Fixed point injection positioning sprinkling type lubricating system for offset press

A technology for lubrication systems and offset printing machines, applied in the field of lubrication systems, can solve problems such as uneven lubrication of offset printing machines and affect printing quality, and achieve the effects of ensuring normal operation, stable printing quality, and prolonging the mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

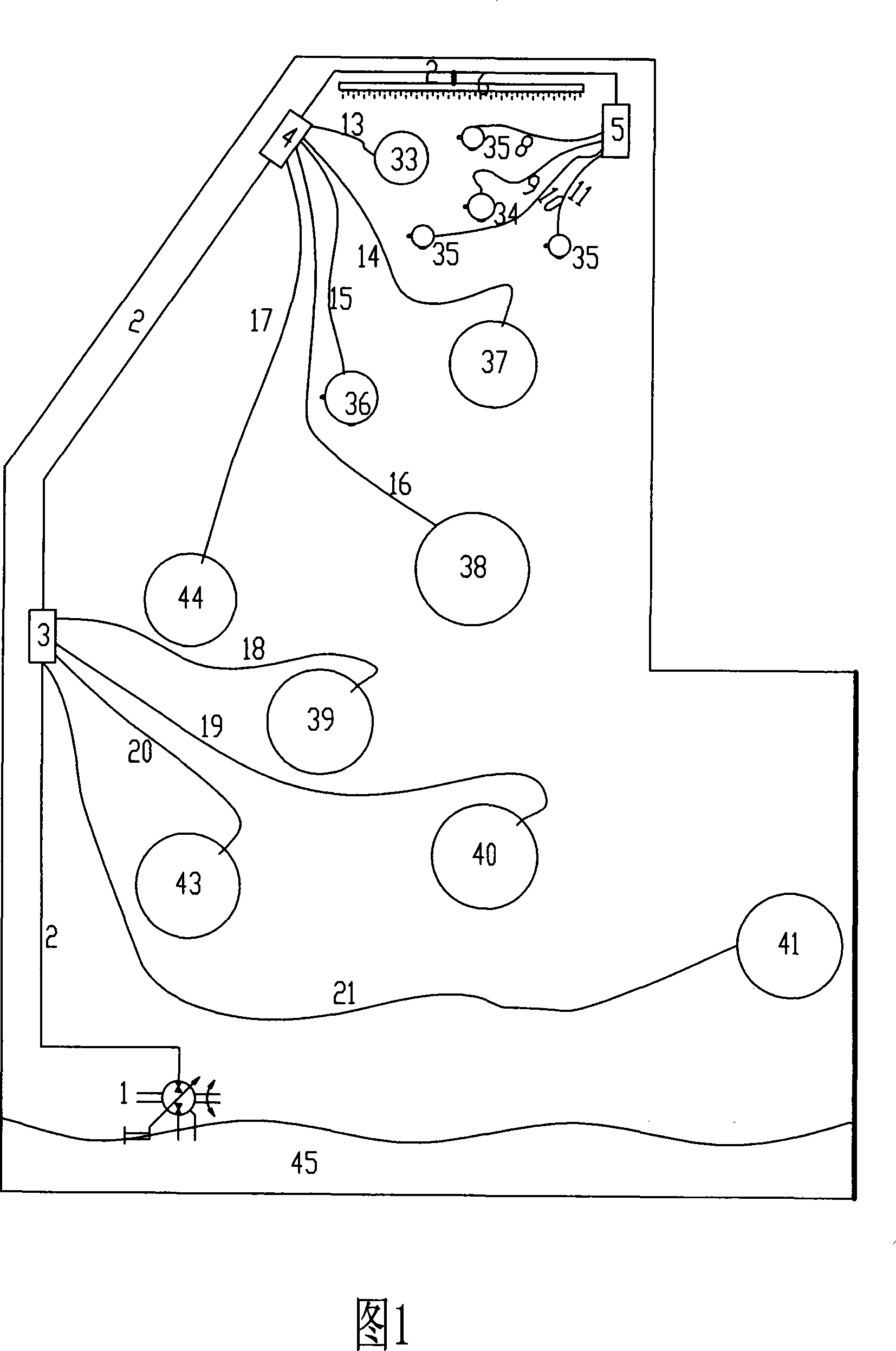

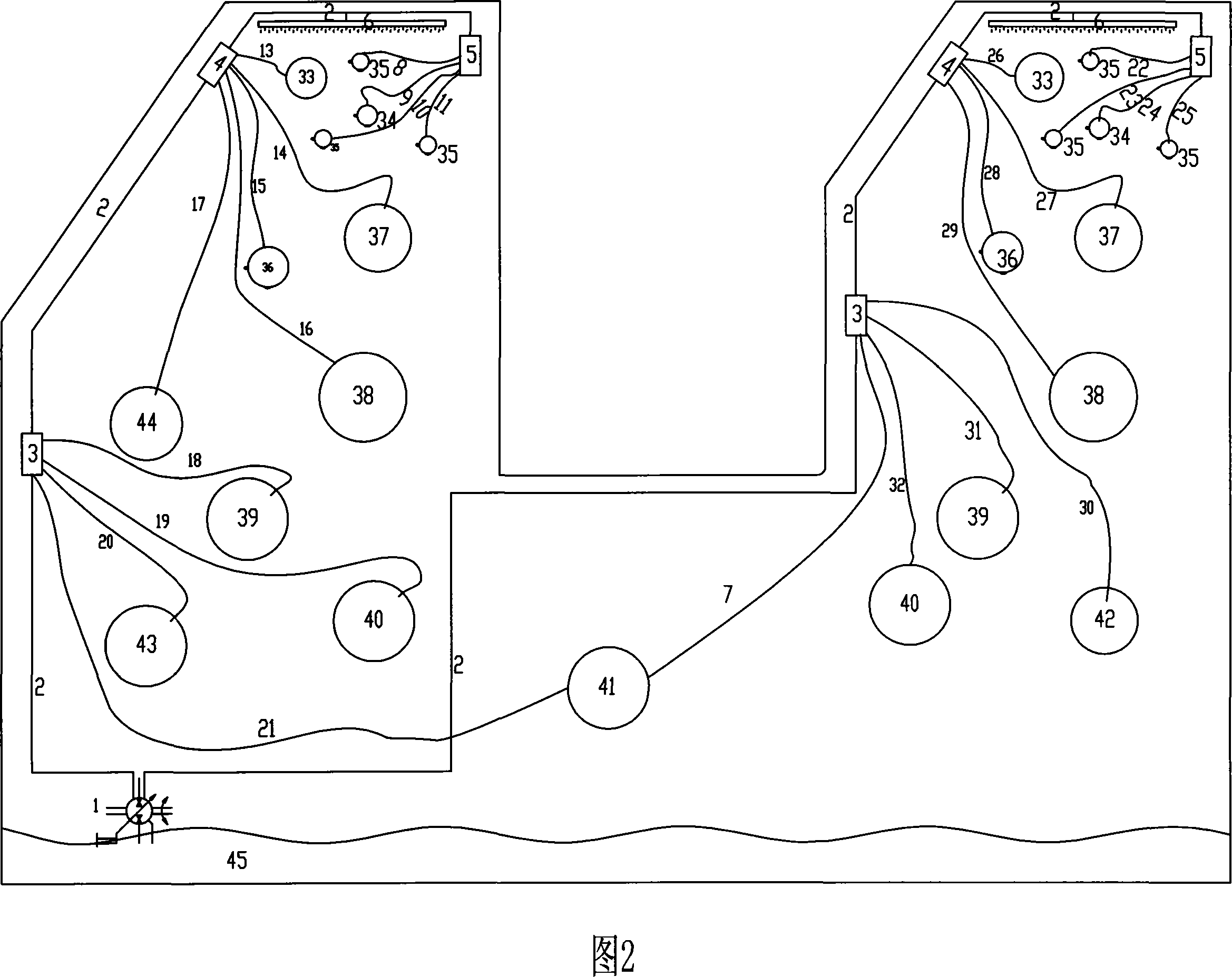

