System for ultrahigh speed railway train running in vacuum tunnel (pipeline)

A vacuum tunnel and ultra-high-speed technology, applied in tunnel systems, roads, railway transportation, etc.

Inactive Publication Date: 2008-04-02

杨福顺

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

So much so that the current general view is that it is unimaginable and difficult to realize a railway train transportation system used by a large number of people in a vacuum environment like a space environment on a large scale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0044] Embodiment: Establish the east coast from China to West Europe (Paris, France, London, England) via Eastern Europe and from Singapore to North America (Canada, United States) via the Bering Strait, and then from the United States to Central America. South American countries have formed a globalized high-volume ultra-high-speed railway train system that is faster than airplanes, safe, and low-cost, and travels in vacuum tunnels.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

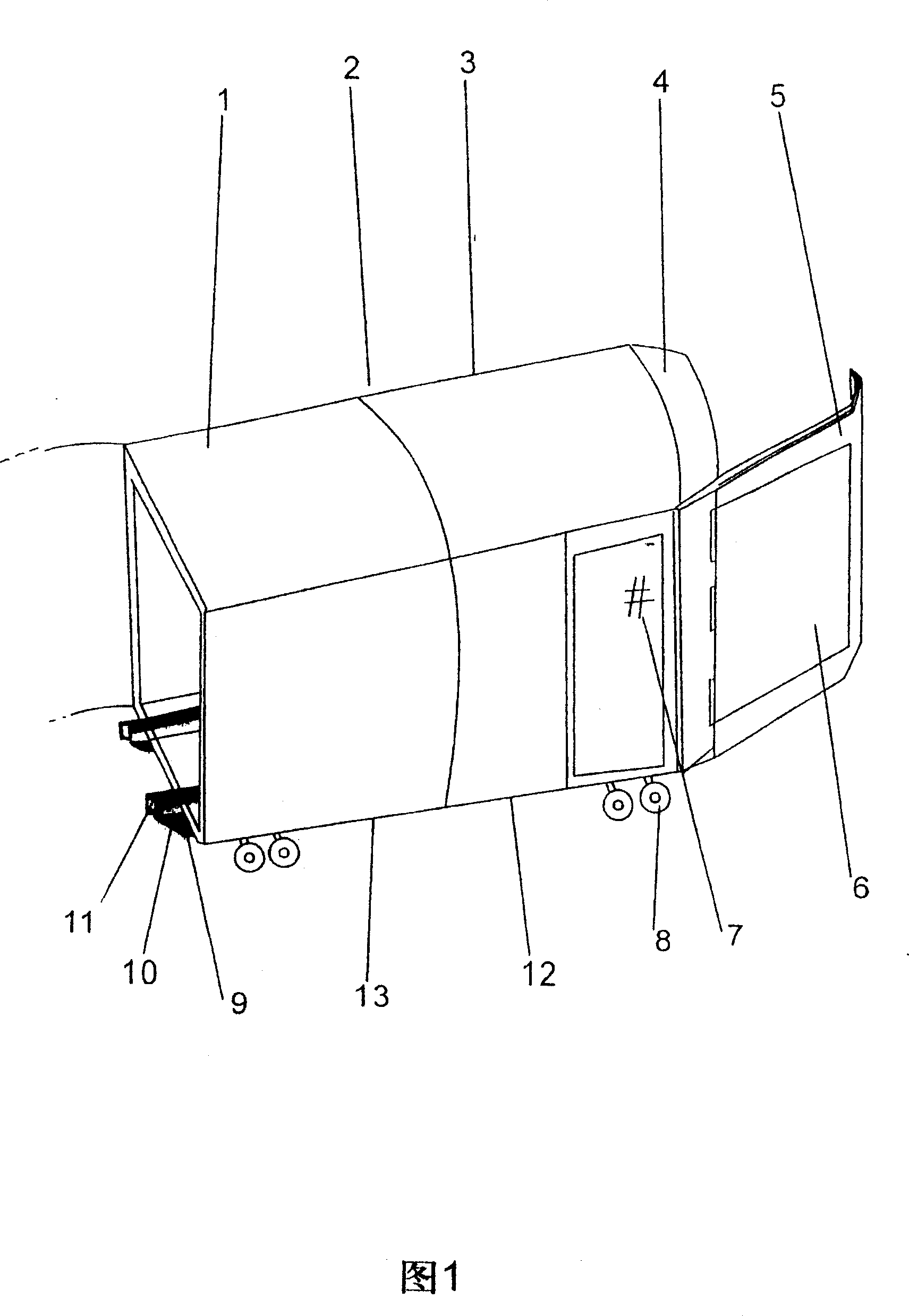

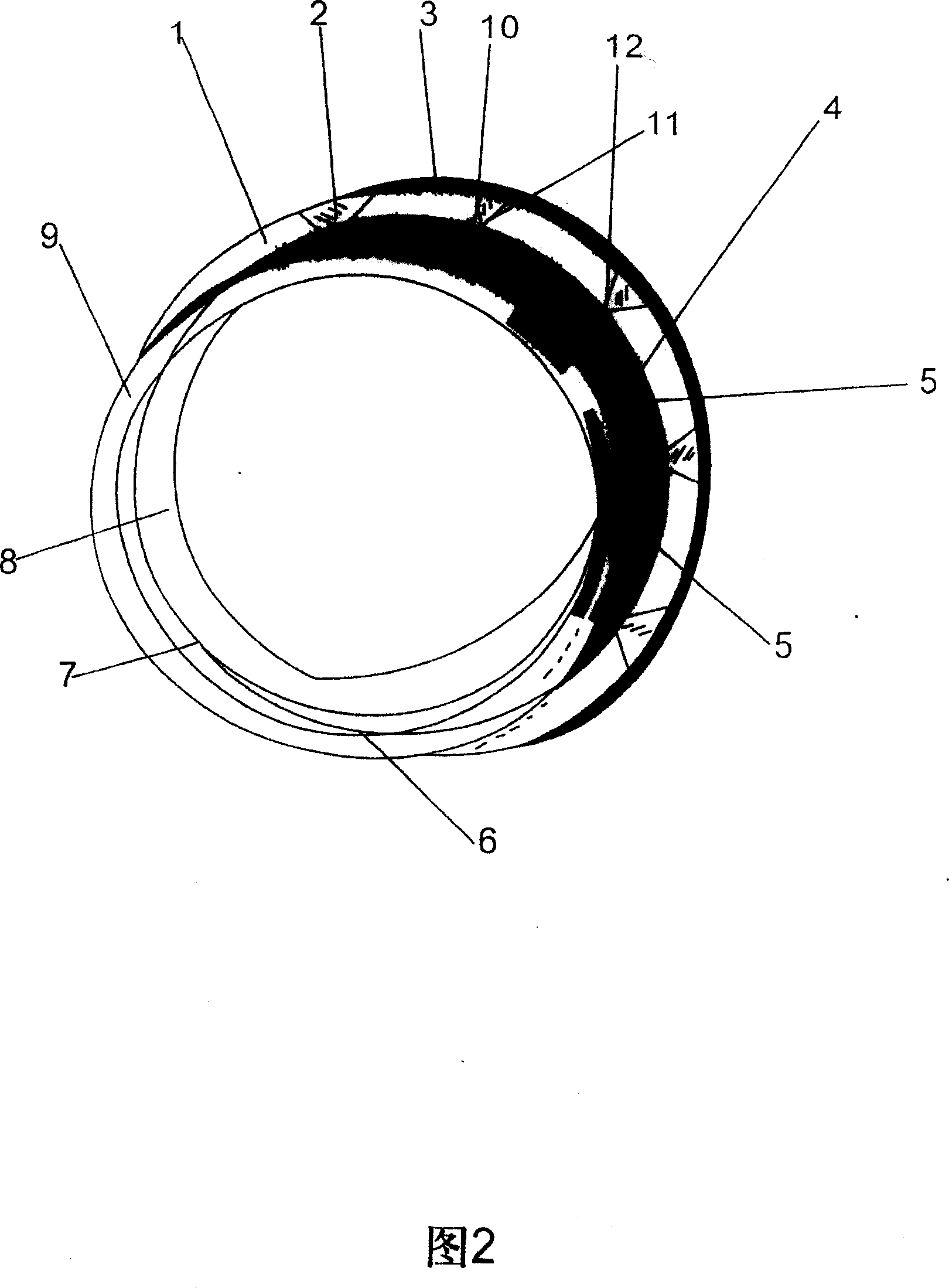

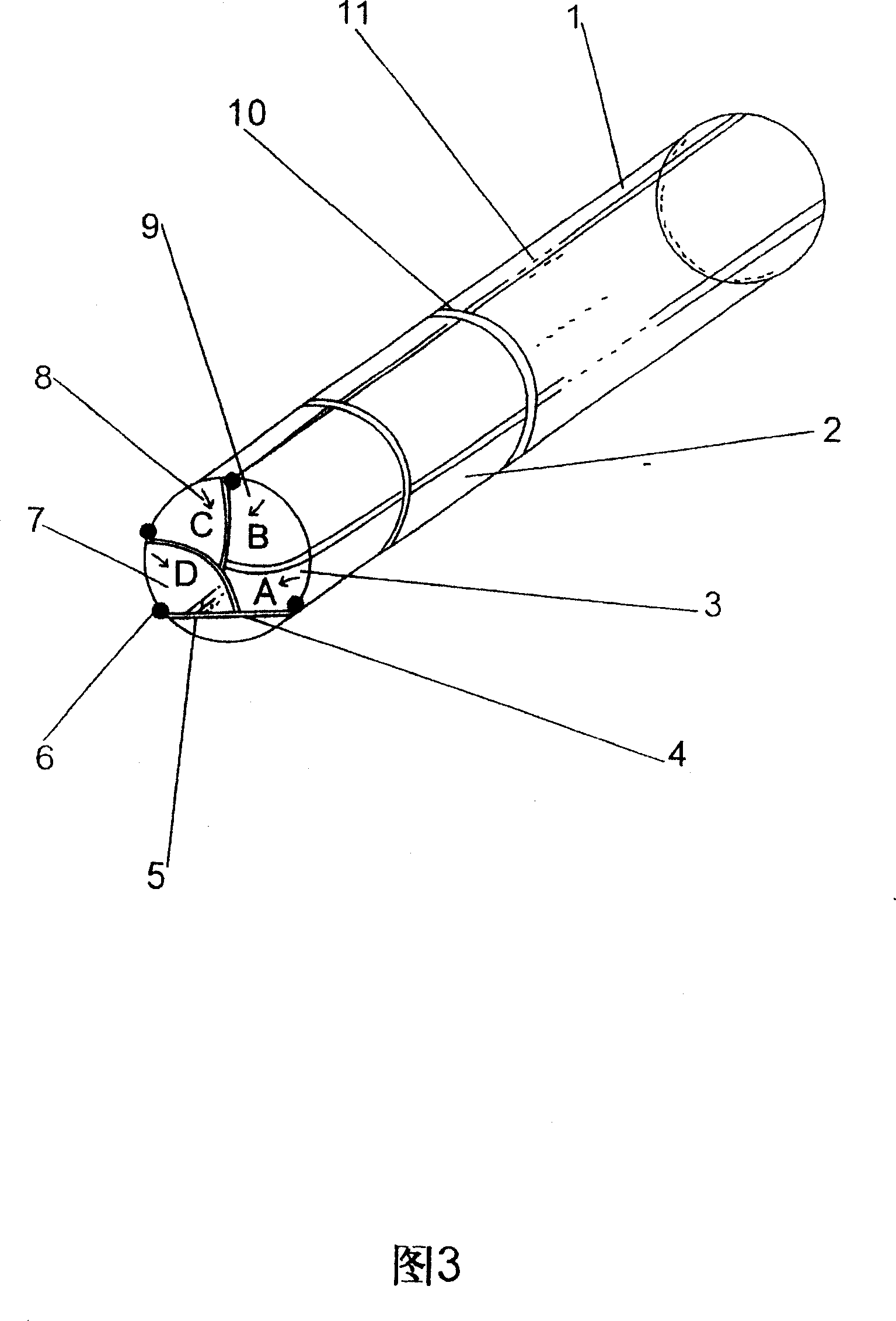

