Automatic survey probe replacing device and method thereof

A technology of automatic replacement and stylus, applied in the field of precision measurement, can solve problems such as reports or literature that have not yet been found, and achieve the effect of solving the problem of large axial magnetic force, reducing the effect of axial magnetic force, and facilitating access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

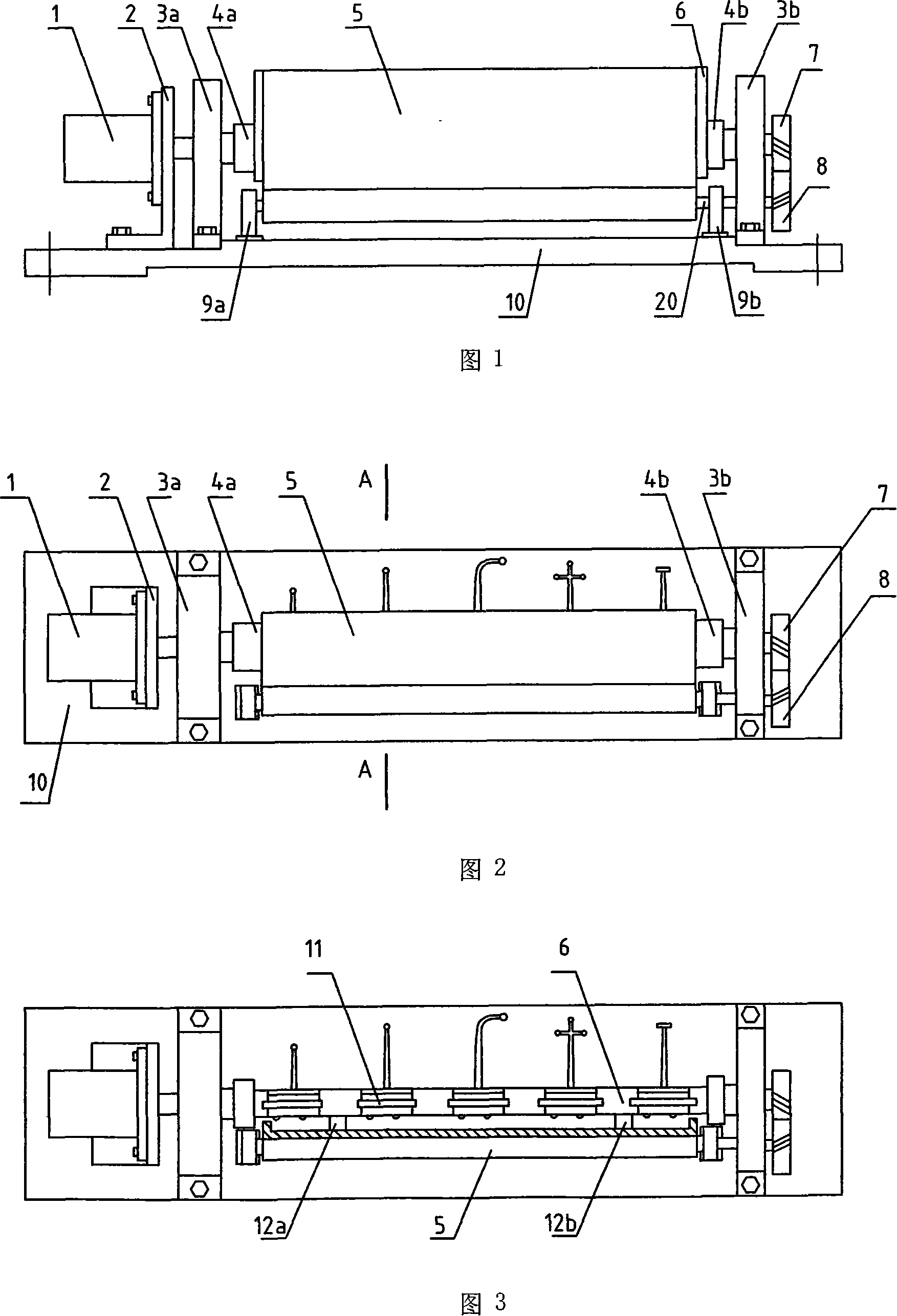

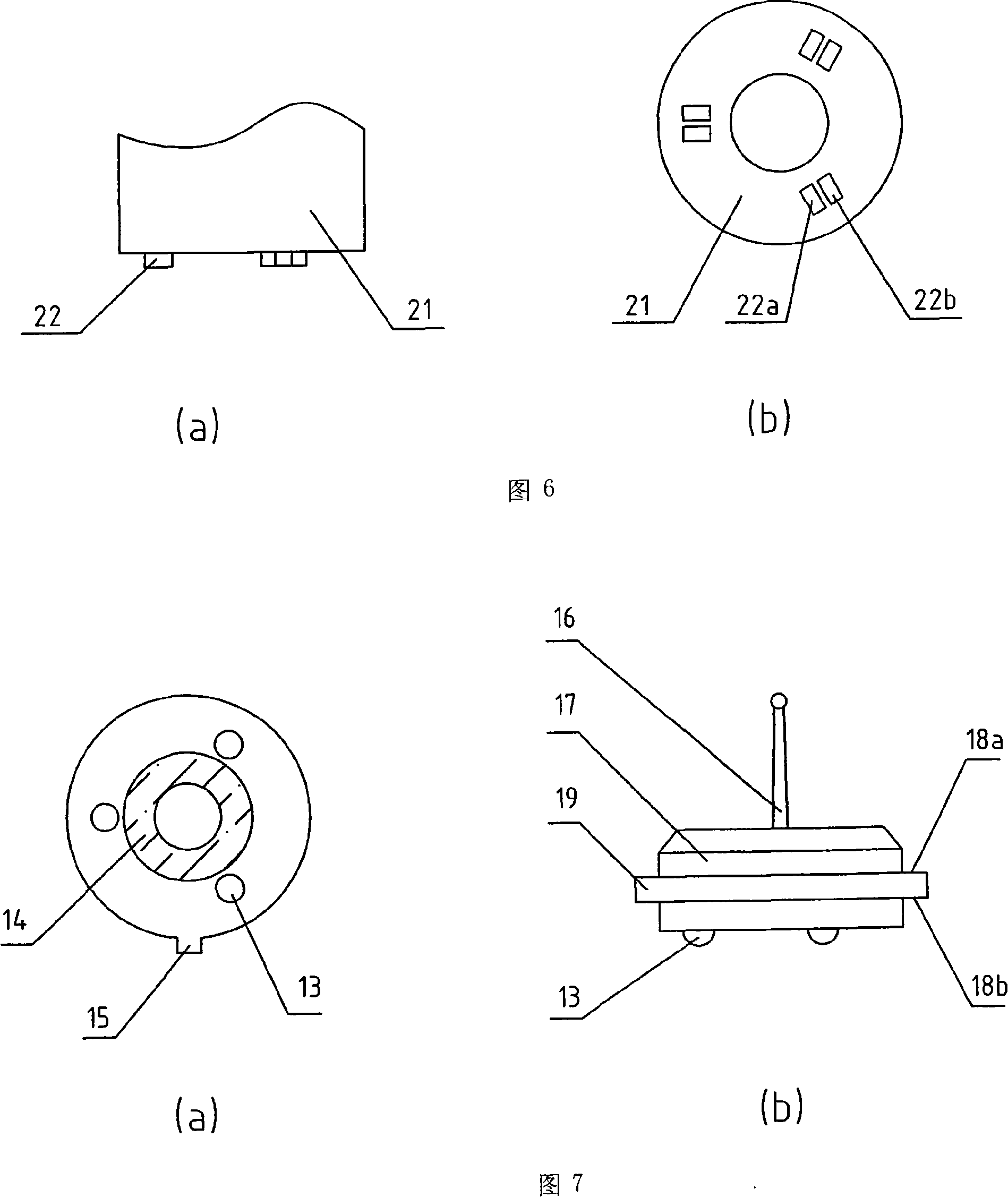

[0041] Embodiment 1: As shown in FIG. 1, the present invention is an automatic stylus replacement device, including a stylus 21, a stylus module 11, a stylus module storage rack 6, a protective cover 5, a control computer, and a stylus module. There is a positioning ball 13 at the bottom, which is equipped with a permanent magnet 14, which is related to the access control of the measuring machine stylus. The specially designed stylus storage rack is installed on the working table of the coordinate measuring machine through the bottom plate 10, which can be selected according to the measurement requirements. Placed at a suitable position on the work surface, the stylus 16 is fixedly mounted on the stylus module 11. In order to facilitate the replacement of the stylus 16, the stylus 16 is installed on the standard module board 17, which can be connected by thread or The standard stylus module 11 is made by directly soldering it on the module board, see Fig. 6b for details. In or...

