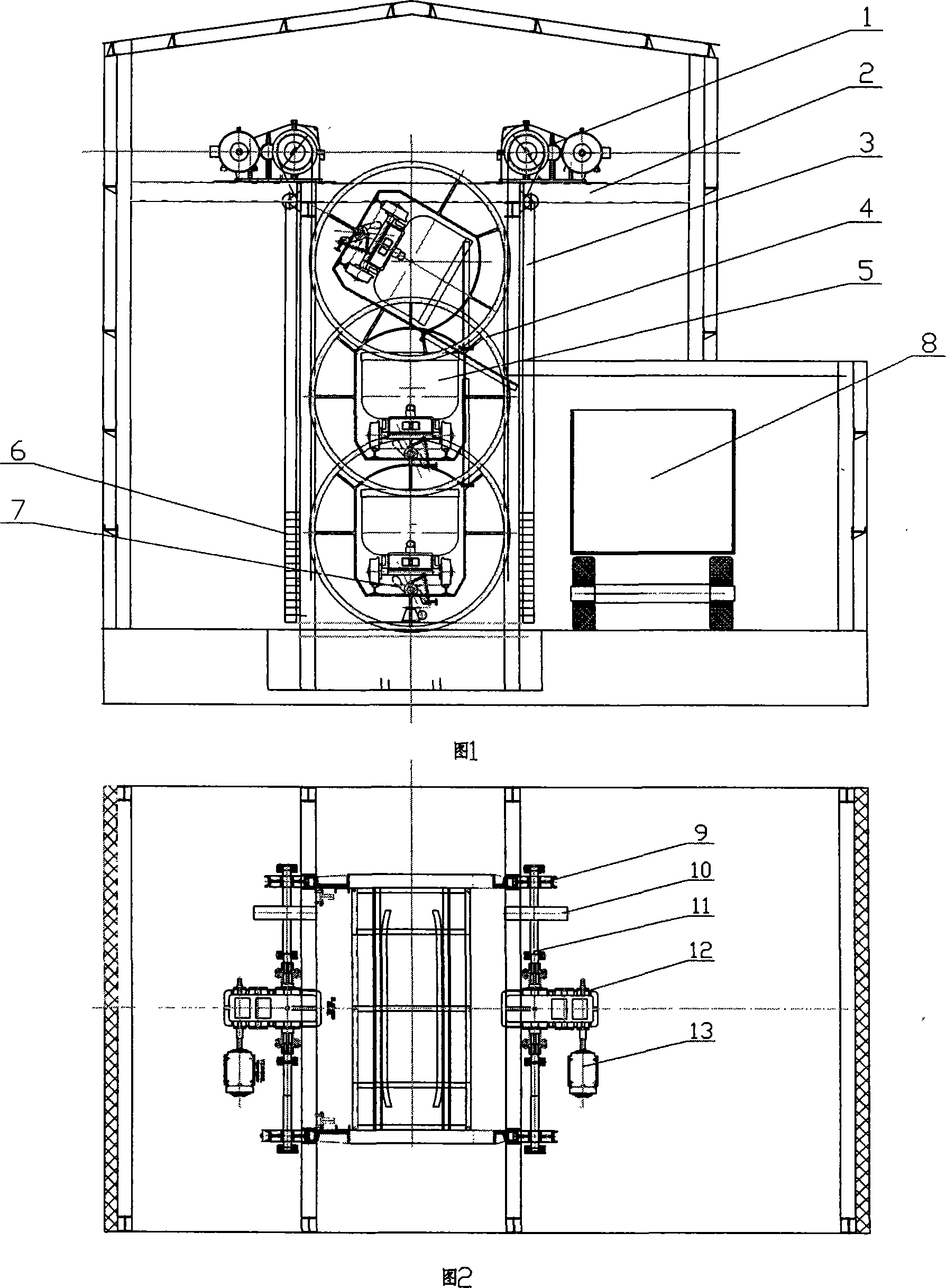

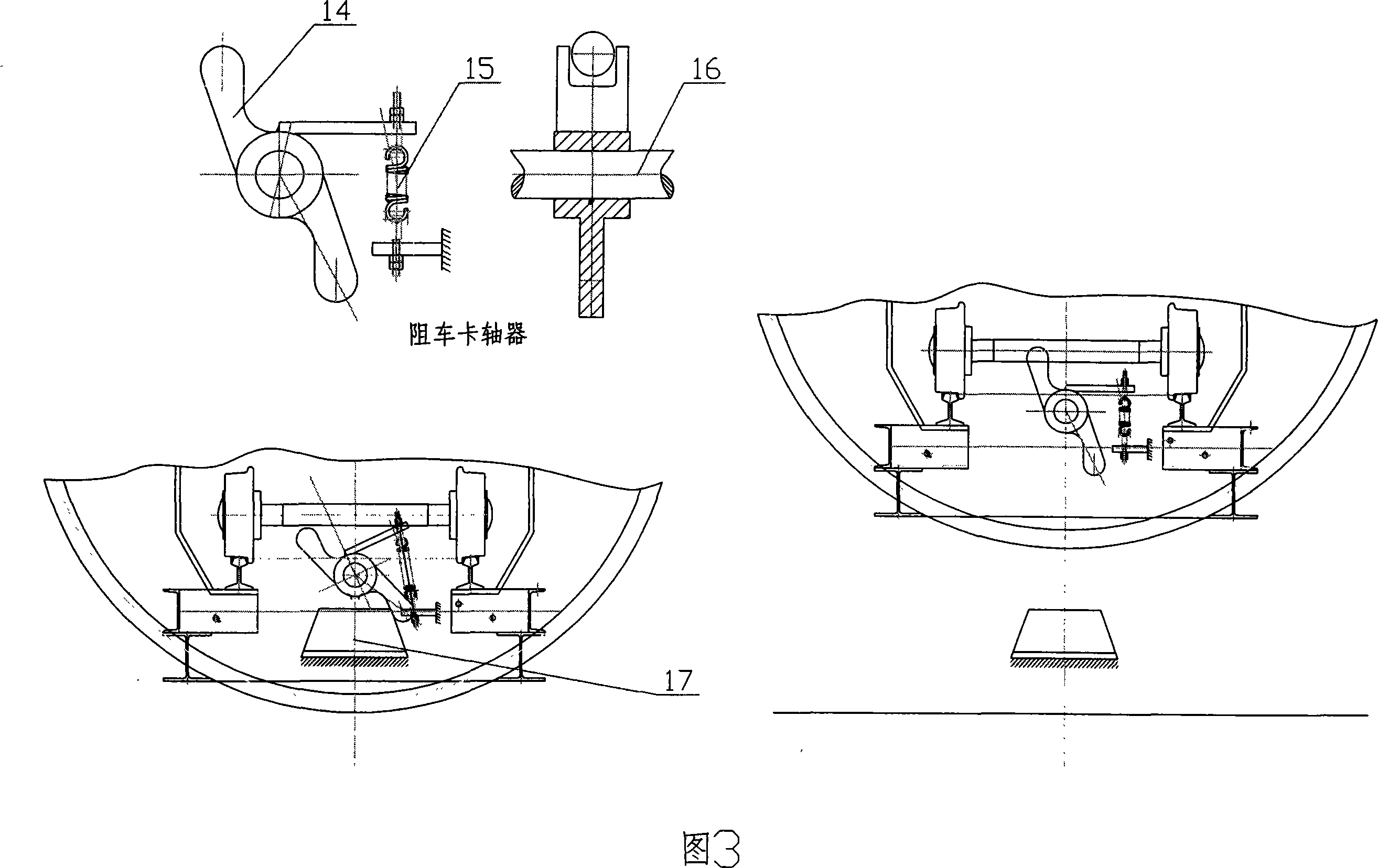

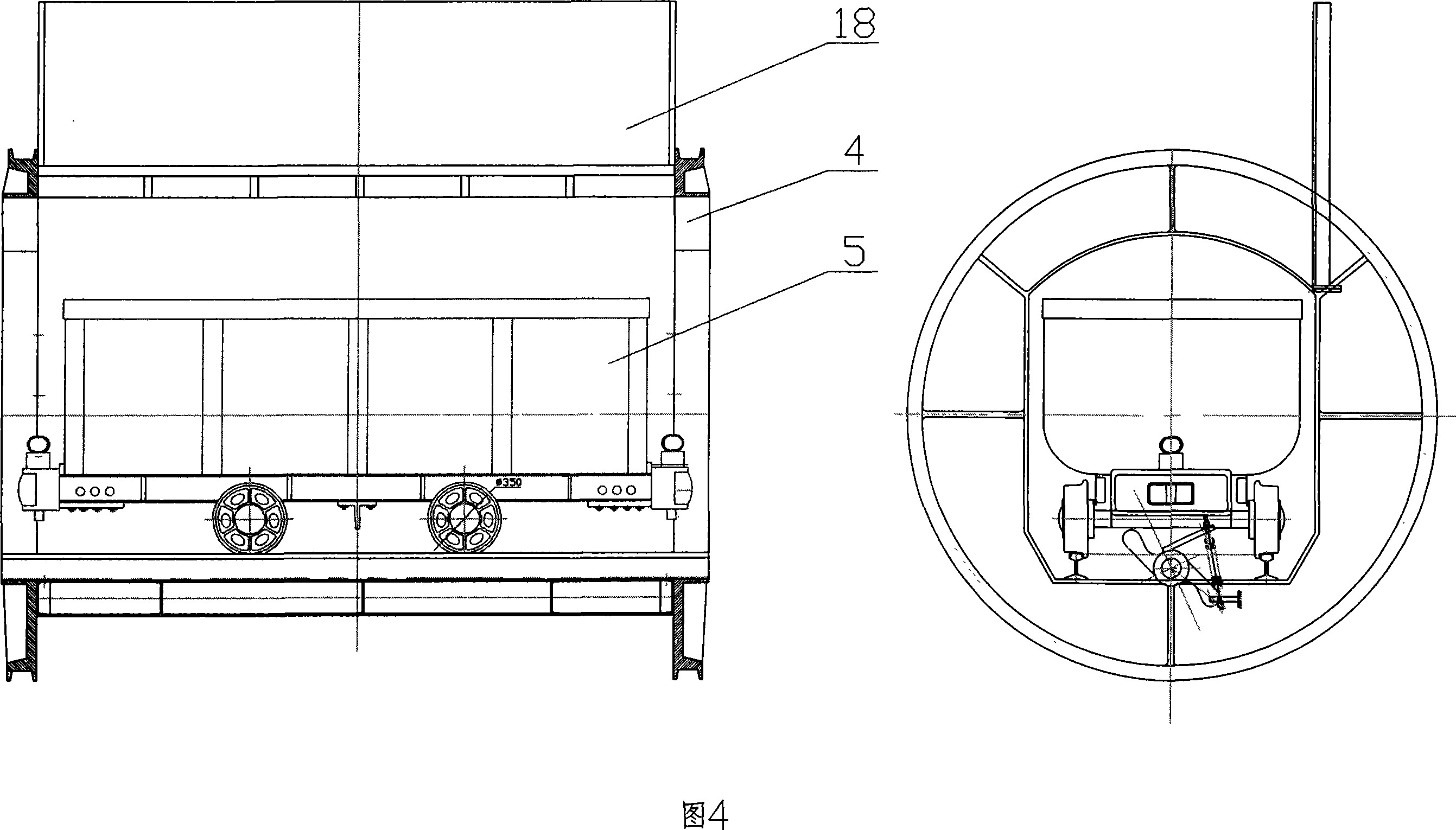

[0012] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0013] It can be seen from the accompanying drawings that the differential lifting high-position dumper of this program consists of a steel structure lifting bracket and a workshop assembly (2), an electric motor (13), a reduction box (12), a drive shaft (11), and a friction wheel (9 )composition. The lifting drive device (1) composed of the electric motor (13), reduction box (12), drive shaft (11), and friction wheel (9) is symmetrically arranged above the steel structure lifting bracket and the workshop assembly (2). One end of the hoisting wire rope (3) is connected to the round rolling cage (4), and the other end is wound three times on the friction wheel (9), so that the end is drooped and anchored with the balance weight (6). Winding three circles on the wheel (9) can make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com