Coke dry quenching all-system dynamic air tight test method

A test method and a system-wide technology, applied in liquid tightness measurement using liquid/vacuum degree, coke oven, coke cooling, etc., can solve the problem of consuming a lot of manpower, material resources, financial resources, and no clear standard for pressure drop judgment , the effect is not obvious and other problems, to achieve the effect of reducing construction costs, improving construction efficiency and benefits, and direct test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

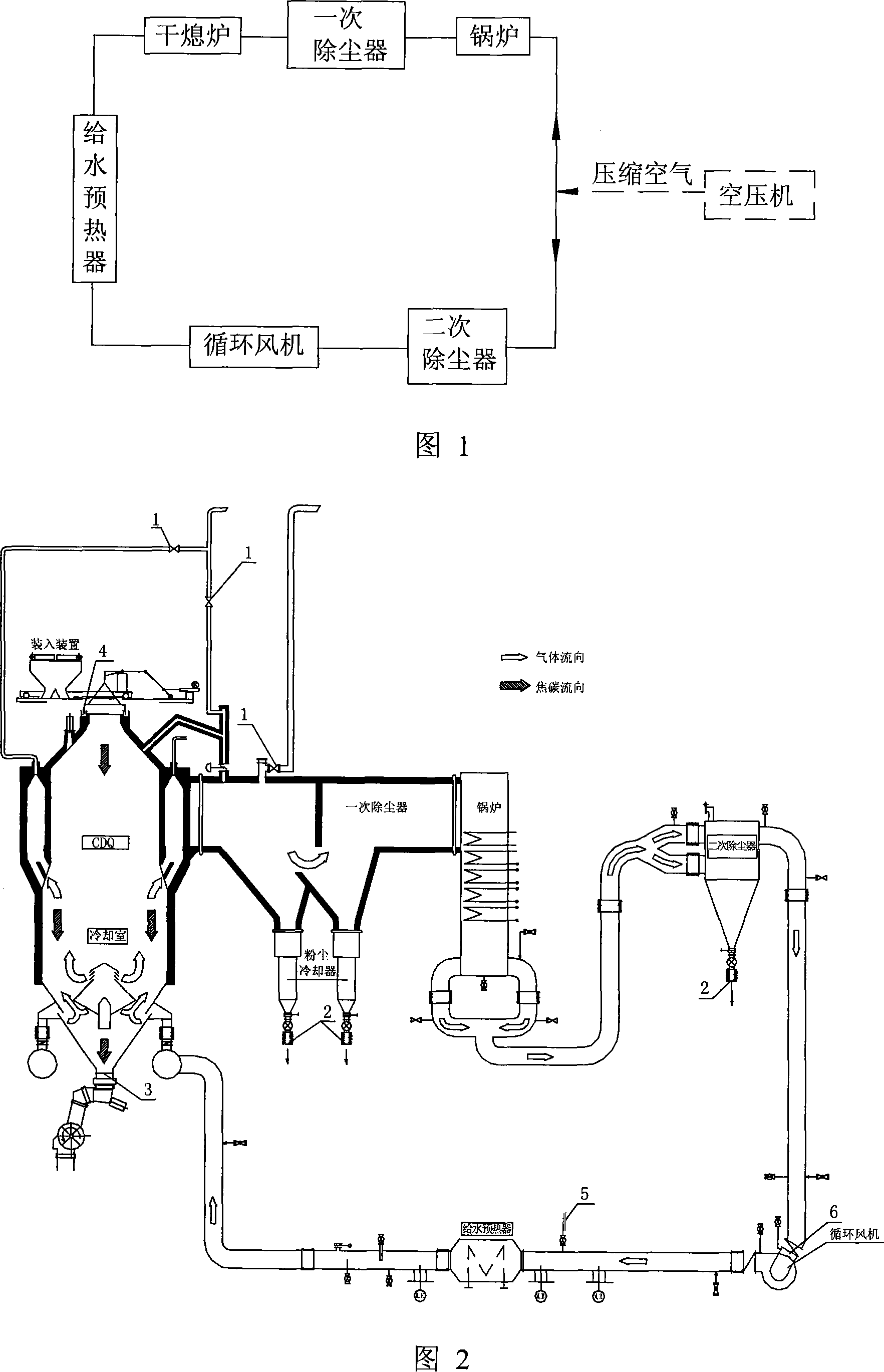

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

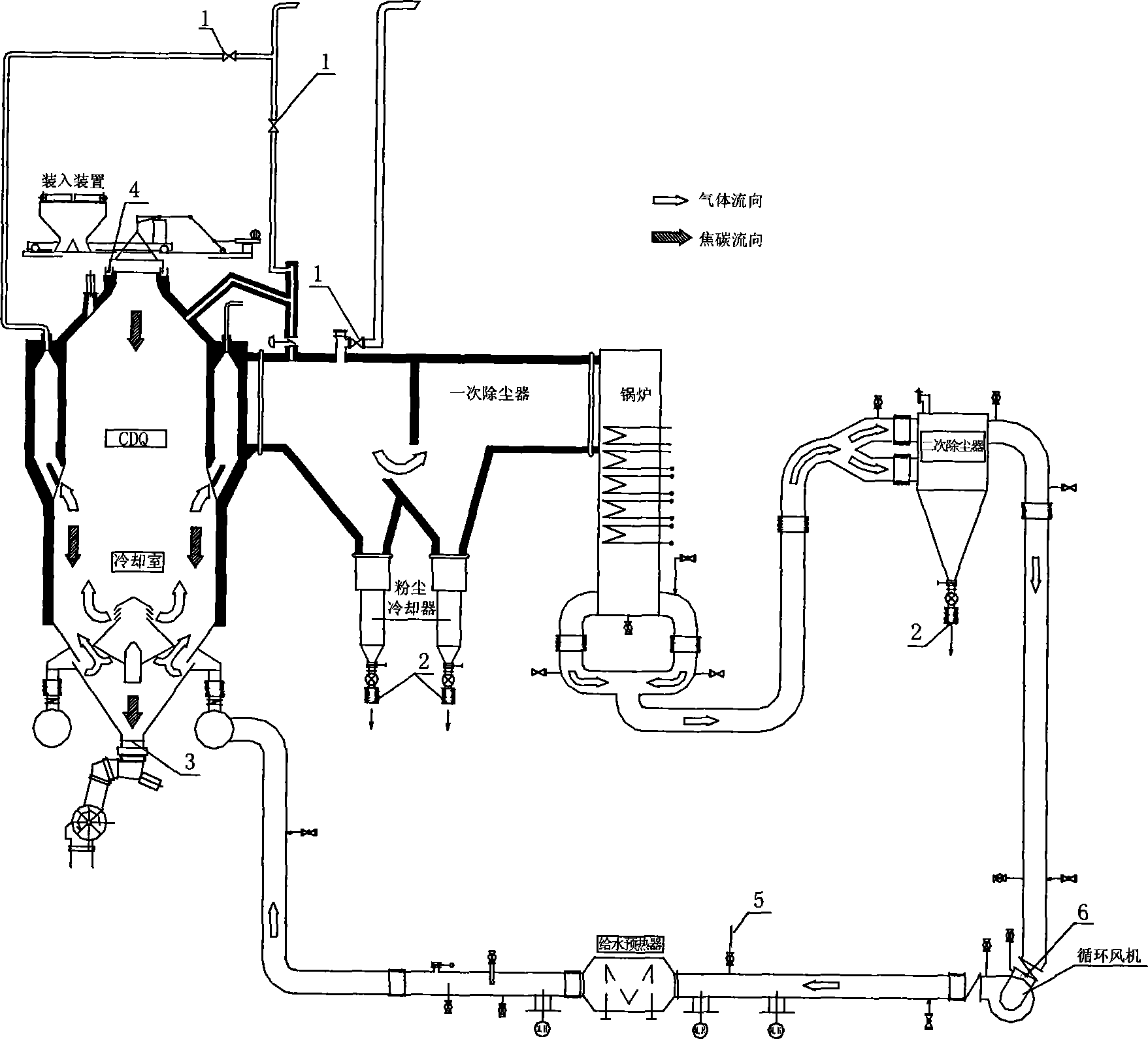

[0028] Referring to Fig. 2, a method for dynamic air tightness test of CDQ whole system is carried out according to the following steps:

[0029] 1) Close the valves of the whole CDQ system, including closing the emergency gas release cut-off valve 1, the lower insert valve of the primary and secondary dust collectors 2, the plate valve of the discharge device 3, the furnace top bypass valve, the boiler top release valve, the air Inlet pipe cut-off valve, etc. The upper short pipe flanges of each section of the coke quenching oven, that is, the operation hole of the air volume distribution adjustment brick, do not tighten the bolts during production, only need to cover the blocking plate, and generally tighten the bolts to maintain the system air pressure.

[0030] 2) Plug the natural leakage points of the whole CDQ system, fill the water seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com