Traveling crane positioning system and positioning method

A positioning system, crane technology, applied in the direction of load hanging components, transportation and packaging, to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

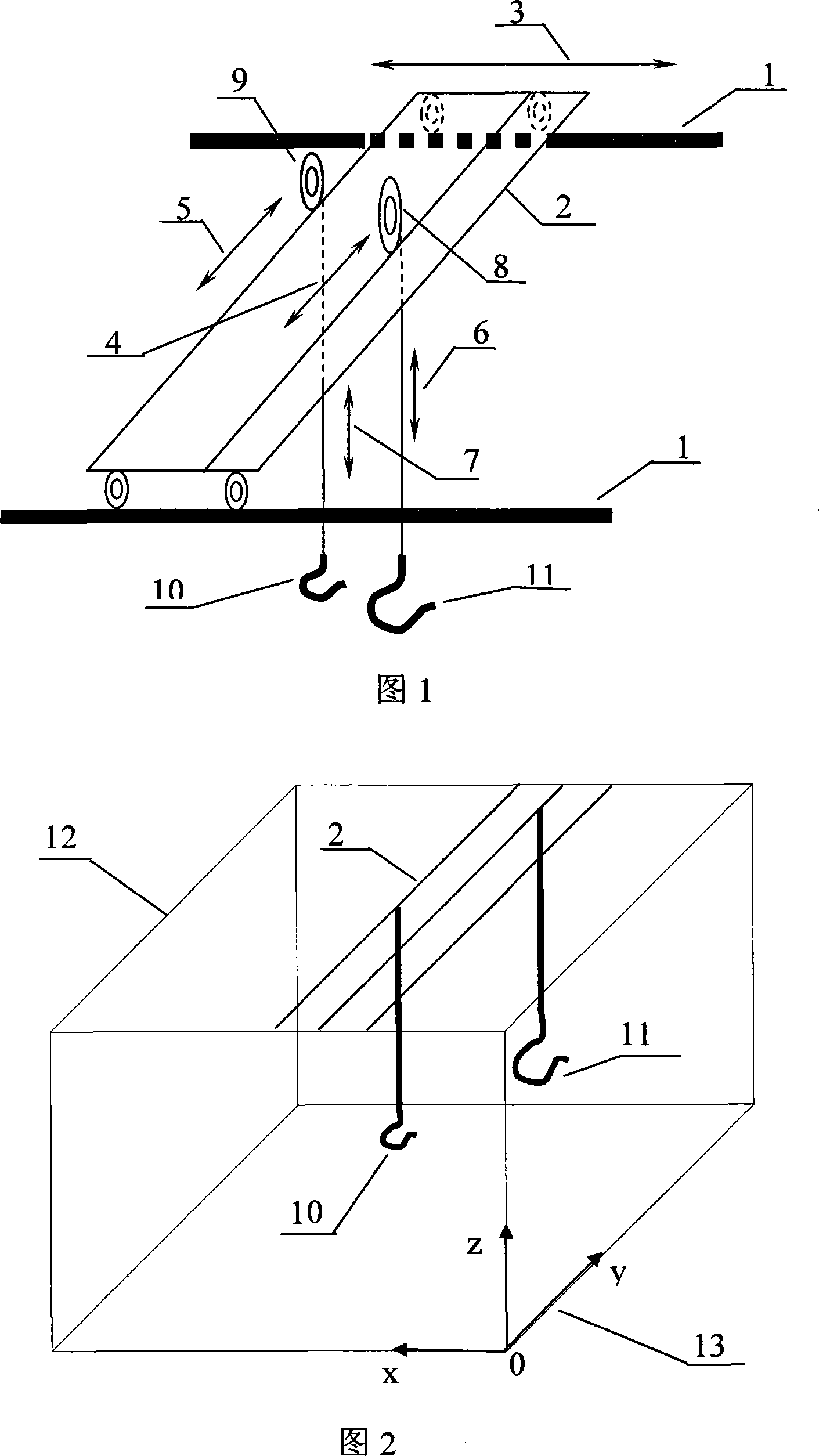

[0040] In Fig. 1, the layout diagram of the position positioning of the crane is given. It can be seen from Figure 1 that the crane is composed of a cart, main and auxiliary trolleys, and main and auxiliary hooks. If the crane wants to lift a heavy object, it should first drive the cart to run directly above the position of the heavy object. Adjust the position of the main and auxiliary trolleys so that the hook is directly above the heavy object, and finally adjust the height of the main hook to lift the heavy object. From this process, the coordinates of the positioning of the crane can be obtained, that is, the running direction of the large crane is x, the running direction of the main trolley and auxiliary trolley of the crane is y, and the running direction of the main and auxiliary hooks is set to z. Through this coordinate, the location of the transferred goods can be precisely located.