Embodiment 2

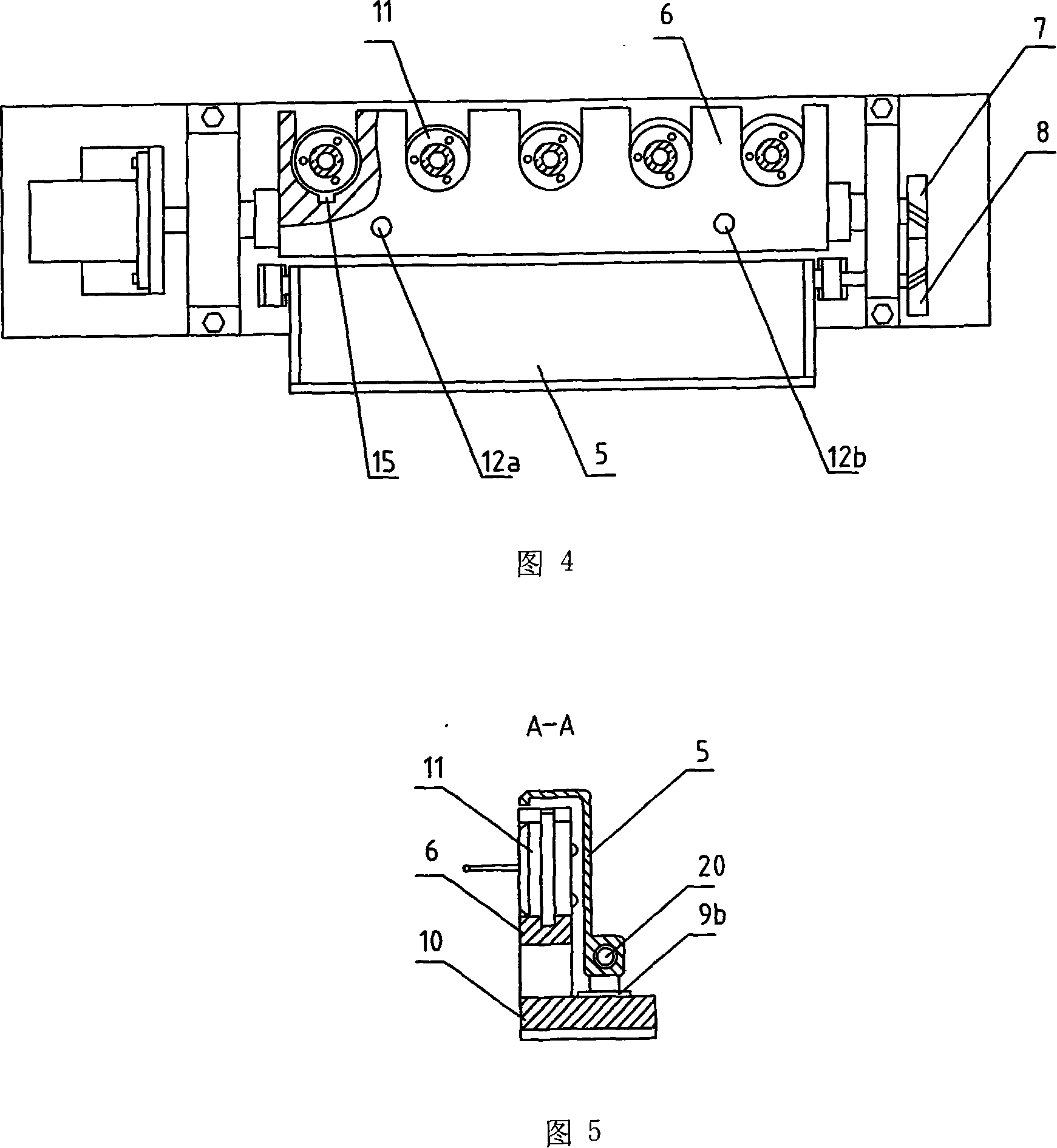

[0045] Embodiment 2: Referring to Fig. 3, the overall device is the same as that of Embodiment 1. The stylus module is a stylus module 11 with styli of different sizes and specifications fixedly installed, and the diameters of the outer circular bosses are also different. See Fig. 4. The diameters of the U-shaped grooves of the stylus module are also different and correspond to each other one by one. Since a plurality of stylus modules can be placed on the storage rack 6, it is stipulated that for a stylus of each specification, the stylus module can only be installed at the position of a U-shaped support seat of the storage rack, and multiple stylus modules are not allowed. The case where the needle module can be mounted on a U-shaped support. Otherwise, the measurement equipment will be wrongly installed with a stylus that does not meet the requirements, making the measurement impossible or the measurement result wrong.

[0046] FIG. 6 is a detailed structural diagram of th...

Embodiment 3

[0048] Embodiment 3: Referring to Fig. 3, the overall device is the same as that of Embodiment 1, in which the stylus module storage rack 6 is provided with 5 U-shaped grooves, which are respectively placed into the long and short spherical stylus and elbow. Stylus stylus, star stylus, disc stylus are commonly used types of stylus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com