Blade for wind-power generators

A generator and blade technology, which is applied to wind turbines, wind energy power generation, wind turbines in the same direction as the wind, etc., can solve problems such as increased cost and weakening of longitudinal internal reinforcement structures, and achieves the effect of eliminating risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

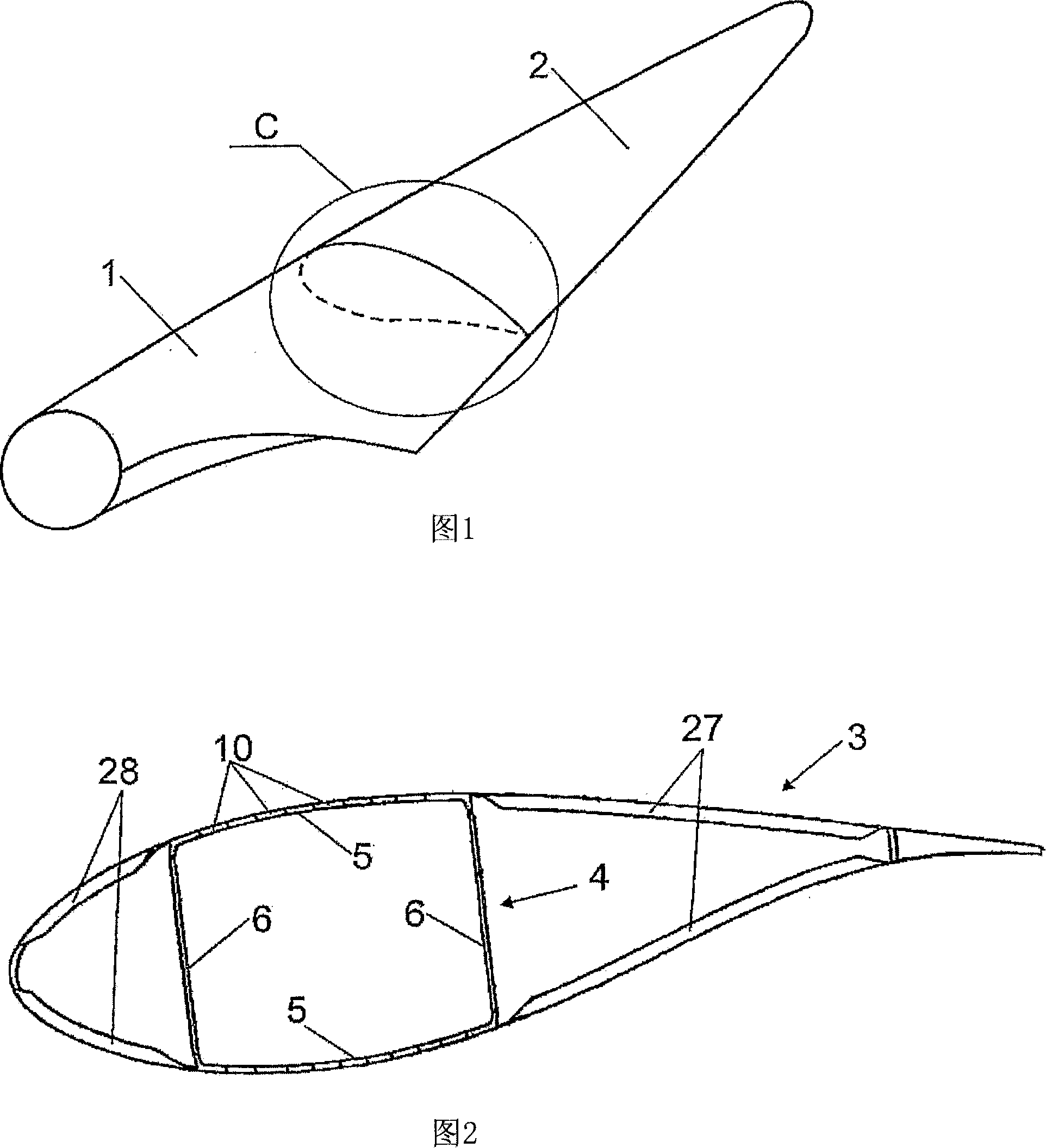

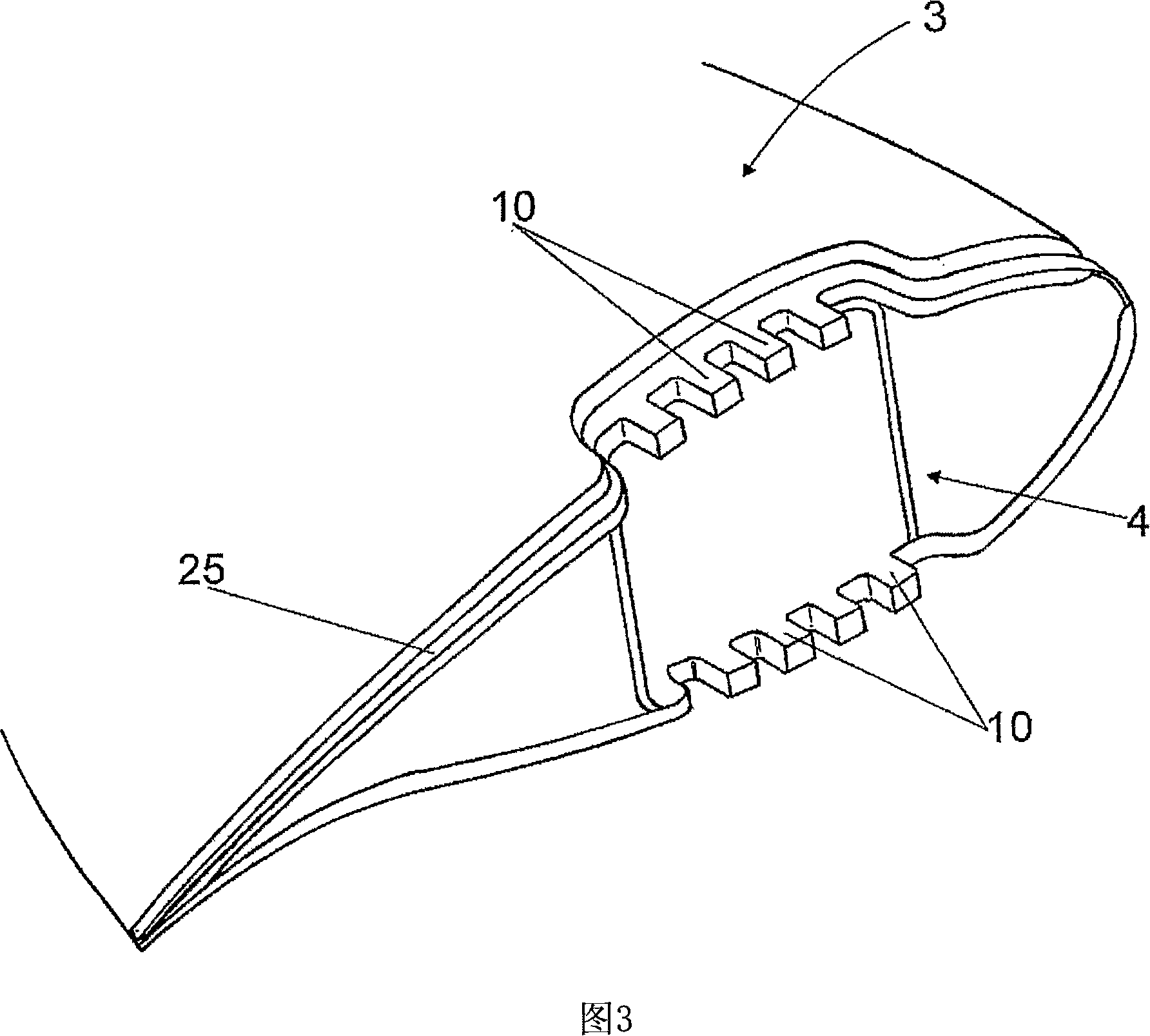

[0034] FIG. 1 shows a blade of a wind power generator of conventional configuration subdivided transversely into two parts, designated with reference numerals 1 and 2 . These parts have matching opposing locations, as shown in plan and perspective views in FIGS. 2 and 3 .