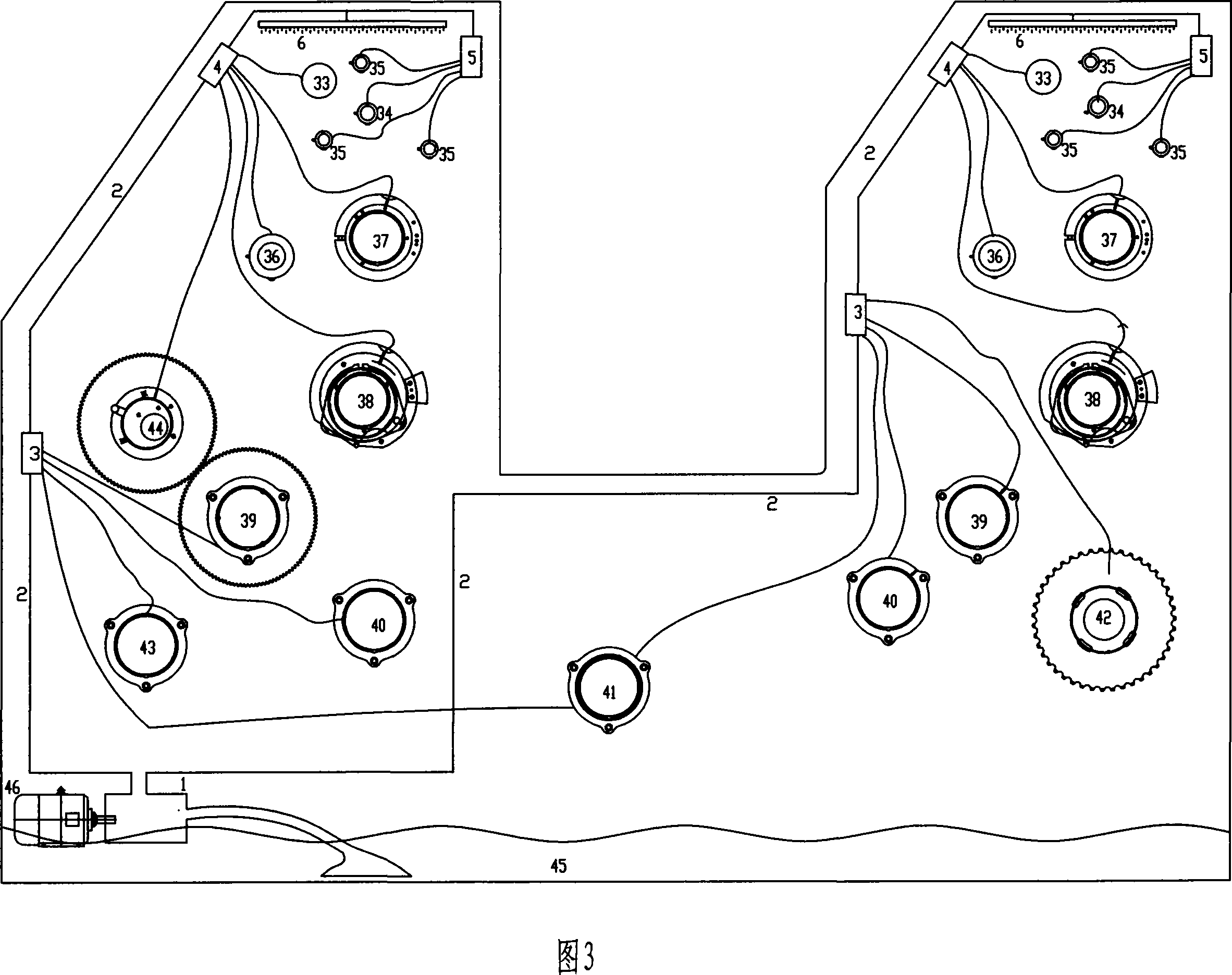

[0011] The structure of the lubricating system combined with graded injection and spraying is shown in Figure 1, which represents the pipeline structure of the forced oil inlet of each shaft sleeve in the lubricating system of the split monochrome offset printing machine. It consists of three graded splitters connected in series in the main oil supply pipe respectively. After the lubricating oil pumped in from the oil pump passes through the splitters at all levels, the pressure and flow decrease step by step. Oil lubricating the impression cylinder, rubber cylinder and printing plate cylinder with larger diameter from the pressure and flow device, and lubricating the roller shaft with smaller diameter from the oil with lower pressure and flow rate than the primary diverter from the secondary diverter , such as inking, water rollers, etc., the lubricating oil is drawn from the three-stage shunt to supply small-diameter auxiliary rollers, such as ink rollers or bridge rollers, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com