Shaft sealing

A shaft seal and seal ring technology, applied in the field of vacuum pumps, can solve the problems of shaft seal damage, escape, failure, etc., and achieve the effect of good sealing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

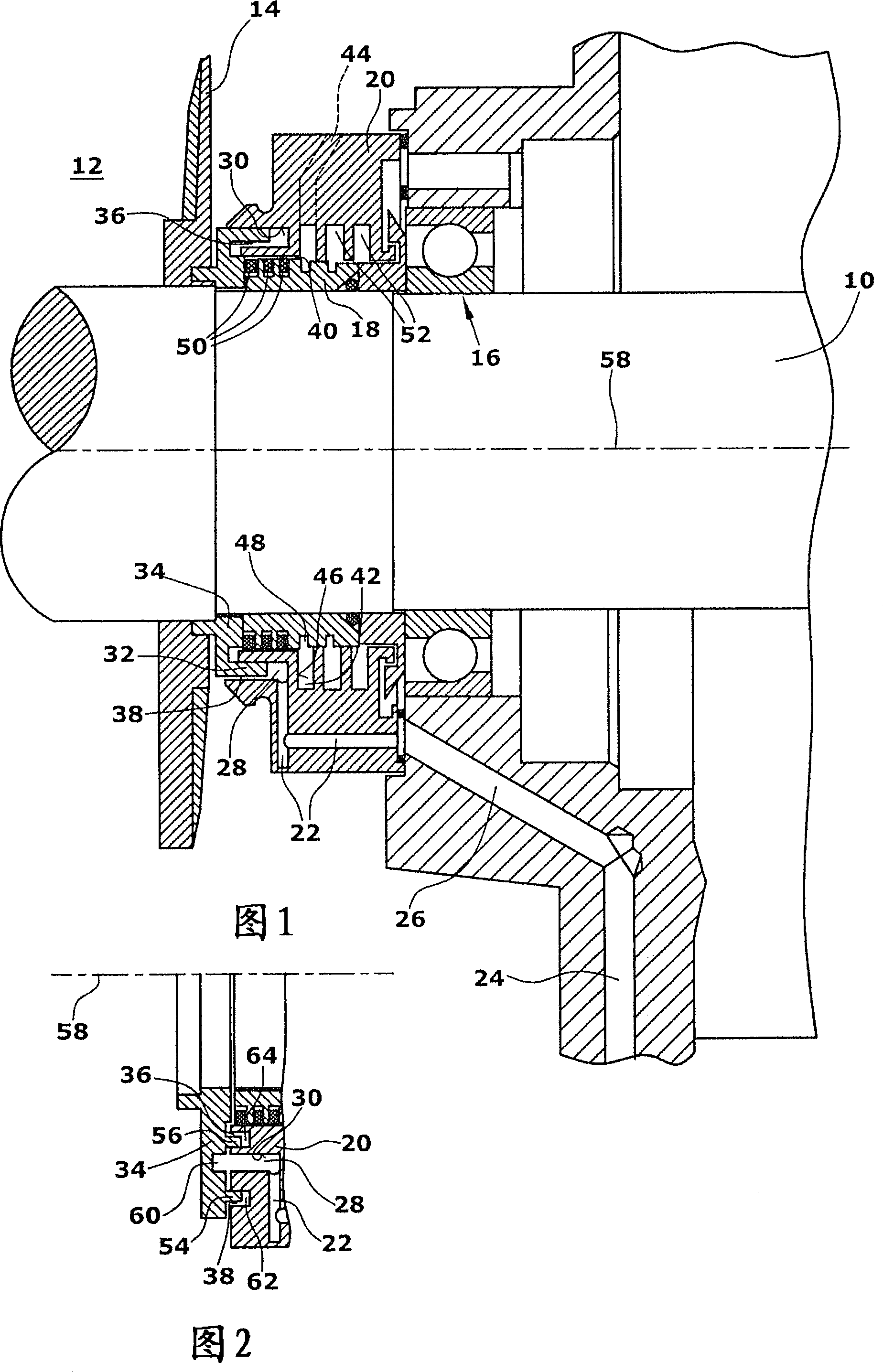

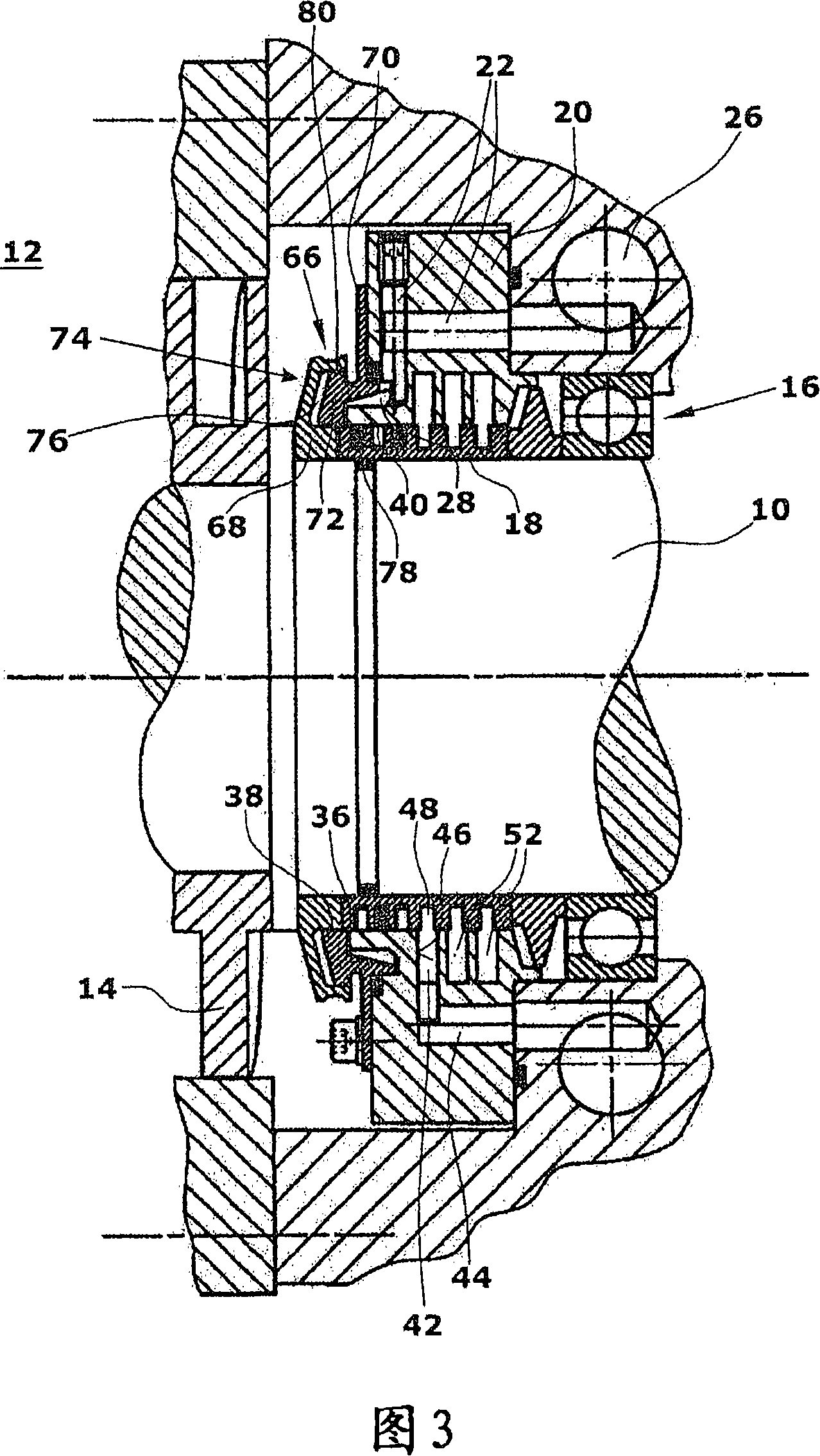

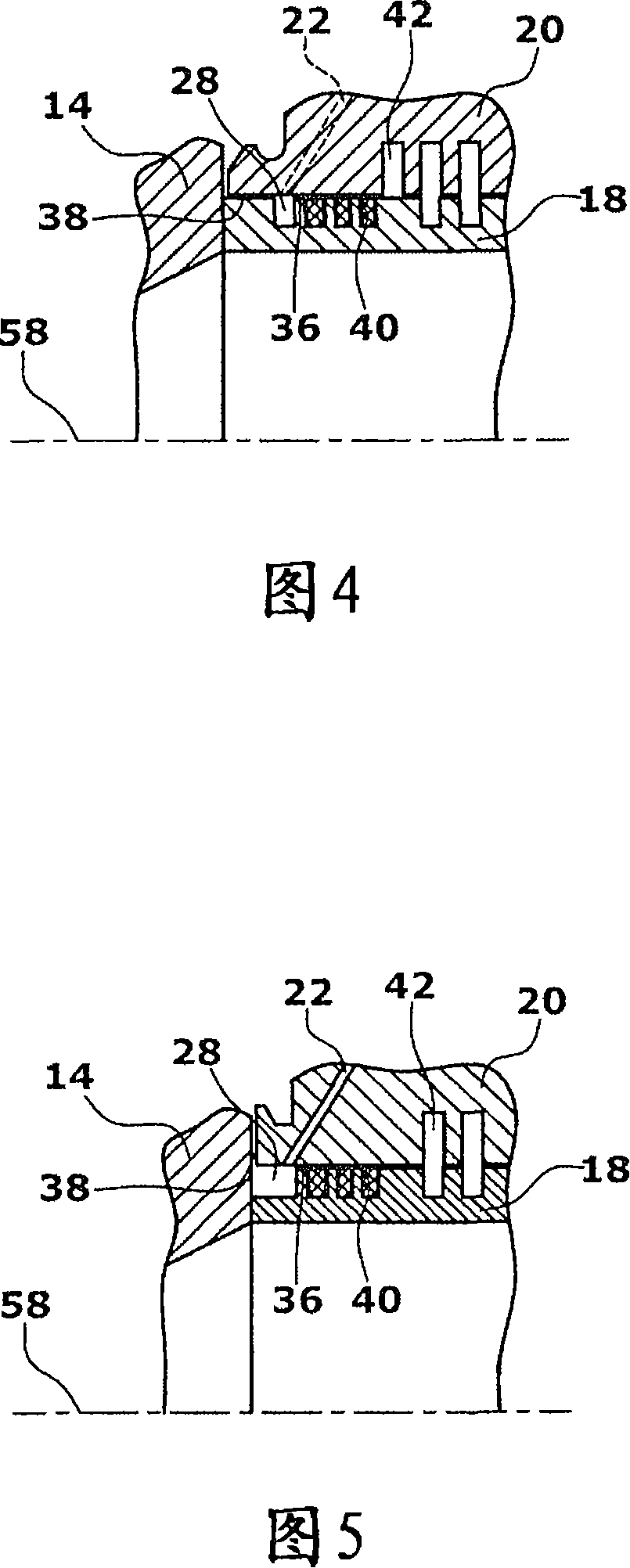

[0025] The rotor shaft 10 is connected on the suction chamber side or dry side 12 to a rotor 14 , in order to simplify the illustration, only one rotor blade of a rotor designed as a helical rotor is shown. Furthermore, the rotor shaft 10 is connected to a bearing 16 , which in the embodiment shown is a ball bearing. Bearing 16 is lubricated with oil, for example. A shaft seal according to the invention is arranged between the rotor 14 and the bearing 16 .

[0026] In a first embodiment ( FIG. 1 ), the shaft seal comprises an inner sealing ring 18 permanently connected to the rotor shaft 10 . The inner sealing ring 18 is surrounded by an outer sealing ring 20 which is arranged, for example permanently, in a housing, not shown. A supply channel 22 is provided in the outer sealing ring 20 , which is connected to a channel 26 provided in the housing 24 . Via channel 26 and supply channel 22 sealing gas may be supplied to sealing gas chamber 28 .

[0027] In the embodiment sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com