Black film liquid crystal display screen and its box manufacture process

A technology of liquid crystal display and box technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as uneven box thickness, poor overall consistency, and low product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

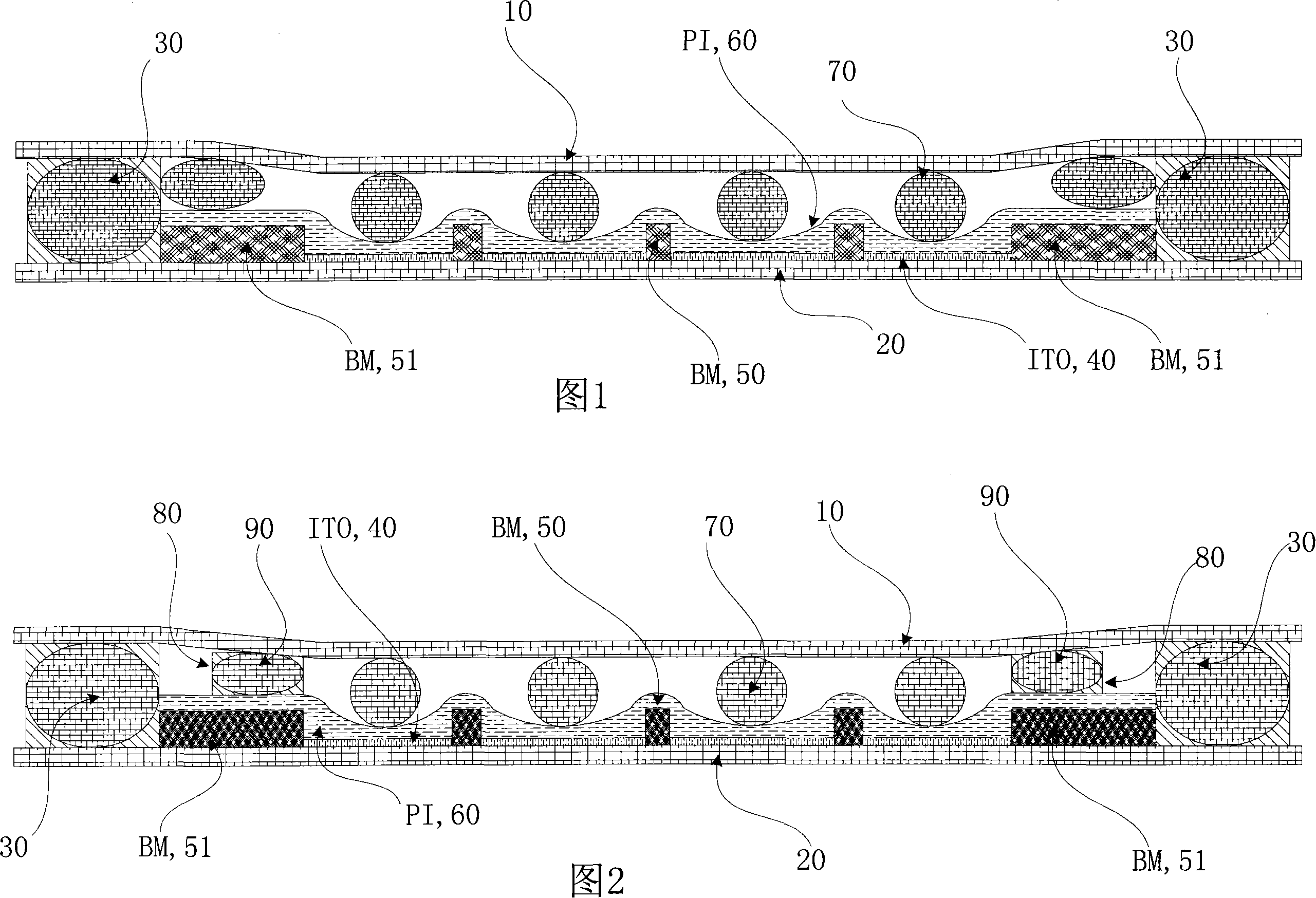

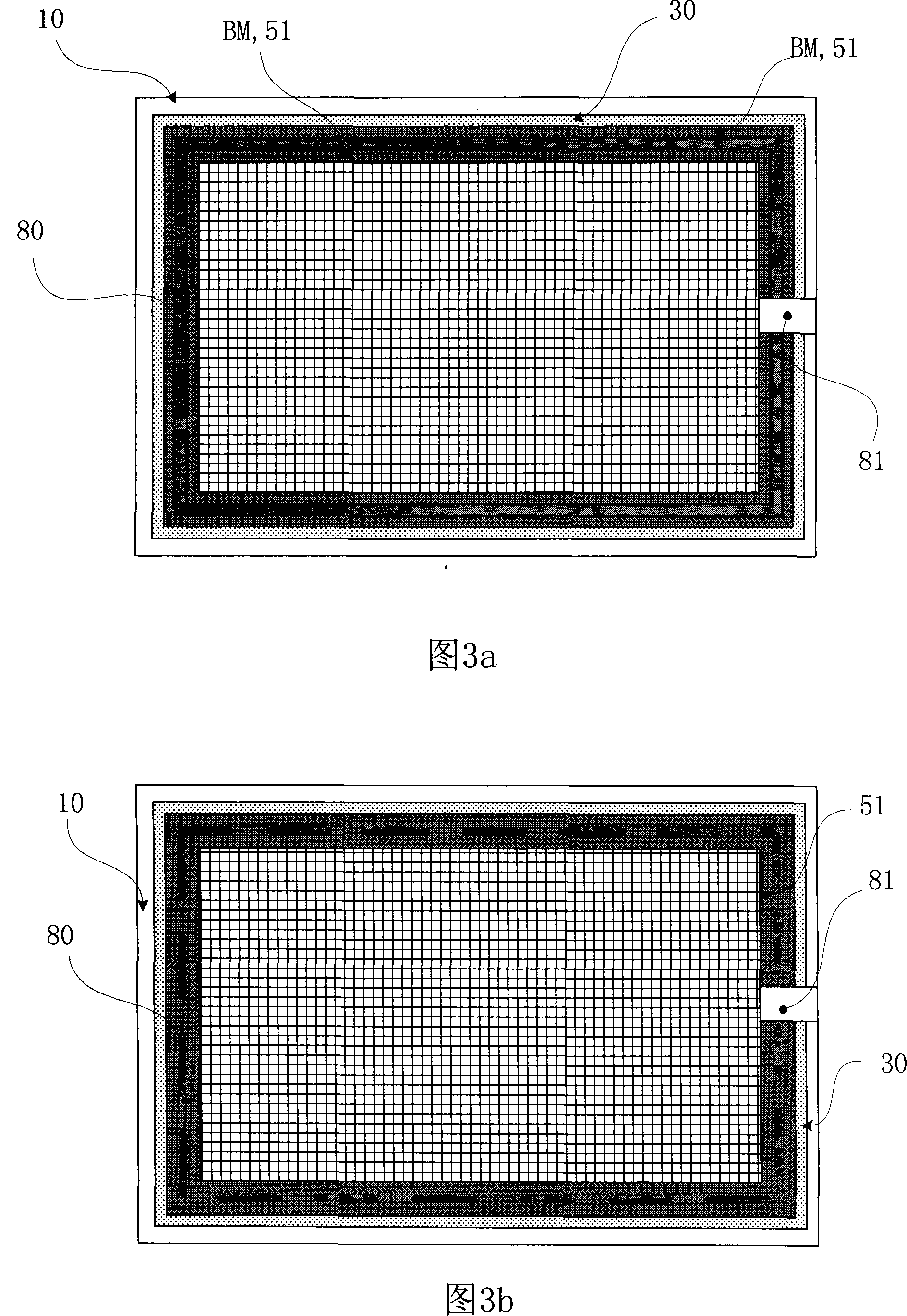

[0020] Various embodiments of the present invention are described with reference to the above-mentioned drawings.

[0021] The box-making process of the black film liquid crystal display includes the following process steps:

[0022] A. Apply a black compensation film to the etched and developed glass plate A;

[0023] B. Apply PI glue on glass A and B;

[0024] C. After curing and rubbing, print the frame material;

[0025] D. Spray liner separator;

[0026] E. Bonding hot pressing;

[0027] The step C also includes the following steps:

[0028] While printing the frame material, a colloidal annular support frame is also printed on the black compensation film frame film, and the support frame contains a liner spacer; the diameter of the liner spacer in the support frame is smaller than that in step D The diameter of the sprayed liner spacer.

[0029] In the process of spraying the spacer on the traditional black film liquid crystal display, the spacer often stays on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com