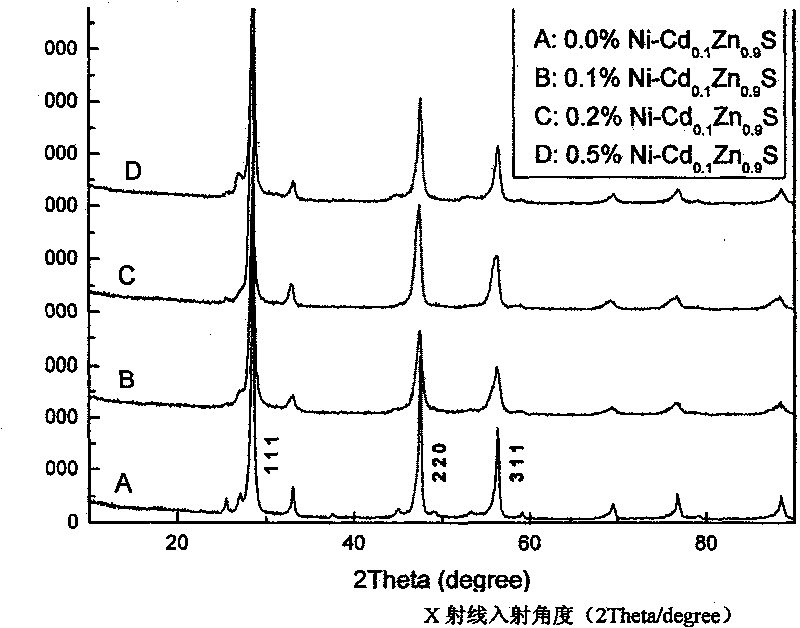

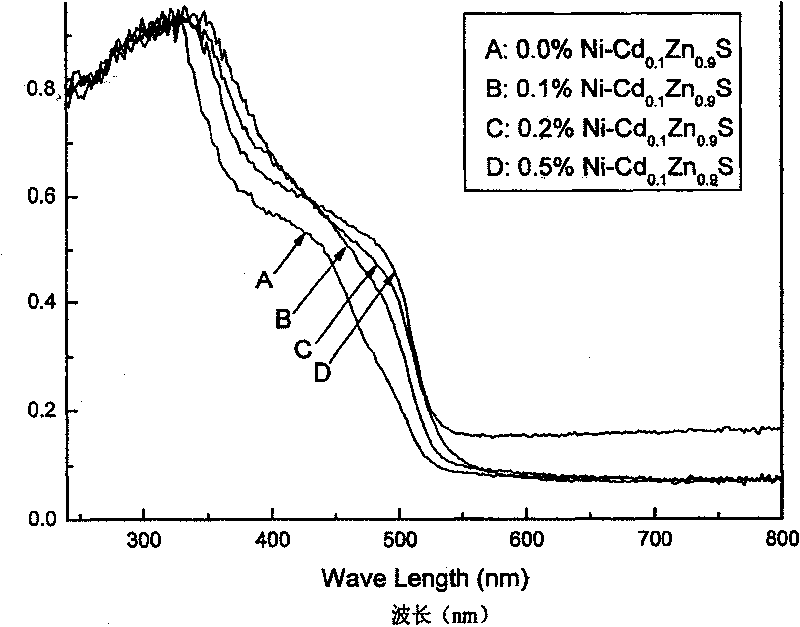

Ni doping Cd0.1Zn0.9S micrometre ball photocatalyst and preparation method

A photocatalyst and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of photocatalyst hydrogen production activity decrease, conduction band decrease, etc., and achieve improved photocorrosion resistance , improved hydrogen production activity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh ZnSO 4 ·7H 2 O: 5.17g, 3CdSO 4 ·8H 2 O: 0.51g, thioacetamide: 1.50g, dissolved in 50mL deionized water to form a mixed solution;

[0027] 2) Transfer the mixed solution to a hydrothermal kettle, place it in an oven after sealing it completely, and keep it at 160°C for 8 hours;

[0028] 3) Take out the hydrothermal kettle, and cool to room temperature naturally;

[0029] 4) The product was washed several times with deionized water, then dried in a vacuum oven at room temperature, and finally ground to obtain Cd without Ni-doped 0.1 Zn 0.9 S photocatalyst.

Embodiment 2

[0031] 1) Weigh ZnSO 4 ·7H 2 O: 5.17g, 3CdSO 4 ·8H 2 O: 0.51g, Ni(NO 3 ) 2 ·6H 2 O: 0.0102g, thioacetamide: 1.50g, dissolved in 50mL deionized water to form a mixed solution;

[0032] 2) Transfer the mixed solution to a hydrothermal kettle, seal it completely and place it in an oven at 160°C for 8 hours;

[0033] 3) Take out the hydrothermal kettle, and cool to room temperature naturally;

[0034] 4) The product was washed several times with deionized water, then dried in a vacuum oven at room temperature, and finally ground. Cd with a Ni doping amount of 0.1wt% can be obtained 0.1 Zn 0.9 S photocatalyst, its particle shape is a microsphere composed of nanocrystals.

Embodiment 3

[0036] 1) Weigh ZnSO 4 ·7H 2 O: 5.17g, 3CdSO 4 ·8H 2 O: 0.51g, Ni(NO 3 ) 2 ·6H 2 O: 0.0203g, thioacetamide: 1.50g, dissolved in 50mL deionized water to form a mixed solution;

[0037] 2) Transfer the mixed solution to a hydrothermal kettle, seal it completely and place it in an oven at 160°C for 8 hours;

[0038] 3) Take out the hydrothermal kettle, and cool to room temperature naturally;

[0039] 4) The product was washed several times with deionized water, then dried in a vacuum oven at room temperature, and finally ground to obtain Cd with a Ni doping amount of 0.2wt%. 0.1 Zn 0.9 S photocatalyst, its particle shape is a microsphere composed of nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com