The present invention provides a railway train system in which passenger and cargo trains are arranged in a container train with a powerful driving force to run at a super-high speed; the container train runs in a vacuum or low vacuum or several branches (part) tunnel (pipe). A whole series of passenger trains or cargo trains are arranged in the container train. Passenger trains or cargo trains can enter or exit the container train automatically (with driving force) in stations; passengers can also enter each train carriage of the passenger train through an air outlet hermetic channel in a train platform. All along the train route emergency life-saving air pipelines, a plurality of hermetic doors and safety facilities are provided; hermetic doors and exhausting bags etc. are provided in and out of the train station. So that the vacuum environment and the in and out of passengers and cargo in the normal pressure environment are effectively and easily realized. The pressure in the carriage is normal pressure environment; a plurality of protective conditions are provided, (including two train shells (the container train shell, the passenger train shell), a middle layer and the related safety equipment and rescue channel). The system of the present invention is the first practical realization of long-distance transcontinental railway train passenger and cargo transporting with super-high speed in a vacuum condition. The present invention provides a significant meaning for saving traveling time, improving life quality and accelerating the passenger and cargo transporting.

Description

technical field [0001] The invention relates to a high-speed train and a railway transportation system for transporting a large number of passengers and goods, in particular to an ultra-high-speed railway train system running in a vacuum or almost a vacuum or a tunnel (pipe) containing only a small amount of air particles. Background technique [0002] After the conventional electric train using the wheel-rail system reaches a speed of about 400 kilometers per hour, it is difficult to greatly increase its speed due to the negative force of the wheel-rail and atmospheric resistance; The program is still in continuous research and development, and its test speed has exceeded 500 kilometers per hour. However, due to its reliability, safety and economic cost, there is still no practical, convenient and safe solution in all countries in the world. Low-cost long-distance passenger and cargo combined trunk railway type maglev high-speed railway train system. [0003] The present i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B61B13/10

CPCB61B13/10Y02T30/30Y02T30/00

Inventor 杨福顺

Owner 杨福顺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com