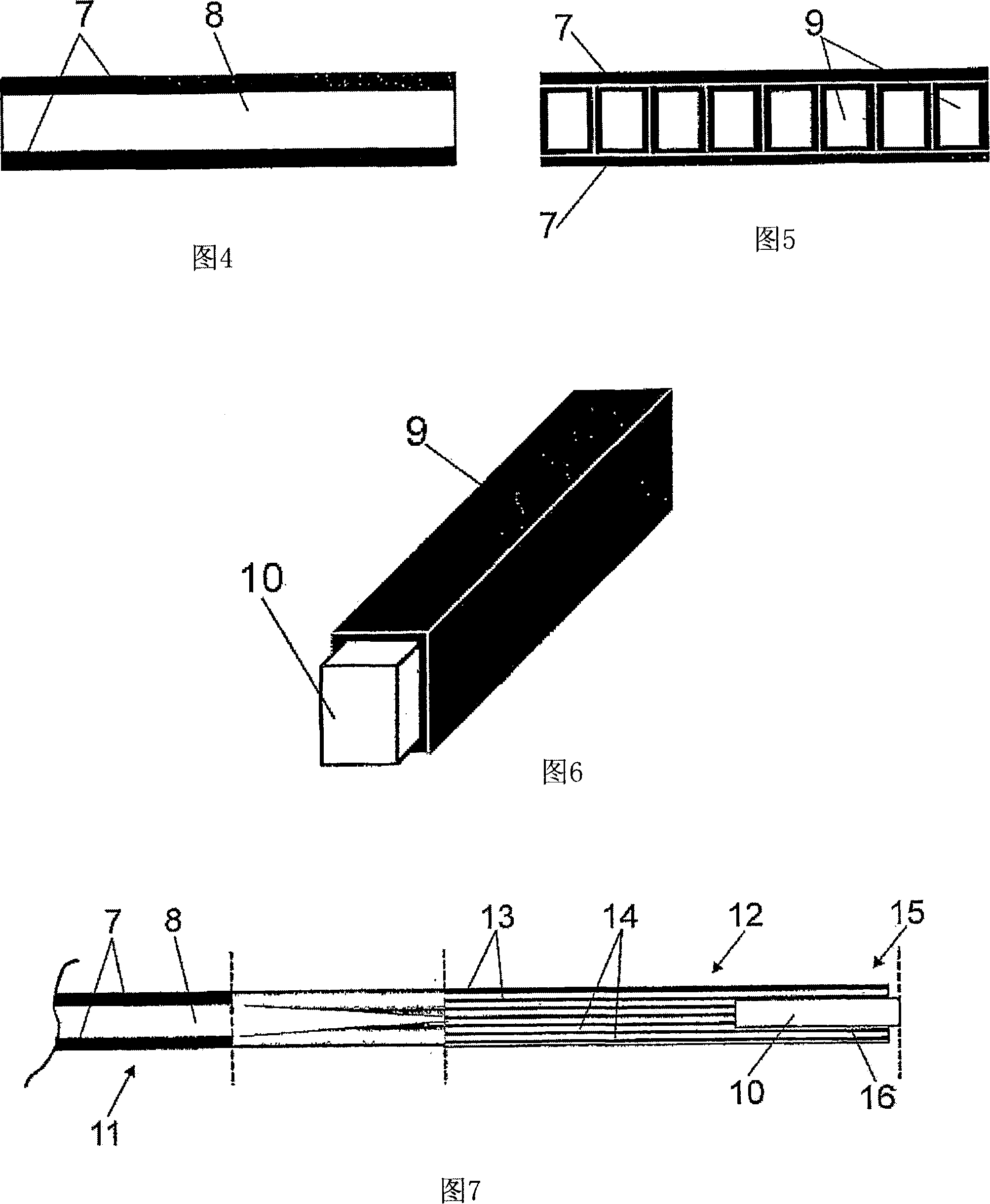

[0035] Each of sections 1 and 2 comprises an outer aerodynamic wall or shell, designated 3, and a longitudinal internal stiffening structure, designated 4, which in the example shown in the drawings The inner reinforcing structure is conceived as a box beam extending along said part, wherein said box beam has a wall 5 adjoining and forming part of the shell 3 and an intermediate wall 6 .

[0036] Parts 1 and 2 have connecting members at their opposite locations, said means being located at adjacent end locations of the longitudinal inner reinforcing structure 4 . Preferably, the aforementioned connection members are positioned to coincide with the wall portion 5 of the longitudinal internal reinforcement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com