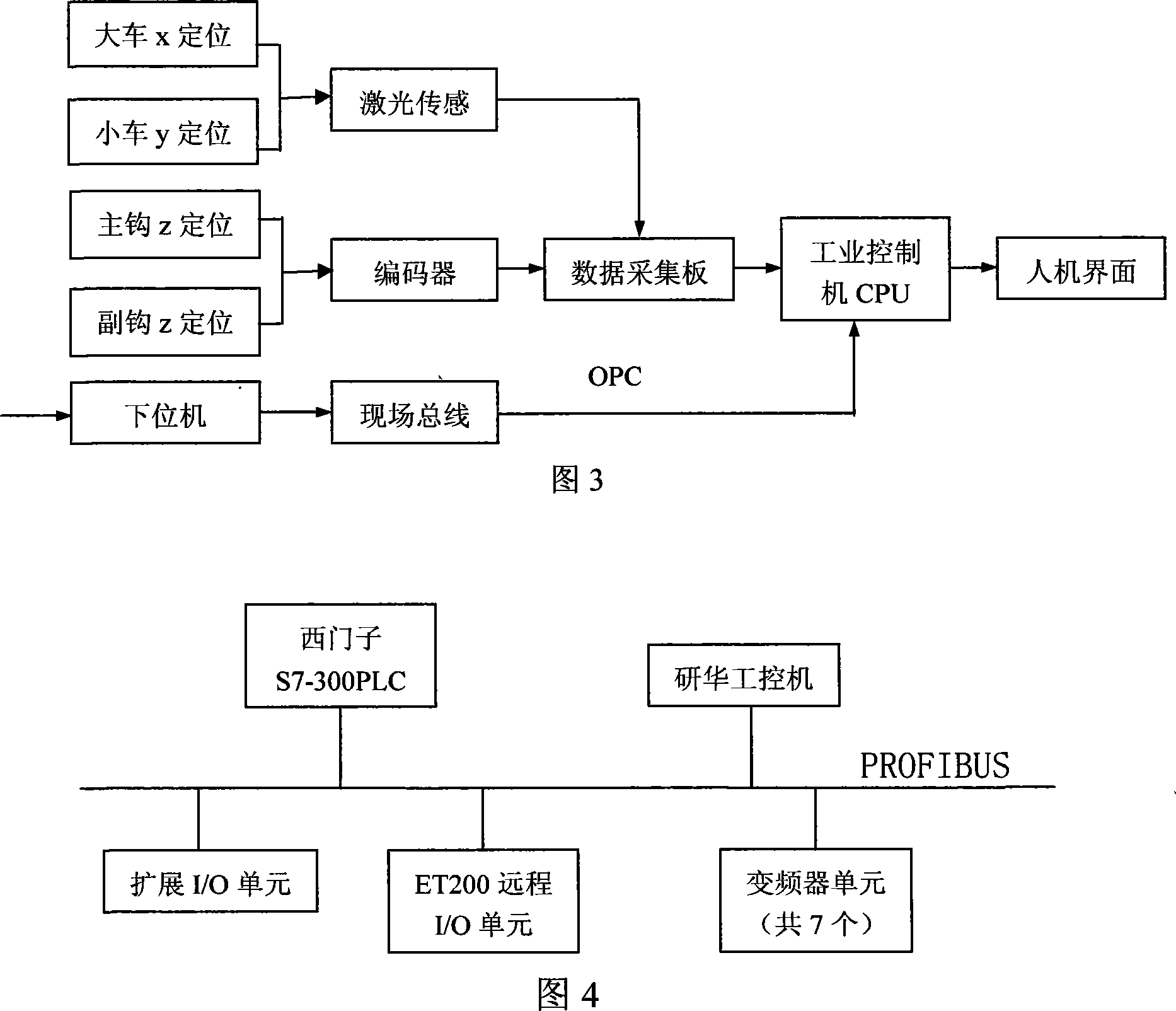

[0041] Figure 2 shows the coordinate system setting position map of the crane po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com